Warning, Caution, Air conditioner maintenance – Reznor JS4BD (1ph) Unit Installation Manual User Manual

Page 6

6

noteS:

• Factory installed modules have different thermostat

demand signal wiring. Always follow manufacturer

wiring instructions when replacing the module.

• After the thermostat demand signal is connected, verify

that 24 VAC across Y & C when demand is present.

Interpreting the Diagnostic LED’s

When an abnormal system condition occurs, the Comfort

Alert

TM

module displays the appropriate ALERT and/or

TRIP LED will flash a number of times consecutively,

pause and then repeat the process. To identify a Flash

Code number, count the number of consecutive flashes.

Each time the module powers up, the last ALERT Flash

Code that occurred prior to shut down is displayed for

one minute. The module will continue to display the LED

until the condition returns to normal or if 24 VAC power

is removed from the module. See Table 10 (page 17) for

flash code identification or Table 11 (page 18) for module

wiring troubleshooting.

LED Description

• POWER LED (Green): indicates voltage is present at

the power connection of the module.

• ALERT LED (Yellow): communicates an abnormal

system condition through a unique flash code.

note: The ALERT LED will flash consecutively,

pause and then repeat the process. The number of

consecutive flashes, referred to as the Flash Code,

correlates to a particular abnormal condition. Detailed

descriptions of these ALERT Flash Codes are listed

in Tables 10 & 11.

• TRIP LED (Red): indicates a demand signal is received

from the thermostat, but current to the compressor is

not detected by the module. The TRIP LED typically

indicates if the compressor protector is open or the

compressor has no power.

The scroll compressor’s r (run), c (common), and S

(start) wires are routed through the holes in the Comfort

Alert

TM

module marked r, c, & S.

note: The common

wire does not need to be routed through the module for

it to operate.

thermostat connections

• Thermostat connections should be made in accordance

with the instructions supplied with the thermostat and

the indoor equipment.

• The outdoor unit is designed to operate from a 24 VAC

Class II control circuit. The control circuit wiring must

comply with the current provisions of the NEC (ANSI/

NFPA 70) and with applicable local codes having

jurisdiction.

• The low voltage wires must be properly connected to

the units low voltage terminal block. Recommended

wire gauge and wire lengths for typical thermostat

connections are listed in Table 2.

