Top Flite TOPA0135 User Manual

Page 22

❏

5. After carefully aligning the holes, glue both

2-C’s to the forward surface of F-2B. Inspect all the

glue joints and add small fillets of medium CA

where each former meets the crutches.

❏

6. Glue the remaining lower formers 6-B

through 8-B to their respective upper formers.

Use a straightedge to maintain vertical alignment

between top and bottom formers. Hint: For better

bonding with the sheeting, lightly sand the formers

edges so that they are slightly beveled to match

the angle of the fuse toward the tail.

❏

7. Drill a 5/64" hole through the two

forward punch marks in the die-cut 1/8" plywood

Tail-wheel Deck (TW) and a 9/64" hole through

the aft punch mark. Insert 9-B into TW and glue

them to the fuselage as shown on the plans. Glue

5-D to the crutches.

❏

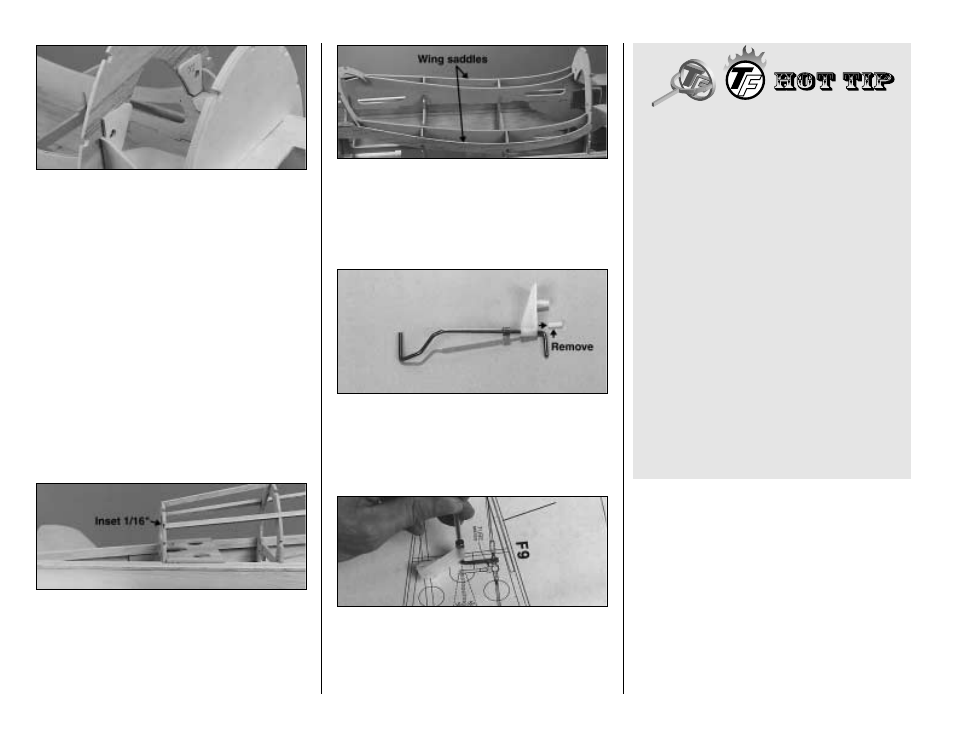

8. Glue three 3/16" x 3/16" x 24" stringers in the

aft former notches; one in the bottom and one more

in each middle notch as shown in the photo.

NOTE: The two side stringers at former F-9 do not

end at the aft edge of F-9 but are inset 1/16". Use a

straightedge as you glue in the stringers to keep

the formers in vertical alignment.

❏

9. Test fit the die-cut 3/32" balsa Wing Saddles

to the formers, then glue them in position.

TAIL GEAR INSTALLATION

❏

1. Cut the Aft Post flush with the nylon Tail

Wheel Bracket.

❏

2. Use a pliers to flatten 1/4" of one end of the

1/8" x 5/8" Brass Tube. Slide the tube on the Tail

Wire and check the parts over the fuselage top

view to make sure they match up well. Use silver

solder to solder the brass tube to the top of the

tailwheel wire.

❏

3. Mark the location of the Metal Ball on the end

of the brass tube and drill a 1/16" hole at the mark.

❏

4. Attach the ball permanently to the tail gear

with the Small Nut provided. Put a drop of epoxy

on the threads to prevent it from coming loose.

❏

5. Use the 4-40 Set Screw to lock the Collar at

the height shown on the fuselage side view, but

orient the set screw so small adjustments can be

made later during construction if required.

❏

6. Roughen the tubular Nylon Bearing on the

tailwheel wire with coarse sandpaper.

SILVER SOLDERING

Use this process when soldering metal to metal, such

as brass tube to wire, or pushrod ends to wire.

A. Thoroughly clean the items to be soldered with

alcohol or degreasing solvent. Pay special attention to

the inside of the threaded brass couplers.

B. Roughen the area to be soldered with fine

sandpaper, then clean again.

C. Assemble the items to be soldered.

D. Apply a small amount of soldering flux. Acid based

liquid flux works best when one or more of the items

is steel.

E. Heat the metal with a soldering gun or iron and

apply solder to the metal. The metal must get hot

enough to melt the solder and the solder must flow

freely into the joint.

F. Do not move the parts until the solder has cooled.

G. Test the joint by pulling hard.

H. Clean off the excess flux with alcohol or solvent.

Coat the parts with a very fine film of oil.

- 22 -