Top Flite TOPA0135 User Manual

Page 23

❏

7. Cut two 3" long sticks from one of the

approximately 6" long scrap pieces of 3/16" x

3/16" stringers leftover from the top of the

fuselage. Bevel one end of each stick, then glue

one of them to the side of middle stringer on the

very bottom of the fuselage. The other one will be

glued on at step 11.

❏

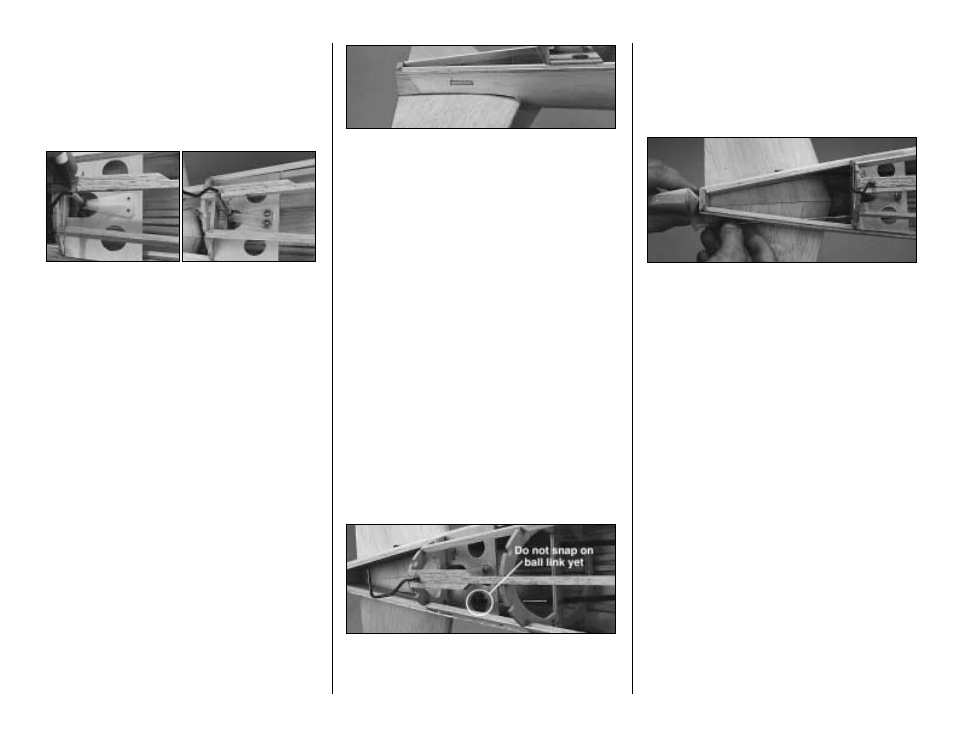

8. Place the tailwheel assembly on the tailwheel

brace with the nylon bearing tube next to the

stringer. Mark the location with a pen then cut a

notch in the stringer for the nylon bearing.

❏

9. Test fit the tailwheel assembly with the

bearing in the notch. Rotate the tailwheel wire and

check for binding. Make adjustments if necessary.

❏

10. Put a few drops of 30-minute epoxy in the

holes of the plywood tailwheel brace and the bolt

holes of the nylon bracket. Screw the nylon

bracket to the brace with two #4 x 3/8" Sheet

Metal Screws.

❏

11. Force some epoxy into the notch of the

stringer and around the nylon bearing being

careful not to get any epoxy inside the tube. Glue

the remaining 3/16" x 3/16" x 3" stick to the other

side of the stringer to lock the nylon bearing

into position.

❏

12. Cut the .074" x 36" Threaded One End Rod

to approximate length by removing 7" from the

non-threaded end. Thread a Dual-Ended Ball

Link 14 full turns onto the threaded end.

❏

13. From the 6-1/2" long piece of inner pushrod

tube, cut 11 pieces approximately 3/8" in length

and slide four of them onto the rudder pushrod,

spaced as shown on the plans.

❏

14. Mark and cut the rudder and elevator

pushrod exits where shown on the fuselage plans.

Bevel the exits with a sharp knife or a round file to

allow the outer pushrod tubes to exit at the angle

shown on the plans.

❏

15. Place two 36" long grey Outer Pushrod

Tubes over the Elevator Pushrod Tube and

Forward Rudder Pushrod Tube drawings on the

top view of the fuselage plans. Cut them a few

inches longer than length shown. Use 220-grit

sandpaper to roughen the outside of the tubes so

glue will stick to them.

❏

16. From one of the short cut-off pieces of 36"

pushrod tube, cut a 5" long piece for the Aft

Rudder Pushrod Tube and sand the outside.

❏

17. Slide the forward rudder pushrod tube and

the elevator tube through the holes in the formers

and position them as shown on the plans with the

excess length forward of F-4 Note: Remember

you are looking at the top view of the plans.

Position the pushrods on opposite sides of the

fuse, when looking at the fuse from the bottom.

❏

18. If you haven’t already done so, cut the

rudder hinge slots. Temporarily install the rudder

onto the fin.

❏

19. Install the Forward Rudder Pushrod

through the slot in the rear of the fuselage. Position

the dual-end ball link on the ball but do not snap

it on yet.

❏

20. Thread a Nylon Clevis onto the .074" x 12"

pushrod then place it over the Aft Rudder Pushrod

drawn on the plans and cut it 1/8" longer than shown.

❏

21. Temporarily snap a Small Control Horn

onto the clevis and slide a Threaded Coupler on

the end of the rod. Slide the control rod through the

pushrod exit in the aft end of the fuselage and

place the control horn on the rudder in the position

shown on the plans.

❏

22. Observe the location of the threaded

coupler and see if the length of the pushrod is

correct. With the rudder and tailwheel in neutral

position the threaded rod should be able to

screw into the dual-end ball link about 3/16".

Make adjustments to the length of the pushrod if

required.

❏

23. Once the threaded coupler is soldered to

the pushrod and the system is hooked up and

closed in, some adjustment may be made by

screwing or unscrewing the clevis but the more

accurate it is now, the less adjustment you may

have to make later. Slide one of the 3/8" spacers

onto the aft rudder pushrod, then use silver solder

to solder the threaded coupler onto the pushrod.

- 23 -