Horizontal vent terminal clearances, Figure 8b - horizontal vent terminal – Reznor X Option - Option - Installation - Power Venter User Manual

Page 9

Form I-X Venter, P/N 136958R1, Page 9

Structure

Min Clearances for Vent Termination

Location (all directions unless specified)

Forced air inlet within 10 ft (3.1m) 3 ft (0.9m) above

Combustion air inlet of another appliance 6 ft (1.8m)

Door, window, or gravity air inlet 4 ft (1.2m) horizontally

(any building opening)

4 ft (1.2m) below

1 ft (30cm) above

Electric meter, gas meter * and relief 4 ft (1.2m) horizontally

equipment

Gas regulator *

3 ft (0.9m)

Adjoining building or parapet

6 ft (1.8m)

Adjacent public walkways

7 ft (2.1m) above

Grade (ground level)

7 ft (2.1m) above

*Do not terminate the vent directly above a gas meter or service regulator.

6. Test Venter Operation

Turn on the electric and the gas. Following the lighting

instructions, light the heater. Test the unit for proper vent-

ing. With the building at the maximum negative pressure,

operate the heater at the normal input. Note and check the

flow direction at the relief opening of the drafthood. Room air

should be flowing into the relief opening.

DANGER: Do not put a heater into service

that does not properly exhaust flue gases to

the outside atmosphere. See Hazard Levels,

page 1.

Venter installation is complete.

Keep this booklet for future

reference. Replacement parts are on page 8.

DANGER: The gas burner in this gas-fired equip-

ment is designed and equipped to provide safe

and economically controlled complete combus-

tion. However, if the installation does not permit

the burner to receive the proper supply of combus-

tion air, complete combustion may not occur. The

result is incomplete combustion which produces

carbon monoxide, a poisonous gas that can cause

death. Safe operation of indirect-fired gas burning

equipment requires a properly operating vent sys-

tem which vents all flue products to the outside at-

mosphere. FAILURE TO PROVIDE PROPER VENT-

ING WILL RESULT IN A HEALTH HAZARD WHICH

COULD CAUSE SERIOUS PERSONAL INJURY OR

DEATH.

Always comply with the combustion air require-

ments in the installation codes and instructions.

Combustion air at the burner should be regulated

only by manufacturer-provided equipment. NEVER

RESTRICT OR OTHERWISE ALTER THE SUPPLY

OF COMBUSTION AIR TO ANY HEATER. Indoor

units installed in a confined space must be sup-

plied with air for combustion as required by Code

and in the heater installation manual. MAINTAIN

THE VENT SYSTEM IN STRUCTURALLY SOUND

AND PROPERLY OPERATING CONDITION.

FOR YOUR SAFETY

WARNING: The use and storage of

gasoline or other flammable vapors

and liquids in open containers in the

vicinity of this appliance is hazardous.

If you smell gas:

