Install the engine – Top Flite TOPA0135 User Manual

Page 26

❏

11. Trim the ends of the aft bottom sheeting

even with F-9 and F-5D.

❏

12. Use a sanding block to sand the aft fuse

sheeting flush with the stringers so it tapers to the

bottom edge of the fin post.

❏

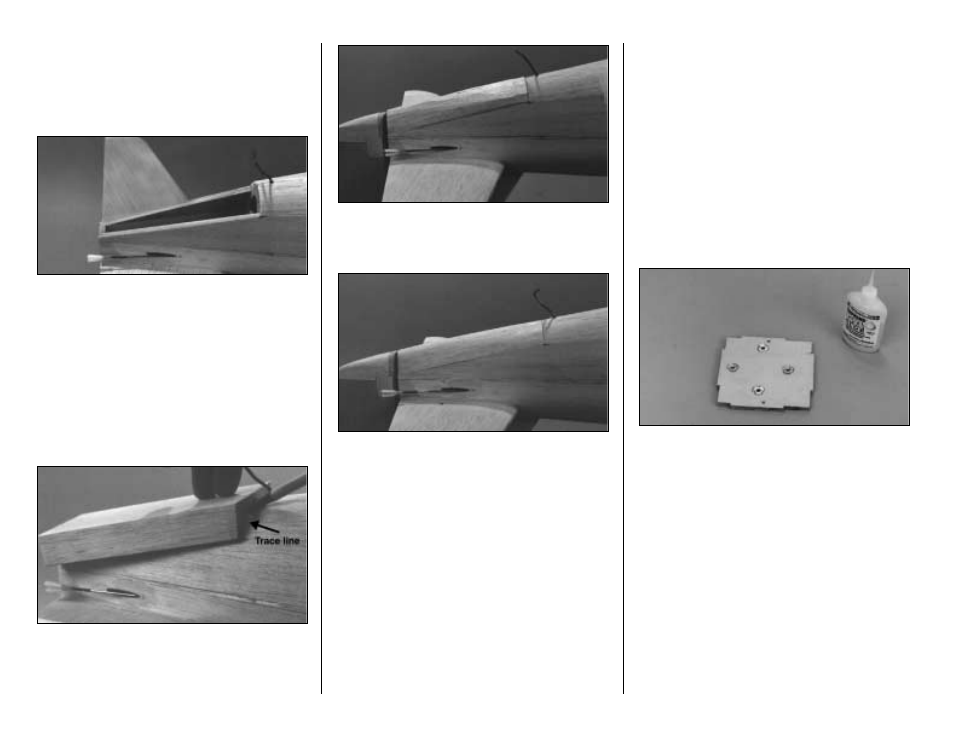

13. Bevel the front edge of the 1" x 2-1/2" x 7"

Aft Fuse Block to fit flush against 9-B. Sand the

aft edge flush with the fin post.

❏

14. Put the block on the fuselage and trace

around the underside and forward edge to form a

rough cutting outline. Tape the rudder in position

so that you can trace the outline on the aft edge of

the block.

❏

15. Remove the block, then use a hobby knife

and a razor plane to carve the shape to match the

outline you traced. Glue it in position when

satisfied with the shape.

❏

16. Continue shaping the aft fuse block to blend

with the fuse. Temporarily install the rudder, then

shape the aft fuse block and the rudder to blend

smoothly with the fuse.

❏

17. Use 30-minute epoxy to glue the 1/2" x 7/8"

x 1-1/4" Maple Wing Bolt Blocks in the fuselage

at the location shown on the plans.

Note: We will sheet between F-1 and F-2 when

we finish sheeting the belly pan.

INSTALL THE ENGINE

There are a variety of options when it comes to

engine selection. Our prototype P-47 weighed

approximately 10 lbs and flew extremely well with

the Super Tigre .75 2-stroke. When using a 1.20

4-stroke engine, due to the large amount of power

available the P-47 will have a tendency to climb as

full power is applied. This condition can be

controlled by adding an additional one degree of

down thrust to the engine.

NOTE: The following sequence shows the

installation of a Super Tigre .75 engine with the

cylinder mounted at a 45 degree angle towards

the bottom of the fuse. This orientation allows the

exhaust port of a 2-stroke engine to be connected

to a Top Flite In-Cowl Muffler and the engine

exhaust to exit near the bottom of the fuse.

❏

1. Drill four 7/32" holes through the laminated

Firewall for the engine mounting bolts at the

marked locations. Insert four 8-32 Blind Nuts into

the holes from the aft side and seat them with

gentle taps from a hammer. Wick thin CA around

the flange of each nut to secure it in position.

Avoid getting CA into the threads.

❏

2. Remove the spacer bar from the back of both

Engine Mount Halves and trim off any burrs.

Temporarily bolt the engine mount to the firewall

with four 8-32 x 1-1/4" Socket Head Cap Screws

with #8 Lock Washers and #8 Flat Washers.

Place the engine between the rails, adjusting the

width of the rails accordingly.

- 26 -