Gt-px, Performance correction factors – Carrier GT-S User Manual

Page 20

GT-PX

18

Carrier Indoor & Outdoor Split Geothermal Heat Pumps - Rev.: 08/10/05

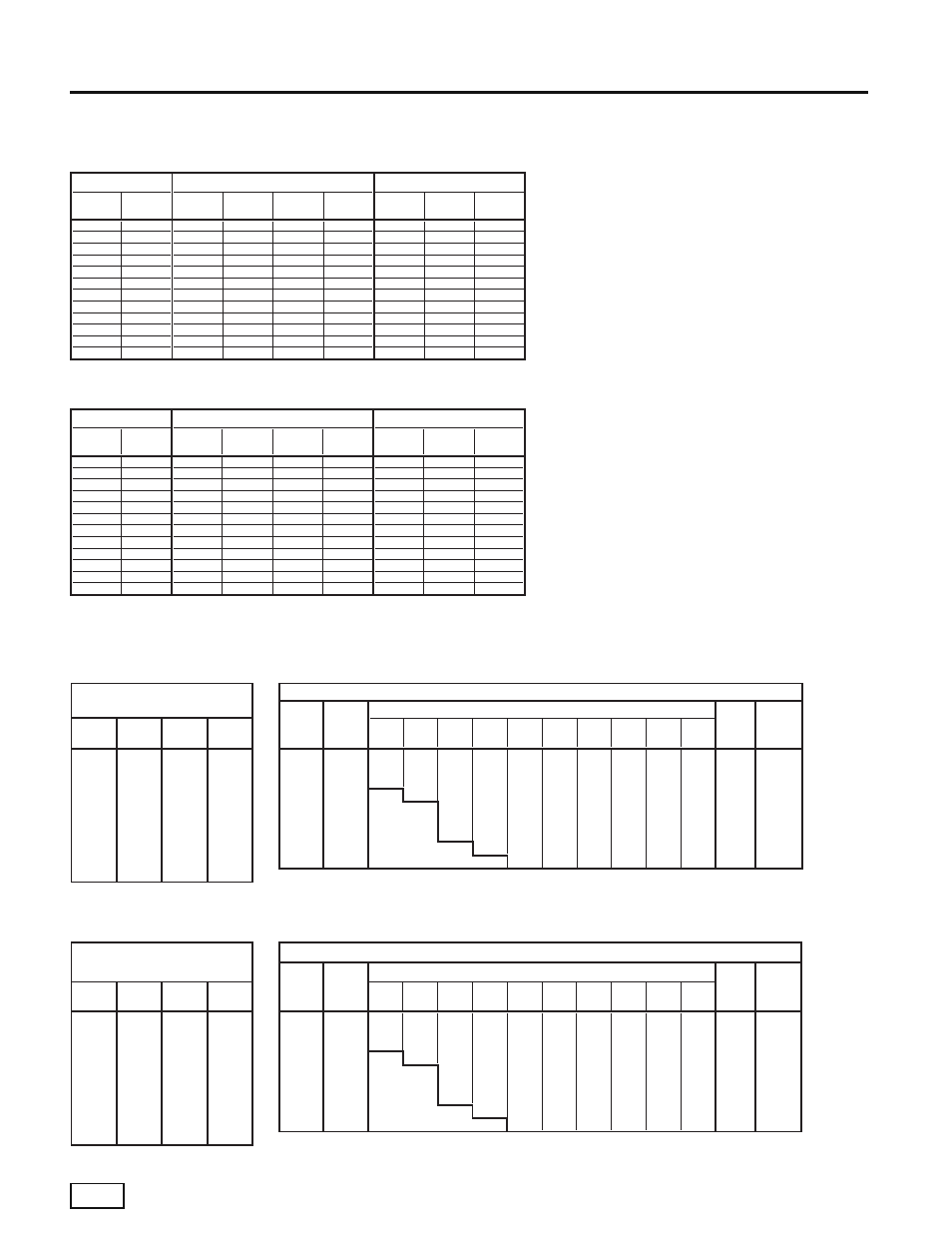

Performance Correction Factors

Full Load Heating Corrections

Full Load Cooling Corrections

Sens Clg Cap Multipliers- Entering DB

°F

Ent Air DB

°F

Htg Cap

Power

Heat of

Ext

Ent Air

WB

°

F

Total Clg

Cap

60

65

70

75

80

80.6

85

90

95

100

Power

Heat of

Rej

40

1.052

0.779

1.120

45

0.832

1.346

1.461

1.603

0.946

0.853

45

1.043

0.808

1.102

50

0.850

1.004

1.174

1.357

0.953

0.870

50

1.035

0.841

1.084

55

0.880

0.694

0.902

1.115

1.331

0.964

0.896

55

1.027

0.877

1.065

60

0.922

0.646

0.875

1.103

1.329

1.356

0.977

0.932

60

1.019

0.915

1.045

65

0.975

0.639

0.869

1.096

1.123

1.320

0.993

0.979

65

1.010

0.957

1.023

66.2

0.990

0.582

0.812

1.039

1.066

1.262

1.482

0.997

0.991

68

1.004

0.982

1.010

67

1.000

0.545

0.774

1.000

1.027

1.223

1.444

1.000

1.000

70

1.000

1.000

1.000

70

1.040

0.630

0.853

0.880

1.075

1.297

1.517

1.011

1.035

75

0.989

1.045

0.974

75

1.117

0.601

0.627

0.821

1.046

1.275

1.510

1.033

1.101

80

0.976

1.093

0.946

Rev.: 03/29/04

*

Sensible capacity equals total capacity (no latent capacity) at conditions shown as "

