3 service procedures (cont'd), 4 troubleshooting, Lights – Reznor CAUA Users Manual User Manual

Page 14

Form O-CAUA, Page 14

3.0 SERVICE - Control Location, Operation, and Service (cont'd)

3.3 Service Procedures (cont'd)

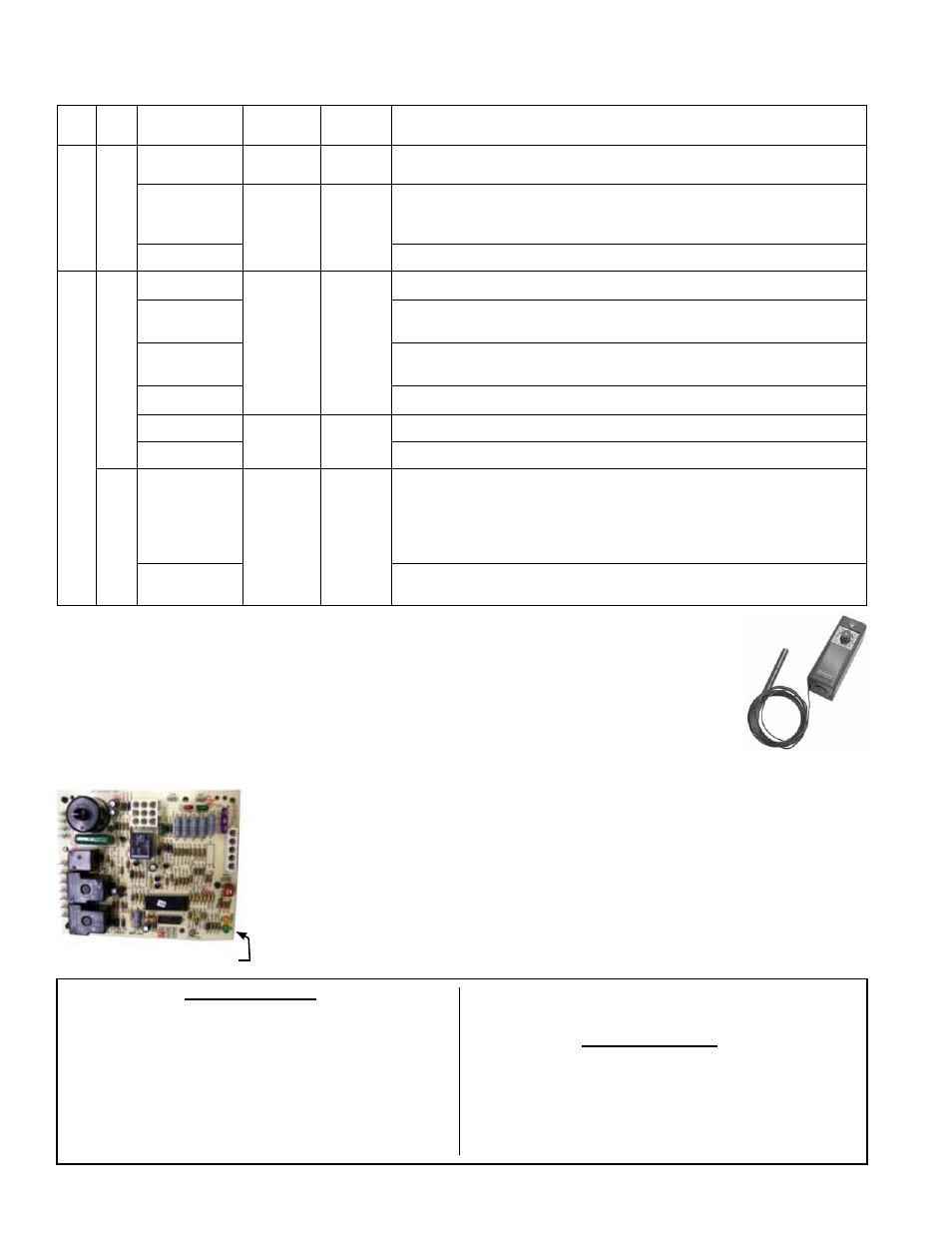

Mixing

Box

Option

Motor

Option

Control Option on

W.D.

Description

Operating

Mode

Application

GA1,

GA2,

GA3,

GA4,

GA5,

GA6,

GA7,

GA8,

and

GA9

GB2

None

2-Position

Damper Motor

Heating only

or Heating

and Cooling

When the unit is operating, the outside air damper is open.

GC3C

2-Position

Damper Motor

with 2-Position

Enthalpy

Control

Cooling only

To minimize cooling energy consumption and equipment cycling, when the sensor detects a low

enthalpy (heat content in a lb of air) in the outside air, the control will open the outside air damper.

