Top Flite TOPA0965 User Manual

Page 17

17

❏

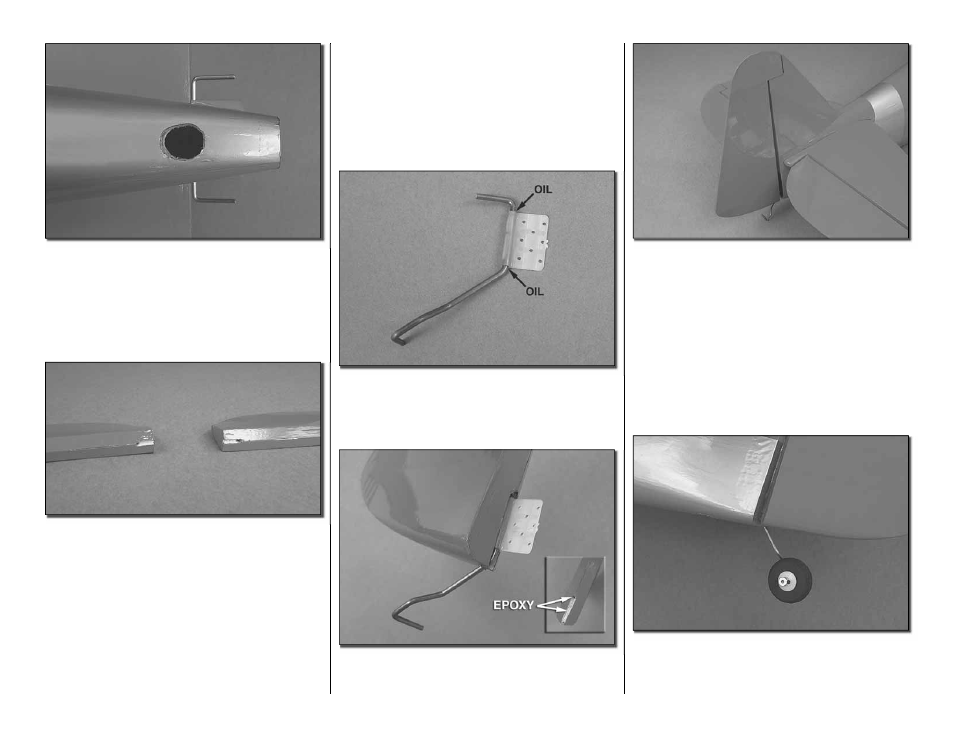

13. On the bottom of the fuselage there is a hole

that is large enough to get a forceps or small pliers up

to the clevis. Should you ever need to make additional

adjustments to the clevis, you can cut the covering

away to reveal the hole. The hole can be covered over

with the small piece of silver MonoKote included in

the kit.

❏

14. Apply a small amount of epoxy into the slot and

hole for the joiner wire in each elevator half.

❏

15. Cut nine 1" x 1" [25 x 25mm] hinges from a

CA hinge strip. Insert three hinges into the elevator. If

the hinges don’t remain centered, stick a pin through

the middle of the hinge to hold it in position. Slide the

hinges into the elevator.

❏

16. Remove any pins you may have inserted into

the hinges. Adjust the elevator so there is a small gap

between the LE of the elevator and the stab. The gap

should be small, just enough to see light through or to

slip a piece of paper through. Apply six drops of thin

CA to the top and bottom of each hinge. Do not use

CA accelerator. After the CA has fully hardened, test

the hinges by pulling on the elevator. Do this for both

elevator halves.

❏

17. Apply a couple of drops of oil into the nylon

bearing. This will prevent glue from getting into the

joint and causing the rudder to bind.

❏

18. Apply a small amount of epoxy into the hole and

the slot in the rudder. Insert the tail wheel assembly

into the rudder and allow the glue to cure.

❏

19. Install three hinges into the rudder the same as

done with the elevator. Test fi t the rudder to the fi n. If

necessary, use your modeling knife to adjust the hinge

slot for the nylon bearing. When installing the rudder,

the nylon bearing from the tail wheel assembly must

also fi t into the fi n. Once satisfi ed with the fi t, remove

the rudder. Put some epoxy onto each side of the

nylon bearing. Then re-insert the rudder back onto

the fi n. When you are satisfi ed with the fi nal fi t apply

six drops of thin CA to both sides of each hinge.

❏

20. Slide the tail wheel onto the tail wheel wire.

Secure it in place with a 1/8" [3mm] wheel collar

and 2-56 set screw. Be sure to use threadock on the

set screw.