0 maintenance (cont'd), Warning – Reznor CAUA Users Manual User Manual

Page 4

Form O-CAUA, Page 4

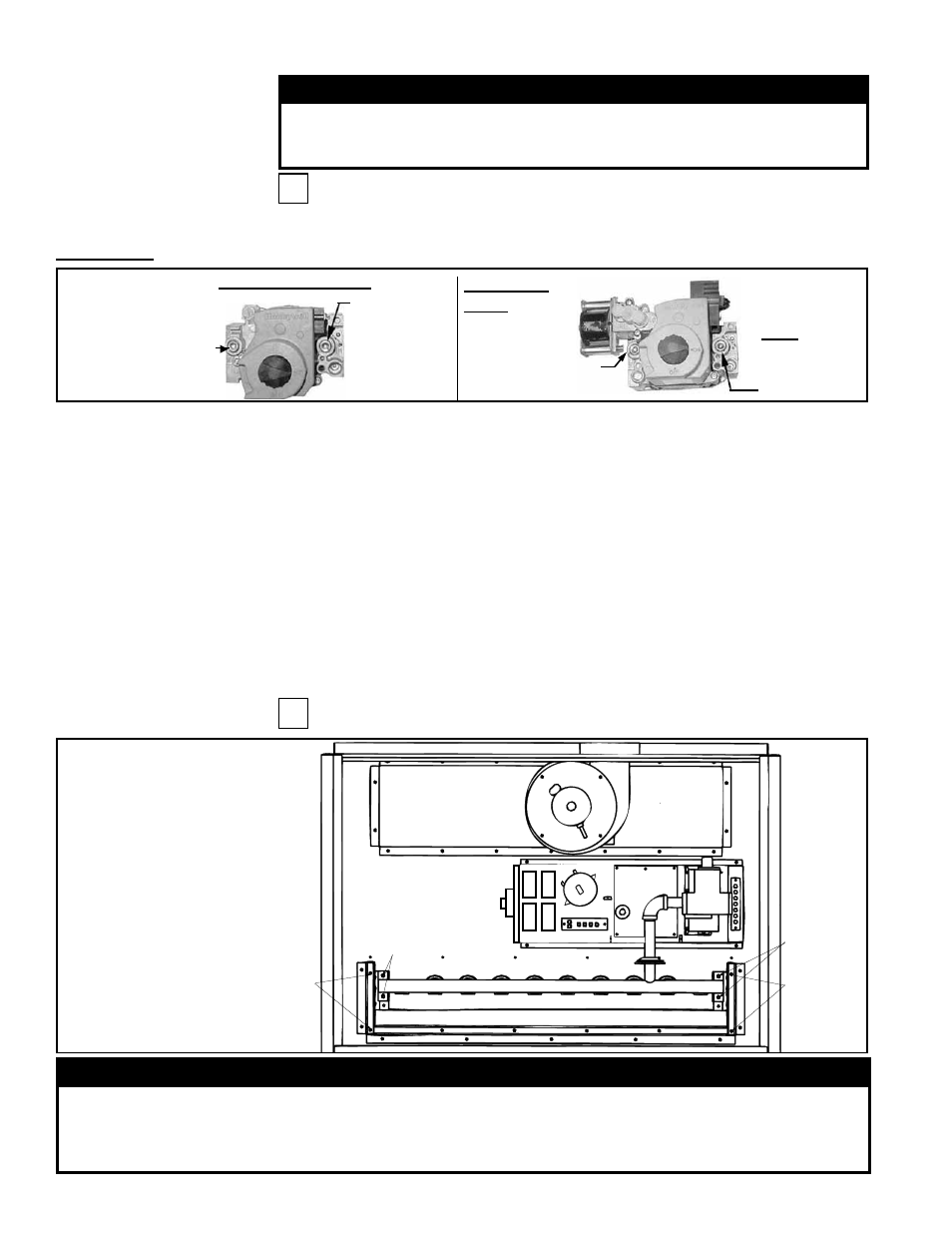

2.2.3 Gas Valve

Single-Stage Valve

Two-Stage

Valve

1/8" INLET

Pressure Tap

1/8”

Outlet

Pressure

Tap

1/8" INLET

Pressure Tap

1/8”

Outlet

Pressure

Tap

FIGURE 2

2) With the manual valve turned off to prevent flow to the gas valve, connect a

manometer to the 1/8” inlet pressure tap in the valve.

NOTE: A manometer (fluid-

filled gauge) with an inches water column scale is recommended.

3) With the field-installed manual valve remaining closed, observe the manometer

for two to three minutes for an indication of gas pressure. No pressure should be

indicated on the manometer.

If the manometer indicates a gas pressure, the field-installed manual gas valve

must be replaced or repaired before the combination gas valve can be checked.

4) If the manometer does not indicate gas pressure, slowly open the field-installed

manual gas valve. After the manometer's indicated gas pressure has reached

equilibrium, close the manual shutoff valve. Observe the gas pressure. There

should be no loss of gas pressure on the manometer. If the manometer indicates

a loss of pressure, replace the combination gas valve before placing the heater in

operation.

WARNING

The operating valve is the prime safety shutoff. All gas supply lines

must be free of dirt or scale before connecting to the unit to ensure

positive closure. See Hazard Levels, page 2.

2.0 Maintenance

(cont'd)

2.2 Maintenance

Procedures

(cont'd)

S

Remove external dirt accumulation and check wiring connections.

The combination gas valve must be checked annually to ensure that the valve is shut-

ting off gas flow completely.

2.2.4 Burner

Maintenance

WARNING

Excessive dirt buildup on and inside the burner ports could cause fuel gas to spill out of the back

of the burner tube causing gas odor inside the building. If uncorrected, fuel spilling out of the back

of the burner tube could cause a fire or explosion. To prevent fuel gas from spilling from the back

of the burners, check the burner ports at least annually and clean if necessary.

FIGURE 3 - View of

Control Compartment

with Access Panel and

All Sections of the

Burner Cover Removed

(Wires and tubing are not

illustrated.)

Burner

Rack

Screws

Manifold

Screws

Venter

Gas

Valve

Burner

Rack

Screws

Manifold

Screws

Control

Panel

Flue Wrapper

S

Instructions for Burner Rack Removal (See FIGURE 3.)

Instructions:

1) Locate the 1/8” FPT INLET pressure tap on the combination valve (FIGURE 2).