Top Flite TOPA0135 User Manual

Page 32

❏ ❏

30. Use a sanding block and 150-grit

sandpaper to blend the upward facing surfaces of

the wing ribs and spars.

❏ ❏

31. Use the patterns provided on the plans to

make the Upper and Lower Flap Skins and the

Aileron Skins from four 1/16" x 3" x 36" balsa

sheets. Use the bevel gauge (assembled during

elevator construction) to mark the bevel line and

the rib end line on the inside surfaces of the skins,

then sand the bevel just as you did for the elevator

and rudder skins.Note: Be sure you make a right

and left set.

❏ ❏

32. Draw a line on the inside surface of the

upper flap skin 3/32" from the outboard tip. This will

indicate exactly where to position the skin over W-7

so you do not glue it to W-7B. Glue the upper flap

skin to the ribs. Hint: Refrain from using

accelerator during this step so that the CA you

use to glue on the

bottom flap skin will not

prematurely cure.

❏ ❏

33. If building flaps, push a pin between W-2B

and W-2 through the Upper Flap Skin about 1/8"

from the end of the ribs. This “point” will be used

later as a reference of where to cut the flap root

away from the wing.

❏ ❏

34. Glue the lower flap skin to the wing

and the trailing edge of the upper flap skin with

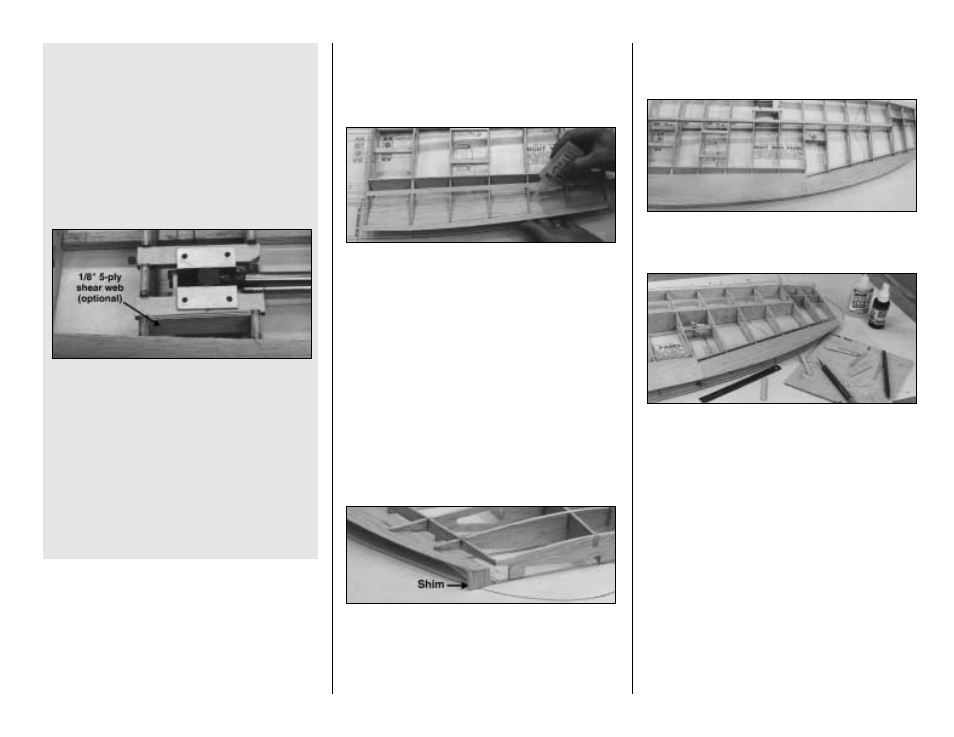

thick CA.

❏ ❏

35. Wet the outside surface of the top aileron

skin. Position it on the wing and glue it only to ribs

W-7B - W-10. Cut a piece of scrap balsa so that

when inserted in between the skin and the building

board it raises the skin in alignment with the tip of

the aft outer spar. Insert the shim, then glue the

aileron skin to the rest of the ribs. Leave the shim

in place until the wing is removed from the

building board.

❏ ❏

36. Wet the outside surface of the other

aileron skin and glue it to the upper skin

and ribs.

❏ ❏

37. Custom fit, then glue eight 1/16" balsa

Vertical Grain Shear Webs to the rear of the main

spars between all ribs except W-1 and W-2, and

W-2 and W-3. NOTE: It’s still important to keep the

wing on your flat building board. When you remove

two crossed pins to glue in a shear web, replace

one pin by pushing it through the shear web and

spar into the building board.

❏ ❏

38. Remove the wing from the building board.

Carefully trim off all jig tabs except the jig tabs on

W-1 and W-11. Sand the ends of the spars and the

flap sheeting flush with W-1.

Return to step 1 to build the other wing panel.

Use the other half of the wing plan and

remember to build a right and a left wing panel.

- 32 -

wheels will retract fully into the wheel well. With

the CJM retracts and the modifications to the rib

doublers shown in the sketches, the strut

protrudes outside the wing skin about 1/16" to

1/8". It may be possible to fully enclose the wheel

and strut inside the wheel well by deepening the

notches in the plywood rib doublers W-5R but

this is not recommended as it will weaken the

structure.

❏ ❏

28. Make adjustments to the notches in the

doublers if required, then use 30-minute epoxy to

glue the retract rails in position.

❏ ❏

29. (Optional) Make a Front Retract Rail

Sheer Web from a 2-1/2" wide piece of 5-ply

aircraft plywood (not supplied). Glue it to the

front retract rail and the rib doublers with

30-minute epoxy. NOTE: This front retract rail

sheer web is recommended for solid strut type

retracts or flyers who fly off of rough grass fields

but is optional and not required for coil type

wire struts.

Retract installation will be completed after

the wing panels are joined. This will allow you to

insure that both installations are identical by

comparing the two and making small

adjustments if required.