*

"

ARI/ISO/ASHRAE 13256-1 uses entering air conditions of Clg- 80.6

°F DB/66.2°F WB and Htg- 68°F DB/59°F WB

TT Full Load Entering Air Corrections

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

TT Full Load Air Flow Corrections

Airflow

Cooling

Heating

CFM Per

Ton of Clg

% of

Nominal

Total Cap

Sens Cap

Power

Heat of Rej

Htg Cap

Power

Heat of Ext

240

60

0.925

0.788

0.913

0.922

0.946

1.153

0.896

275

69

0.946

0.829

0.926

0.942

0.959

1.107

0.924

300

75

0.960

0.861

0.937

0.955

0.969

1.078

0.942

325

81

0.972

0.895

0.950

0.968

0.977

1.053

0.959

350

88

0.983

0.930

0.965

0.979

0.985

1.032

0.974

375

94

0.992

0.965

0.982

0.990

0.993

1.014

0.988

400

100

1.000

1.000

1.000

1.000

1.000

1.000

1.000

425

106

1.007

1.033

1.020

1.009

1.006

0.989

1.011

450

113

1.012

1.064

1.042

1.018

1.012

0.982

1.019

475

119

1.016

1.092

1.066

1.025

1.018

0.979

1.027

500

125

1.018

1.116

1.091

1.032

1.022

0.977

1.033

520

130

1.019

1.132

1.112

1.037

1.026

0.975

1.038

Part Load Heating Corrections

Part Load Cooling Corrections

Sens Clg Cap Multipliers- Entering DB

°F

Ent Air DB

°F

Htg Cap

Power

Heat of

Ext

Ent Air

WB

°

F

Total Clg

Cap

60

65

70

75

80

80.6

85

90

95

100

Power

Heat of

Rej

40

1.084

0.732

1.161

45

0.876

1.286

1.302

1.389

0.981

0.895

45

1.073

0.764

1.140

50

0.883

1.002

1.099

1.241

0.985

0.901

50

1.060

0.802

1.117

55

0.903

0.706

0.871

1.060

1.271

0.989

0.918

55

1.046

0.846

1.090

60

0.935

0.617

0.844

1.079

1.319

1.349

0.993

0.945

60

1.031

0.893

1.061

65

0.979

0.595

0.849

1.098

1.128

1.342

0.998

0.982

65

1.016

0.945

1.031

66.2

0.991

0.531

0.789

1.040

1.070

1.284

1.522

0.999

0.993

68

1.006

0.978

1.013

67

1.000

0.486

0.747

1.000

1.030

1.245

1.481

1.000

1.000

70

1.000

1.000

1.000

70

1.035

0.583

0.842

0.873

1.090

1.327

1.552

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

1.003

1.030

75

0.984

1.058

0.968

75

1.105

0.552

0.584

0.811

1.057

1.290

1.510

1.008

1.088

80

0.968

1.117

0.936

Rev.: 03/29/04

*

Sensible capacity equals total capacity (no latent capacity) at conditions shown as "

*

"

ARI/ISO/ASHRAE 13256-1 uses entering air conditions of Clg- 80.6

°F DB/66.2°F WB and Htg- 68°F DB/59°F WB

TT Part Load Entering Air Corrections

TT Part Load Air Flow Corrections

Airflow

Cooling

Heating

CFM Per

Ton of Clg

% of

Nominal

Total Cap

Sens Cap

Power

Heat of Rej

Htg Cap

Power

Heat of Ext

240

60

0.920

0.781

0.959

0.927

0.946

1.241

0.881

275

69

0.942

0.832

0.964

0.946

0.960

1.163

0.915

300

75

0.956

0.867

0.969

0.959

0.969

1.115

0.937

325

81

0.969

0.901

0.975

0.970

0.978

1.076

0.956

350

88

0.981

0.934

0.982

0.981

0.986

1.043

0.973

375

94

0.991

0.967

0.990

0.991

0.993

1.018

0.988

400

100

1.000

1.000

1.000

1.000

1.000

1.000

1.000

425

106

1.007

1.033

1.011

1.008

1.006

0.990

1.010

450

113

1.013

1.065

1.023

1.015

1.012

0.986

1.017

475

119

1.018

1.098

1.036

1.021

1.017

0.983

1.024

500

125

1.021

1.131

1.051

1.026

1.021

0.981

1.030

520

130

1.023

1.159

1.063

1.030

1.024

0.979

1.034

Entering Air Correction Factors

Airfl ow Correction Factors