Reznor X Option - Option - Installation - Power Venter User Manual

Page 7

Form I-X Venter, P/N 136958R1, Page 7

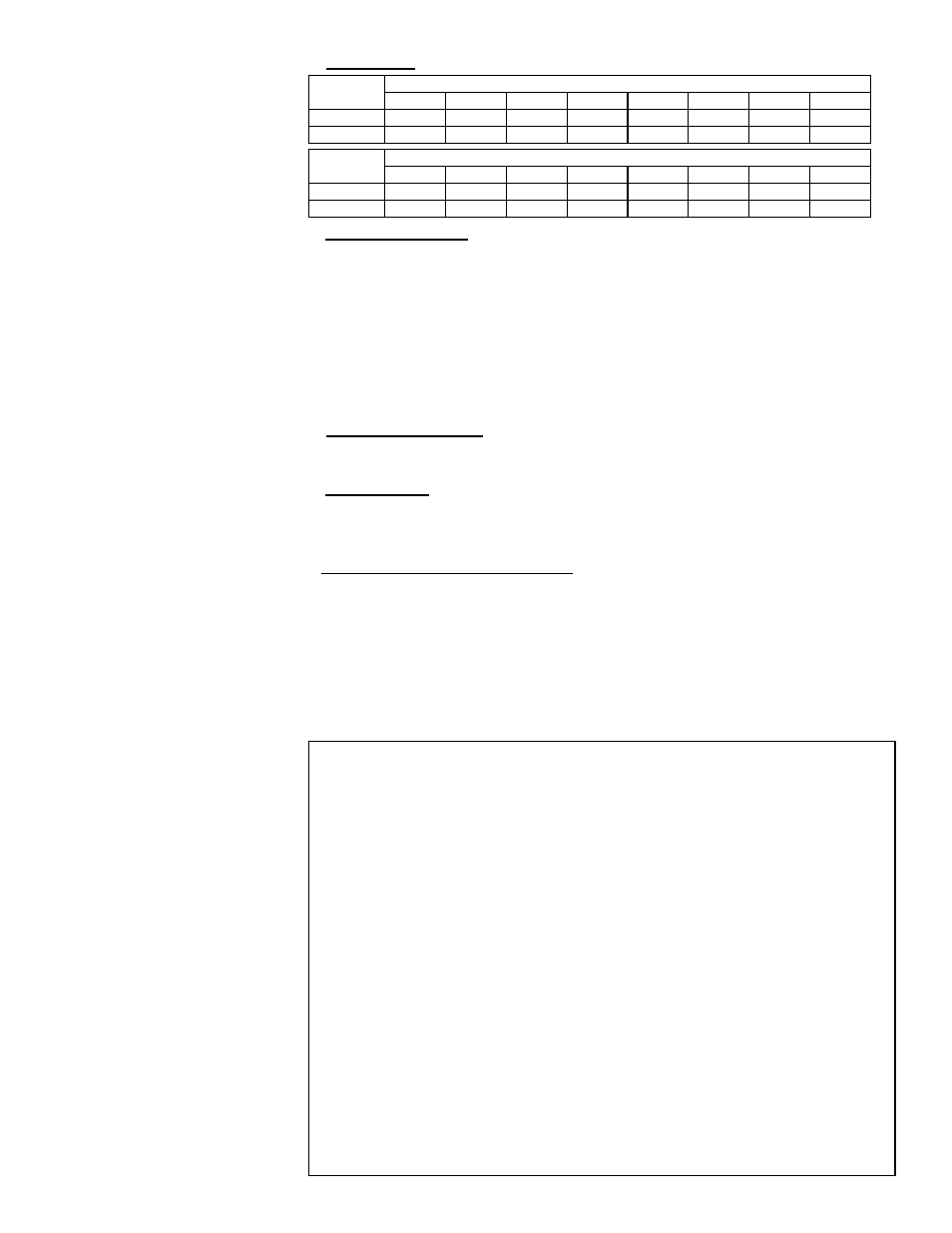

*Reduce the vent pipe

lengths as follows for each

item: 45

o

Elbow - 7ft (2M);

90

o

Elbow - 15ft (4.5M);

Vent Cap - 10 ft (3M).

