Top Flite TOPA0708 User Manual

Page 16

16

❏

18. Slide a 3.5mm wheel collar followed by the tail

wheel and a second wheel collar on the tail gear wire.

Apply a drop of threadlocker to the threads of the 2.5

x 4mm machine screws. Secure the wheel collar on

the tail gear wire with the machine screws. Make sure

the screw in the outer wheel collar is tightened on the

fl at spot.

INSTALL THE ENGINE

❏

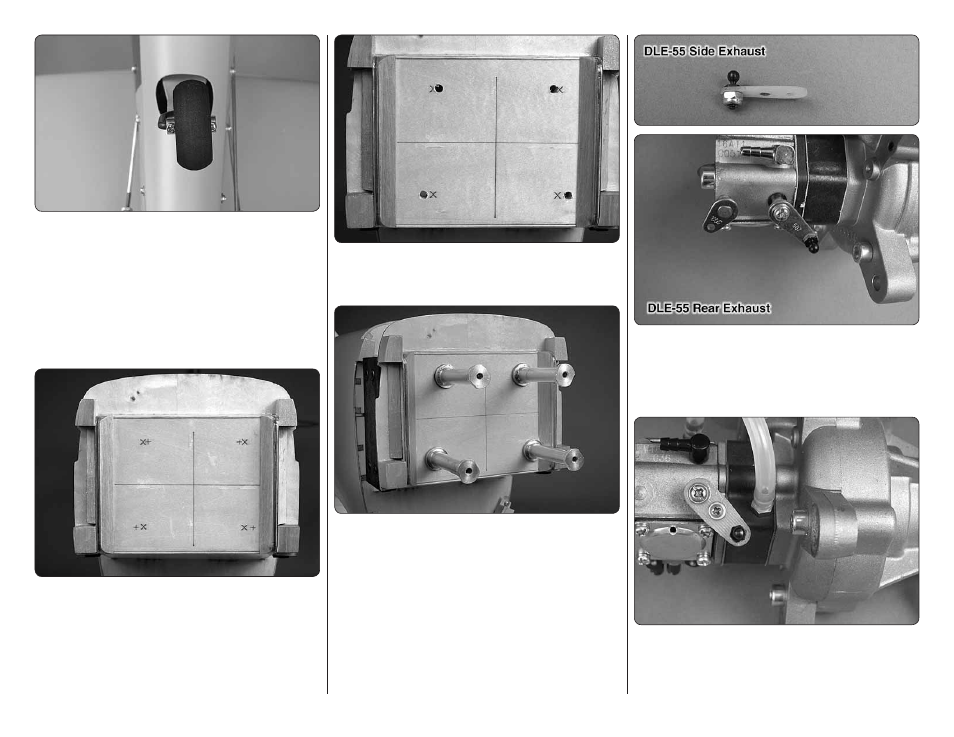

1. The fi rewall has two sets of engine mounting bolt

patterns embossed on it. The “+” are for the DLE-55

Rear Exhaust gas engine and the “X” are for the DA-50,

DLE-55 Side Exhaust, and O.S. GT55 gas engines. If

you are installing an engine with a different mounting

bolt pattern the fi rewall also has crosshairs embossed

on it to help locate the correct mounting location.

❏

2. Drill a 13/64" [5mm] hole through the fi rewall at

each of the appropriate locations marked with an “X”

or “+”.

❏

3. Insert four 10-32 x 1-1/2" [38mm] socket head cap

screws, #10 lock washers and #10 Fender washers (not

included) through the holes from the backside of the

fi rewall. Apply a drop of threadlocker to the threads of

each screw. Thread the engine standoffs onto the screws

and tighten them against the fi rewall. For a reference,

once the engine is installed, the front of the engine drive

washer should be approximately 6-3/4" (171mm) from

the front of the fi rewall.

❏

4. If installing the DLE-55 Side Exhaust engine, install

a 2-56 ball link ball on the throttle arm extension and

secure it with a 2-56 nylon locknut. If installing the DLE-

55 Rear Exhaust engine, install a 2-56 ball link ball on

the throttle arm and secure it with a 2-56 nylon locknut.

❏

5. On the DLE-55 Side Exhaust engine, use the

screw and nut supplied with the throttle arm extension.

Attach the extension to the throttle arm. Again, use

threadlocker on the threads.