When the control senses a high enthalpy in the outside air, the control will close the outside air

damper. Factory setpoint for opening the outside air damper is 75°F/40% humidity.

GC3C and GC4

Same as above (GC3C only) plus a delay based on return air temperature. Control delays the

opening of the outside air damper to provide faster cool down of the supply air.

GA4,

GA5,

GA6,

GA7,

GA8,

and

GA9

GB3

GC1A or GC1B

Modulating

Damper Motor

with Manual

Potentiometer

Mounted in

the Mixing

Box (GC1A)

or Remote

(GC1B)

Heating only

or Heating

and Cooling

To control mixture of inlet air, manually set the potentiometer to the desired minimum position of

the outside air damper. (See IMPORTANT NOTE left.)

GC1A or GC1B with

GC3A

Same as above (GC1A or GC1B only) plus in heating mode the dampers are modulated in

response to a control sensing the mixed inlet air temperature. The adjustable control has a range

of 0-100°F; factory setpoint is 35°F. (See IMPORTANT NOTE left.)

GC1A or GC1B with

GC4

Same as above (GC1A or GC1B only) plus a delay based on return air temperature. Control

delays the opening of the outside air damper to provide faster cool down (cooling mode) or warm

up (heating mode) of the supply air.

GC1A or GC1B with

both GC3A and GC4

Includes all of the control functions listed in this section - a potentiometer (GC1A or GC1B) with

both the mixed air controller (GC3A) and the delay (GC4).

GC3A

Modulating

Damper Motor

with Mixed Air

Controller

Heating only

Dampers are modulated in response to a control sensing the mixed inlet air temperature. The

adjustable control has a range of 0-100°F; factory setpoint is 35°F. (See IMPORTANT NOTE left.)

GC3A and GC4

Above plus a delay based on return air temperature. Control delays the opening of the outside air

damper to provide faster warm up of the supply air.

GB4

GC3B

Modulating

Damper Motor

with a Logic

Module and

Dual Setpoint

Modulating

Enthalpy

Control

Cooling and

Heating

In cooling mode, damper modulation is controlled by a modulating enthalpy control. With one

sensor measuring the enthalpy of the outside air and another sensing the return air, dampers

will modulate in response to the control to maintain the most economic mix in the inlet air

(normally set to maintain between 50-56°F). With two enthalpy setpoints, damper operation can

be interlocked with a time clock or other device to provide different mix depending on occupancy

or other determining factor. In the heating mode, damper modulation is controlled by a mixed air

temperature sensor. (See IMPORTANT NOTE left.)

GC3B and GC4

Above (GC3B only) plus a delay based on return air temperature. Control delays the opening of

the outside air damper to provide faster cool down (cooling mode) or warm up (heating mode) of

the supply air.

3.3.11 Ductstat used in

Makeup Air Gas Control

Option AG3 (available

only with Option AD4)

Function: The ductstat with attached capillary tube

senses the discharge air temperature and operates the

two stage valve to maintain the temperature within a

fixed differential of 2-1/2°F. Adjustable factory setting is

70°F.

Service: If the ductstat does not operate properly,

replace with an identical control.

Ductstat,

P/N 41700

The integrated circuit board monitors the operation of the heater and includes two

LED signal lights that indicate normal operation and various abnormal conditions. If

the heater fails to operate properly, check this signal to determine the cause and/or to

eliminate certain causes. Open the door panel to view the LED lights.

Do not attempt to repair the DSI integrated control module; the only field replaceable

component is the fuse.

Control Status - Green LED Codes

Steady ON .... Normal Operation, No call for heat

Fast Flash ..... Normal Operation, Call for heat

1 Flash .......... System Lockout, Failed to detect or sus-

tain flame

2 Flashes ...... Pressure Switch Did Not Close within 30

Seconds of Venter Motor

3 Flashes ...... High Limit Switch Open

4 Flashes ...... Pressure switch is closed before venter

motor is energized

Steady OFF .. Blown Fuse, No Power, or Defective

Board

Flame Status - Yellow LED Codes

Steady ON .... Flame is sensed

Slow Flash .... Weak flame (current below 1.0 micro-

amps ±50%)

Fast Flash ..... Undesired Flame (valve open and no call

for heat)

Lights

3.4 Troubleshooting

Check the Ignition Control Module - The integrated ignition control module monitors

the operation of the heater and includes LED signals that indicate normal operation

and various abnormal conditions. If the heater fails to operate properly, check this sig-

nal to determine the cause and/or to eliminate certain causes.