** If the venter outlet is 4"

(102mm), connect a taper-

type "enlarger" to the ven-

ter outlet when installing

6" (152mm) vent pipe.

b. Vent Length - Minimum vent length is 5 feet.

Vent

Diameter

Maximum Length* (ft) by Heater Size

30-150

175

200

225

250

300

350

400

4"

100

75

50

35

30

15

--

--

6"

--

--

--

--

100**

100**

100

92

Vent

Diameter

Maximum Length* (M) by Heater Size

30-150

175

200

225

250

300

350

400

102mm

30

23

15

11

9

4.5

--

--

152mm

--

--

--

--

30**

30**

30

28

c. Vent System Joints - Vent system joints depend on the installation and the type of

pipe being used.

If installed as a Category III heater (required if more than half of the equivalent

length of the vent system is horizontal), use

vent pipe specifically approved for

Category III vent systems. Follow the pipe manufacturer's instructions for proper

sealing.

If installed with a Category I vent system (allowed only if at least half of the

equivalent length of the vent system is vertical), use at least two non-corrosive

screws per vent pipe joint on single-wall pipe or follow the pipe manufacturer's

instructions for joining double-wall pipe.

d. Vent System Support - Lateral runs should be supported every six feet using a

non-combustible material, such as strap steel or chain. Do not rely on the heater

for support of either horizontal or vertical vent pipe.

e. Condensation - Any length of single-wall vent pipe exposed to cold air or run

through an unheated area or an area with an ambient temperature of 45°F or

less must be insulated along its entire length with a minimum of 1/2" foil-faced

fiberglass, 1-1/2# density insulation.

f. Vent Terminal (Pipe and Vent Cap) - The vent cap must be the same size as the

vent pipe (vent pipe is either 4" or 6" diameter). For optimum stability under wind

conditions, use a Reznor

®

vent cap.

See the illustrations in

FIGURES 7A and 7B for requirements of vertical and

horizontal vent termination. The vent terminal pipe may be either single-wall or

double-wall (Type B). (Check local codes for double-wall terminal requirement.) If

double-wall pipe is used in the vent terminal with a single-wall vent run, follow the

instructions below to attach the vent cap and to connect the double-wall pipe to the

single-wall vent pipe run.

Instructions to attach VENT CAP to DOUBLE WALL (Type B) VENT TERMINAL

PIPE

Look for the "flow" arrow on the vent pipe. Attach the vent cap to the "exhaust" end

of the double wall pipe.

1) Slide the vent cap inside the pipe.

2) Drill a hole through the pipe and the vent cap. (Hole should be slightly smaller

than the sheet metal screw being used.) Using a 3/4" long sheet metal screw,

attach the cap to the pipe.

3) Repeat Step 2) drilling and inserting two additional screws evenly spaced (120°

apart) around the pipe.

Instructions to connect a SINGLE WALL VENT RUN to a DOUBLE WALL (Type

B) VENT TERMINAL PIPE:

1) Slide the single wall pipe inside the inner wall of the double-wall terminal pipe.

2) Drill a hole through both walls of the double wall pipe and the single wall pipe.

(Hole should be slightly smaller than the sheet metal screws being used.)

Using a 3/4" long sheet metal screw, attach the two pieces of pipe. Do not

overtighten.

3) Repeat Step 2) drilling and inserting two additional screws evenly spaced (120

o

apart) around the pipe.

4) To seal the annular opening (the gap between the single and double wall pipe),

run a large bead of silicone sealant in the opening. The bead of sealant must

be large enough to seal the opening, but it is not necessary to fill the full vol-

ume of the annular area.