Instruction manual hk-d, Sauter gmbh – KERN & SOHN HK-D User Manual

Page 14

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: [email protected]

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

Instruction Manual

HK-D

HK-D-BA-e-1311

14

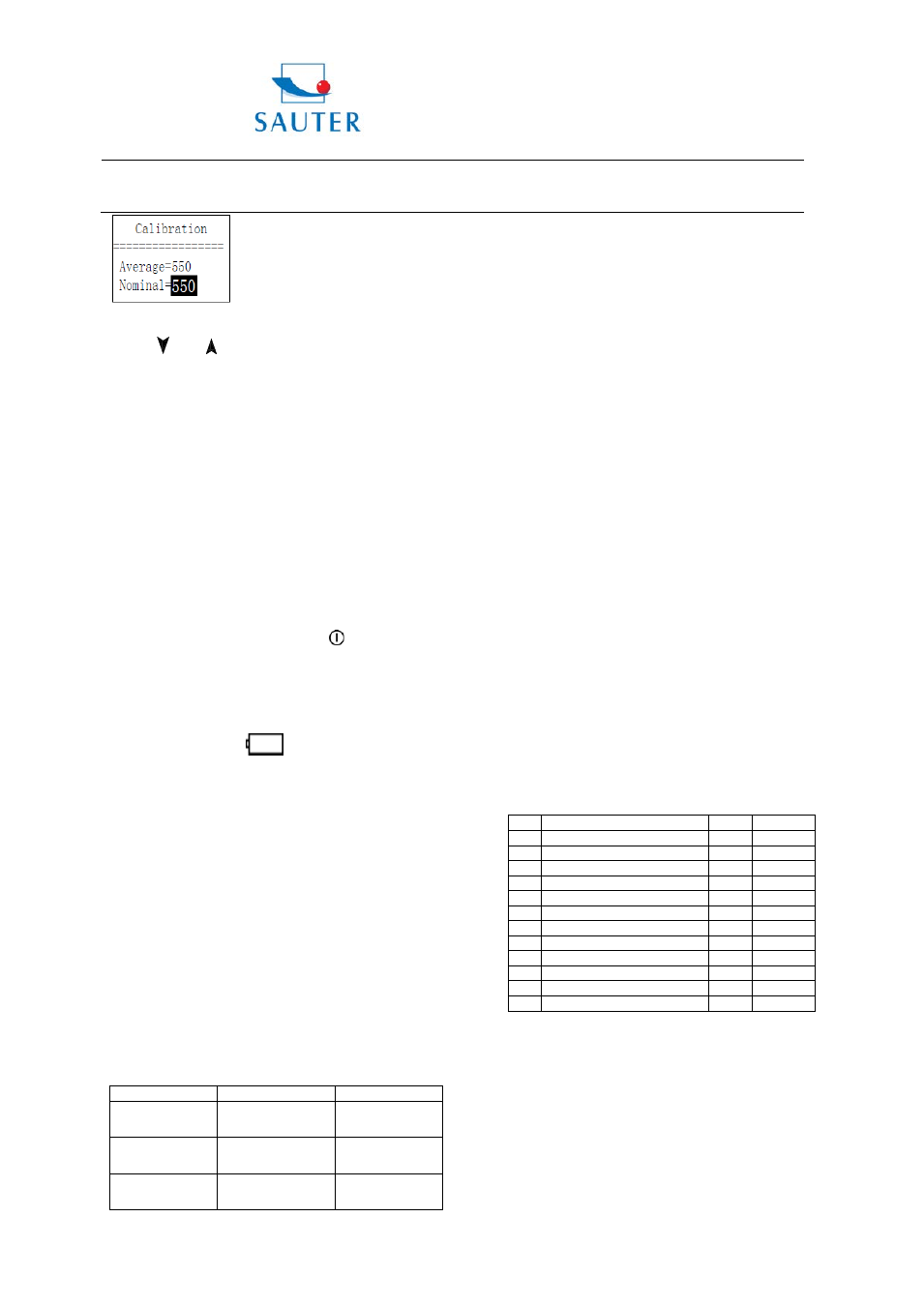

Average value will be showed after measuring.

Press 【

】 or 【

】 】 key to input nominal value.

Press 【 ENTER】 key to finish calibration.

Press 【 ESC】 key to cancel calibration.

Calibration range is ±15HL.

6.12 Back light

The LCD display is equipped with a Led Back Light, which

supplied for easily use in dark light conditions. The Back

Light can be turned on or turned off by pressing 【

】 at

any time when the tester is in operation.

6.13 Turn off the power automatically

Auto turn off function is supplied to save the energy of

battery.

If neither measurement nor any key operation is performed

within 5 minutes, the tester will turn off automatically, a

flash showing for 20 seconds on the LCD screen prior to

switch off. At this time, any key except

can be pressed

to stop the flash of LCD screen, and cancel the turn off

operation.

In case of too low battery voltage, “Battery Empty!” will be

displayed and turn off automatically.

6.14 Battery replacement

Battery symbol will flash

if battery capacity runs out.

At this point, User can replace the damaged battery

according to the following procedures.

Turn off the Power of main unit.

Unscrew the screw. Remove the battery cover, take out

used batteries.

Install the new batteries in their place (pay attention to

orientation of batteries, take caution not to connect the

anode and cathode inversely).

Put back the battery cover, then turn on the power to

check if the tester is in normal operation or not.

6.15 The connection of data communication cable

The small 4-pin plug which located on the end of

communication cable should be inserted in the RS232

socket on the left side of main unit, and D type 9-pin

RS232 port 9-pin port should be inserted in PC

communication or the serial port printer case.

7 Trouble shooting

Failure

Cause

Solution

Failure in

starting

Battery empty

Replace battery

No measuring

value

Sensor

cable

open circuit

Replace Probe

cable

Value

is

inaccurate

Calibration data

lose

over again

Calibration

8 Maintenance

8.1 Impact device

After using the impact device for 1000-2000 times, use the

nylon brush, optional available, to clean the guide tube and

the impact body of the impact device. To clean the guide

tube, unscrew the support ring and then take out the

impact body, spiral the nylon brush in the counter-clock

direction into the guide tube. When the brush reaches the

bottom, draw it out. Repeat this action for 5 times and

mount the impact body and the support ring.

Remember to release the impact body after use.

Any lubricating agent is absolutely banned to use inside

the impact device.

8.2 Standard maintenance procedures

If the error is

> 2HRC when using standard Rockwell

hardness block to test, maybe the test tip is disabled.

Changing the test tip or impact body should be considered.

If other abnormal phenomena occur, user should not

disassemble or adjust any part which used for fixing. You

can return the hardness tester to the service department of

our company.

9. Notice of Transportation and Storage.

The tester should be stored in room temperature, away

from vibration, strong magnetic field, corrosive medium,

dampness and dust.

10. Non-warranty parts

1 Sheath of Main unit 2 Panel 3 Impact body

4 Support ring 5 Sensor cable 6. Battery.

Leeb Hardness Tester

Packing List

No

Appellation

Num

1

Main unit

1

2

D type impact device

1

3

Small supporting ring

1

6

Instruction Manual

1

7

Carrying case

1

8

Screwdriver

1

9

10

Communication cable

Optional

11

DataView Software ATC 01

Optional

12

AA battery

Optional

13

Printer

Optional

14

Printer cable

Optional