Top Flite TOPA0708 User Manual

Page 17

17

❏

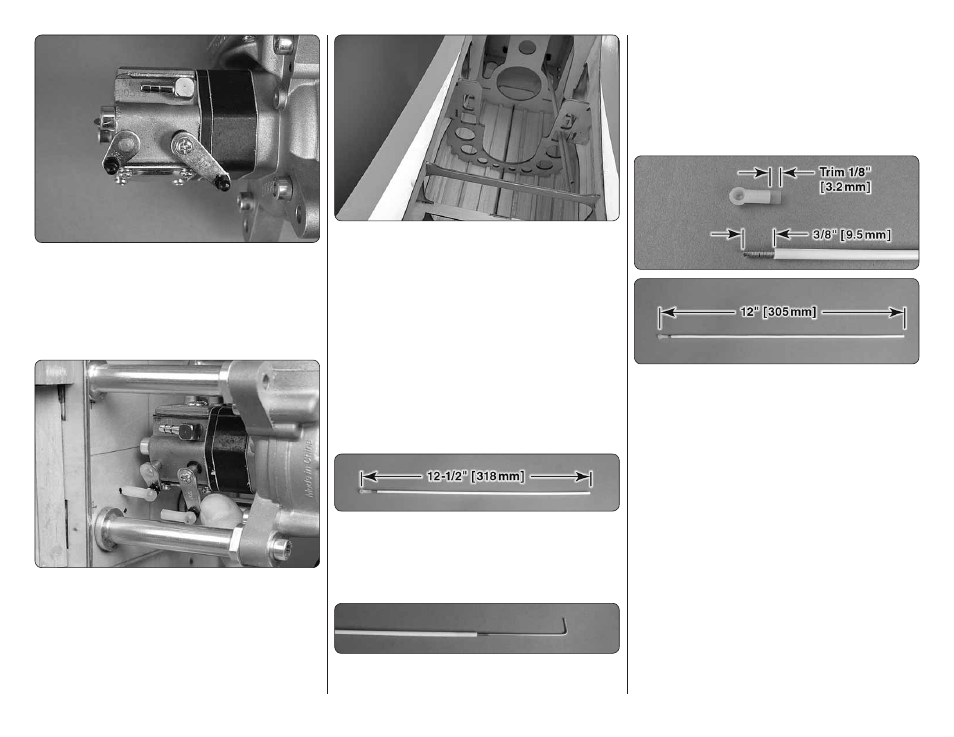

6. Install a 2-56 ball link ball on the choke arm and

secure it with a 2-56 nylon nut.

❏

7. Temporarily install the engine inverted on the

aluminum standoffs. Determine on which side of the

fuselage the throttle and choke servos need to be

installed.

❏

8. Snap a nylon ball socket onto both pivot balls.

Center the choke and throttle arms and mark the fi rewall

where the pushrods will need to pass through.

❏

9. Drill a 3/16" [4.8mm] hole at the marks on the

fi rewall for the throttle and choke pushrods. You may

fi nd it easier to remove the engine before drilling the

holes. Cut two 11" [279mm] long outer pushrod tubes

from the 36" [914mm] long outer pushrod tube. Use

medium sandpaper to roughen the outer pushrod tubes.

Clean the tubes with denatured alcohol and insert the

tubes into the previously drilled holes in the fi rewall.

Route the tube through the slot in the former until it is

fl ush with the front of the fi rewall. Use thin CA to glue

the tubes to the fi rewall.

❏

10. Apply a drop of threadlocker to the engine

mounting bolts. Reinstall the engine on the standoffs

using the bolts and washers supplied with the engine.

❏

11. To make a throttle pushrod, thread a 2-56 x 1"

[25mm] threaded rod approximately 3/8" [9mm] into the

end of the white inner pushrod tube. Thread a nylon ball

link socket onto the threaded rod. For the DLE engine,

trim the throttle pushrod 12-1/2" [318mm] long.

❏

12. Make a ½" [12mm] long L-bend at the non-

threaded end of the 2-56 x 6" [152mm] metal pushrod.

Thread the other end ¾" [19mm] into the end of the

throttle pushrod tube. The L-bend makes it easier to

thread in.

❏

13. Cut off the L-bend from the 2-56 x 6" [152mm]

pushrod. Insert the throttle pushrod into the throttle

outer pushrod tube. Attach the ball link socket to the

ball link ball on the throttle arm.

❏

14. To make the choke pushrod, trim approximately

1/8" [3.2mm] from the end of the nylon ball socket before

threading the 2-56 x 1" [25mm] threaded rod into the

end. Also trim the threaded rod so that 3/8" [9.5mm]

of the rod remains from the white inner pushrod tube.

Trim the choke pushrod 12" [305mm] long.

❏

15. Make a ½" [12mm] long L-bend at the non-

threaded end of the 2-56 x 6" [152mm] metal pushrod.

Thread the other end ¾" [19mm] into the end of the

choke pushrod tube. Cut off the L-bend from the 2-56 x

6" [152mm] pushrod. Insert the choke pushrod into the

choke outer pushrod tube. Attach the ball link socket to

the ball link ball on the choke arm.