• The thermostat should be mounted about 5 feet

above the floor on an inside wall. DO NOT install the

thermostat on an outside wall or any other location

where its operation may be adversely affected by radiant

heat from fireplaces, sunlight, or lighting fixtures, and

convective heat from warm air registers or electrical

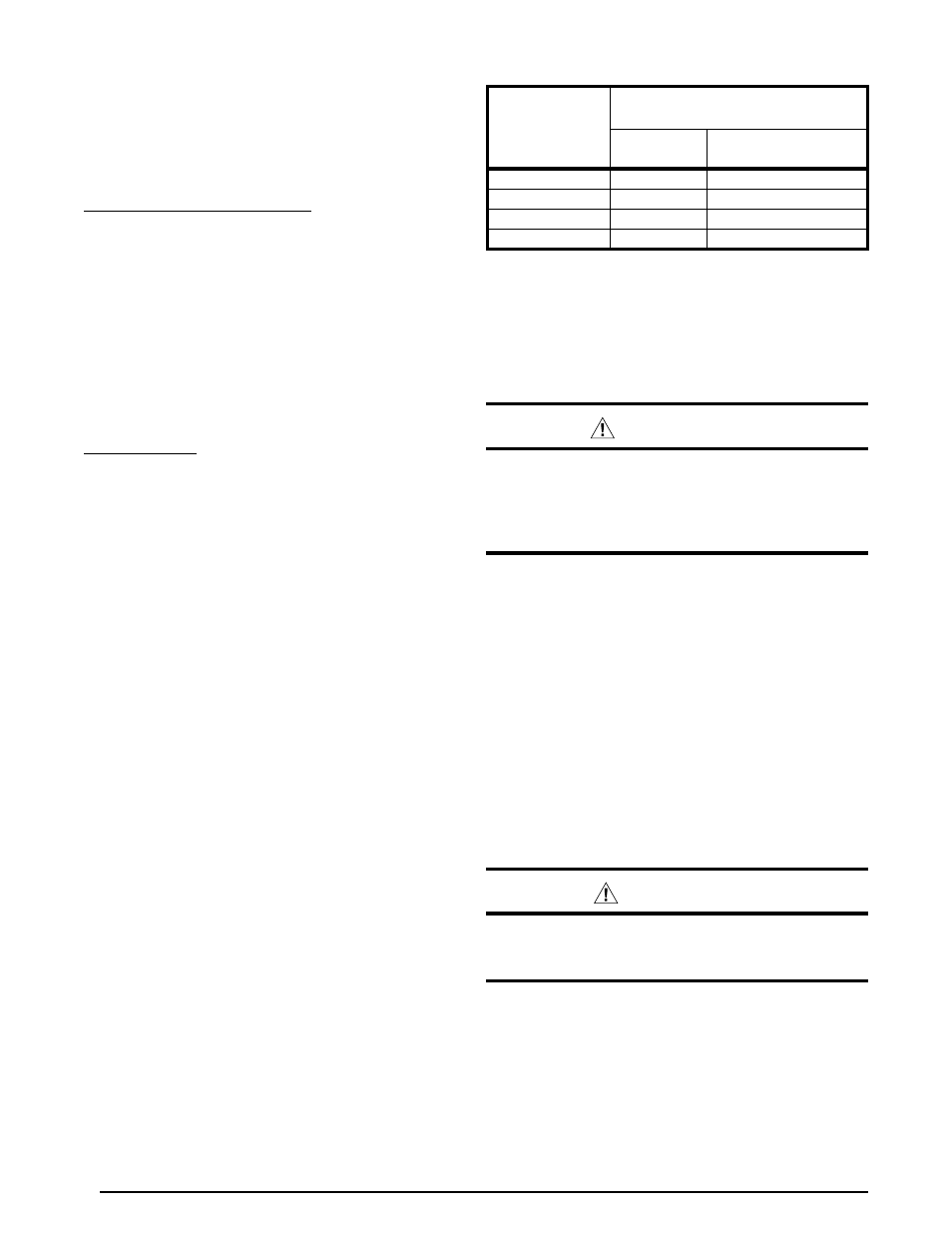

table 2. thermostat Wire gauge

thermostat

Wire gauge

recommended t-Stat Wire

unit to t-Stat (length in ft)

2-Wire

(heating)

5-Wire

(heating/cooling)

24

55

25

22

90

45

20

140

70

18

225

110

air conditioner maintenance

Warning:

to prevent electrical shock, personal injury, or

death, disconnect all electrical power to the unit

before performing any maintenance or service.

the unit may have more than one electrical

supply.

Proper maintenance is important to achieve optimum

performance from the air conditioner. The ability to properly

perform maintenance on this equipment requires certain

mechanical skills and tools. If you do not possess these

skills, contact your dealer for maintenance. Consult your

local dealer about the availability of maintenance contracts.

Routine maintenance should include the following:

• Inspect and clean or replace air filters at the beginning

of each heating and cooling season, or more frequently

if required.

• Inspect the condensate drain and outdoor coil at the

beginning of each cooling season. Remove any debris.

Clean the outdoor coil and louvers as necessary using

a mild detergent and water. Rinse thoroughly with

water.

• Inspect the electrical connections for tightness at the

beginning of each heating and cooling season. Service

as necessary.

caution:

the unit should never be operated without a

filter in the return air system. replace disposable

filters with the same type and size.

• Do not attempt to add additional oil to motors un

-

equipped with oil tubes. The compressor is hermetically

sealed at the factory and does not require lubrication.

appliances. Refer to the thermostat manufacturer’s

instruction sheet for detailed mounting and installation

information.