Top Flite TOPA0708 User Manual

Page 12

12

ASSEMBLE THE FUSELAGE

Firmly pull on the elevators to check that the hinges

are securely glued.

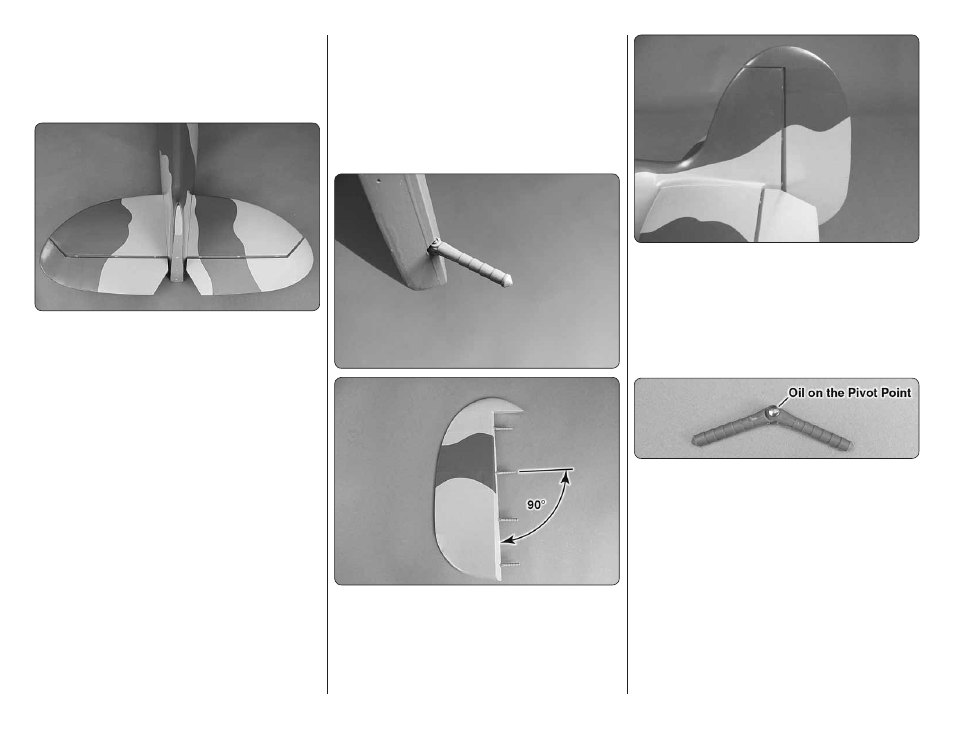

INSTALL THE STABILIZER

❏

1. Test fi t the two aluminum stabilizer tubes in the

fuselage and slide the stabilizers on the tubes. The

shorter tube goes in the front hole. If the aluminum tubes

are too tight to slide through the holes, take a sharp

hobby knife and gently scrape the inside of the holes.

During the manufacturing process a small amount of

resin or fi ller may be left behind in the hole.

❏

2. Once you are satisfi ed with the fi t of the stabilizer

halves, remove the stabilizer halves and the joiner tubes.

Use medium grit sandpaper to roughen up the aluminum

tubes. Clean the tubes with denatured alcohol and insert

both tubes back into the fuselage until the end exits on

the opposite side by approximately 1" [25mm].

❏

3. Gather everything required for gluing the stabilizer

halves to the fuselage including 30-minute epoxy, mixing

sticks, epoxy brush, 12" [304mm] long dowel or wire,

masking tape, denatured alcohol and small paper towel

squares. Mix up 3/4 oz. [22.1cc] of 30-minute epoxy.

Apply a generous amount of epoxy to the long side of

the aluminum joiner tubes. Pull the tubes through the

fuselage so that they are close to centered. Pour a small

amount of epoxy into both holes of one of the stabilizer

halves and using a dowel or wire, coat the inside of

the holes. Apply epoxy to the root rib of the stabilizer

and the fuselage. Insert the end of the aluminum tubes

with epoxy on them into the stabilizer and press the

stabilizer against the fuselage. Wipe off any excess

epoxy that may have squeezed out before it runs down

the fuselage. Quickly repeat the process on the other

side. Wipe off any excess epoxy with a dampened paper

towel and denatured alcohol. Use pieces of masking

tape to hold the stabilizer tight against the fuselage

until the epoxy cures.

❏

4. Without using any glue, install four hinges into

the rudder. Note that the pivot point of each hinge

must align with the center of the leading edge of the

rudder. To achieve this alignment, the hinges will be

fairly deep in the rudder. Also note that the hinges must

be perpendicular to the leading edge.

❏

5. Again without glue, test fi t the rudder to the fi n.

Move it left and right a few times to align the hinges.

The rudder doesn’t have to move very far, only 1-3/4"

[44mm] left and 1-3/4" [44mm] right measured at the

widest part of the rudder at the trailing edge. If there

is too much resistance, or if you are not able to move

the rudder left and right 1-3/4" [44mm], widen the gap

slightly between the rudder and fi n.

❏

6. Remove the rudder and all the hinges. Add a

small drop of oil to the pivot point on the hinges. This

will prevent the epoxy from adhering to the pivot point.

Make sure oil does not get on the gluing surface of the

hinge. If it does, clean the oil off with a paper towel

dampened with denatured alcohol.

❏

7. Please read the complete instructions in this step

before mixing up the epoxy. Mix up approximately ¼ oz.

[7.4cc] of 30-minute epoxy. Use a toothpick to thoroughly

apply the epoxy in the holes in the fi n and rudder. Use

the toothpick to get the epoxy out of the opening of the

holes in the rudder and fi n so it doesn’t get into the

pivot point. Wipe away any excess epoxy around the

outside of the holes with a paper towel dampened with

denatured alcohol.