Top Flite TOPA0965 User Manual

Page 18

18

❏

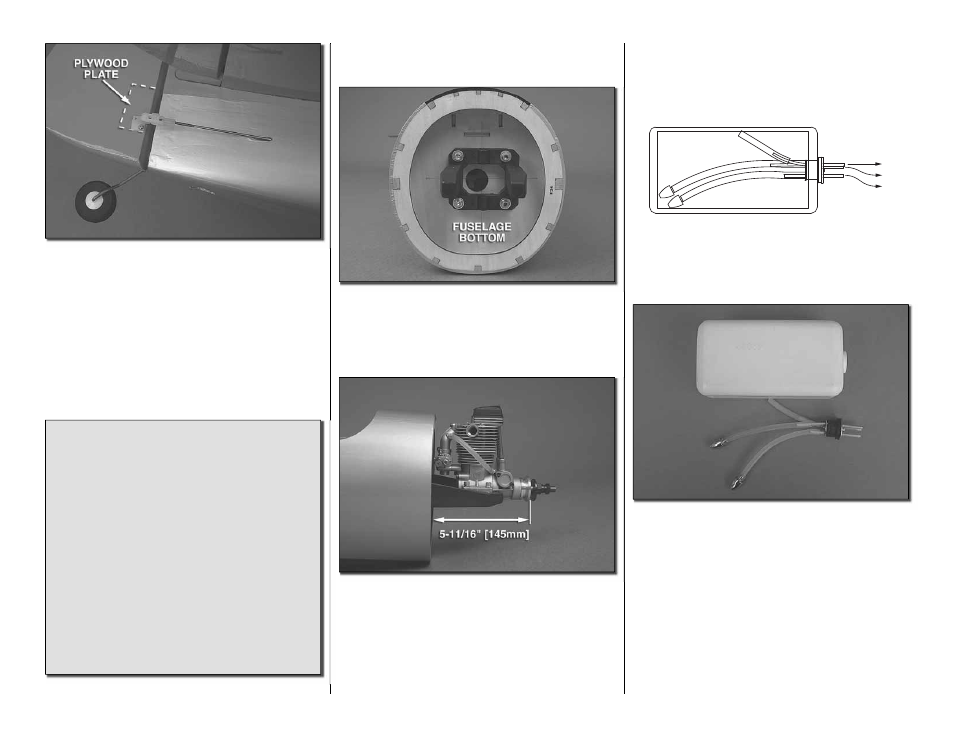

21. Screw a nylon clevis onto a .074 x 36" [914mm]

threaded wire 20 turns. Slide a nylon clevis retainer

onto the clevis. Install the clevis into the outer hole

of the control horn. Then slide the silicone retainer

over the clevis. Mark the location for the control horn

onto the rudder. Drill a 1/16" [1.6mm] holes into the

plywood plate in the rudder. Do not drill through the

rudder. Secure the horn to the rudder with #2 x 3/8"

[10mm] screws.

Did you know…The AT-6 Texan became the

classroom for the majority of the Allied pilots who

fl ew in World War II, and trained several hundred

thousand pilots in 34 different countries. Its basic

design was as a trainer, with the characteristics

of a high speed fi ghter, and was well suited to the

intermediary task of training pilots before letting

them loose in an actual fi ghter aircraft. Although

not as fast as a fi ghter, it was easy to maintain and

repair, had more maneuverability and was easier to

handle. A pilot’s airplane, it could roll, Immelmann,

loop, spin, snap, and vertical roll. It was used to

train pilots in all aspects of tactical operations, such

as dog-fi ghting, ground strafi ng, carrier landings,

and bombardment. It also included the capacity for

fi xed and fl exible guns, cameras, and just about

any other device that the military required.

INSTALL THE ENGINE FUEL TANK

AND THROTTLE SERVO

❏

1. Bolt the engine mount to the fi rewall with four

8-32 x 1" [25mm] socket head cap screw, #8 lock

washer and #8 fl at washer. Place your engine on the

mount and adjust the mounting rail position to match.

Then tighten the bolts.

❏

2. Position the engine on the mount so the distance

from the fi rewall to the front of the thrust washer

measures 5-11/16" [145mm]. Mark the location of

the engine on the mount. The Great Planes

®

“Dead

Center” Hole Locator (GPMR8130) works well for

this. Drill through the marks you have made with a

#29 or 9/64" [3.6mm] drill bit. Tap each hole with an

8-32 tap.

❏

3. Install the engine to the mount with four each,

8-32 x 1" [25mm] socket head cap screws, #8 lock

washers and #8 fl at washers.

A

B

C

A: TO MUFFLER

B: TO CARBURETOR

C: FILL LINE

❏

4. Assemble the fuel tank as shown in the sketch.

When tightening the center screw, be sure not to

overtighten it. You just want it snug enough to pull the

rubber stopper tight against the tank.

❏

5. Install silicone fuel tubing (not supplied) onto

the aluminum tubes from the fuel tank. One line with

the fuel clunk will feed to the fuel inlet at the needle

valve. The second line with the fuel clunk will be the

line to fi ll the tank. The remaining line will attach to

the pressure tap on the muffl er. The fi ll line should

be plugged after fueling with the aluminum fuel plug

provided with the kit.