1. Open windows.

2. Don't touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

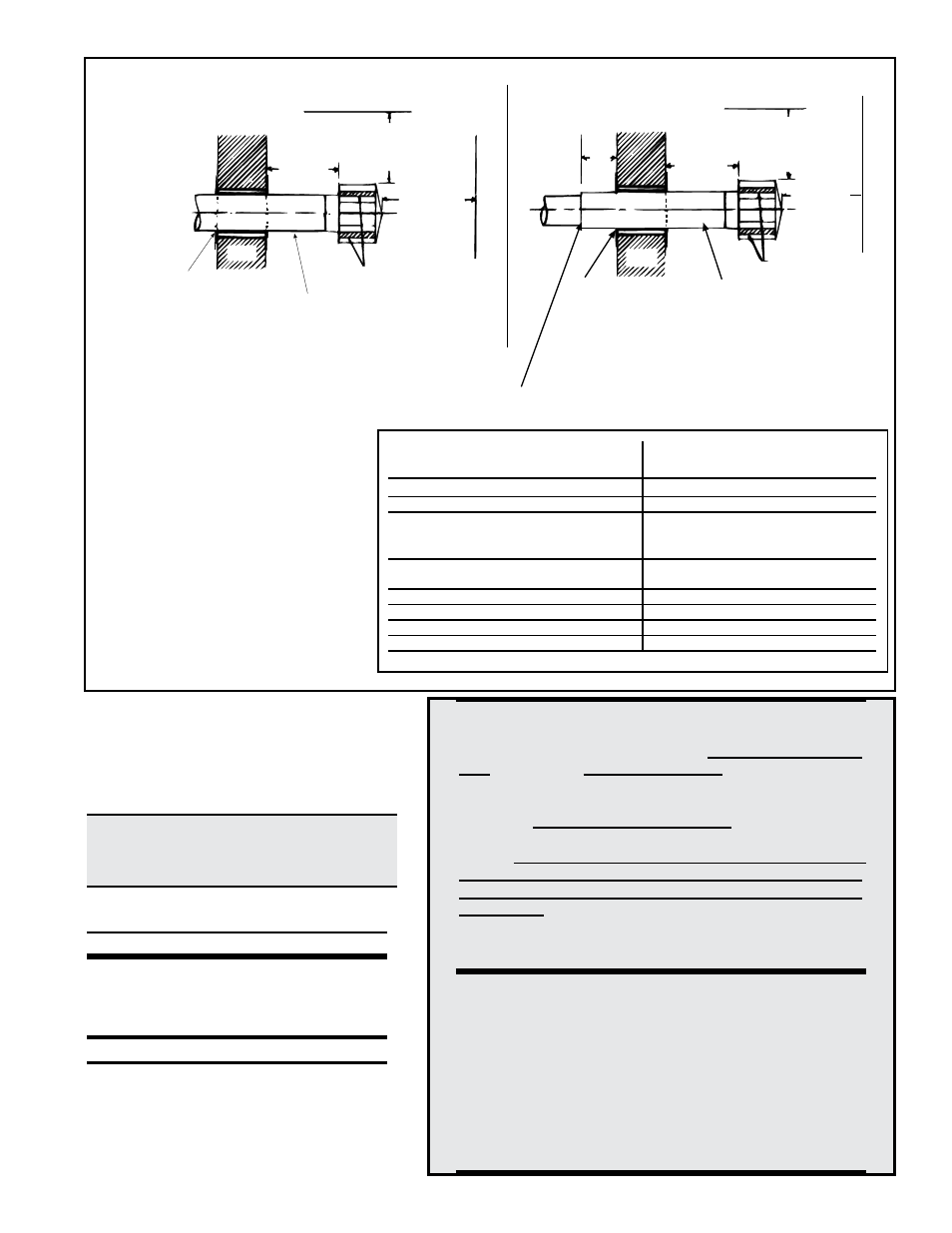

Roof or Building Overhang

3 (1M) minimum

18

(457mm)

minimum

6 (2M)

minimum

Wall

Parapet or

Adjoining Building

Approved clearance

thimble for single-wall

vent pipe is required

when flue pipe extends

through combustible

materials.

Note position of vent

cap openings.

Pitch flue pipe down toward outlet

1/4 per foot for condensate drainage.

(NOTE: Applies to entire horizontal

vent run.)

Adjoining Building

Parapet or

Roof or Building Overhang

6 (2M)

minimum

3 (1M) minimum

18

(457mm)

minimum

Wall

Approved clearance

thimble for single-wall

vent pipe is required

when flue pipe extends

through combustible

materials. Follow

the requirements

of the double-wall

pipe manufacturer.

Pitch flue pipe down toward

outlet 1/4 per foot for con-

densate drainage.

(NOTE: Applies to entire

horizontal vent run.)

Note position of

vent cap openings.

6 (152mm) minimum

Follow instructions on page 6 to join single

and double-wall pipe and to seal the connection.

Single-Wall Vent Run and Double-Wall Terminal End

Single-Wall Vent Run and

Single-Wall Terminal End

Horizontal Vent Terminal

Clearances

A vent cap is required. Maintain a clear-

ance of 18" from the wall to the vent ter-

minal cap for stability under wind condi-

tions. The location of the termination of

the horizontal vent system must be in

accordance with National Fuel Gas Code

Z223.1. Required minimum clearances

are listed on the right.

Products of combustion can cause dis-

coloration of some building finishes

and deterioration of masonry materials.

Applying a clear silicone sealant that is

normally used to protect concrete drive-

ways can protect masonry materials.

If discoloration is an esthetic problem,

relocate the vent or install a vertical vent.

If the vent terminal is to be installed near

ground level, position it at least six inches

above maximum anticipated snow depth.

Figure 8B - Horizontal Vent Terminal