KERN & SOHN TVO 500N300 User Manual

Instruction manual tvo, Sauter gmbh

Sauter GmbH

Tieringerstr. 11-15

D-72336 Balingen

E-Mail: [email protected]

Tel: +49-[0]7433- 9976-174

Fax: +49-[0]7433-9976-285

Internet: www. sauter.eu

Instruction Manual

TVO

TVO-BA-e-1112

1

ELECTRIC VERTICAL TEST STAND

TVO500N300

Table of contents

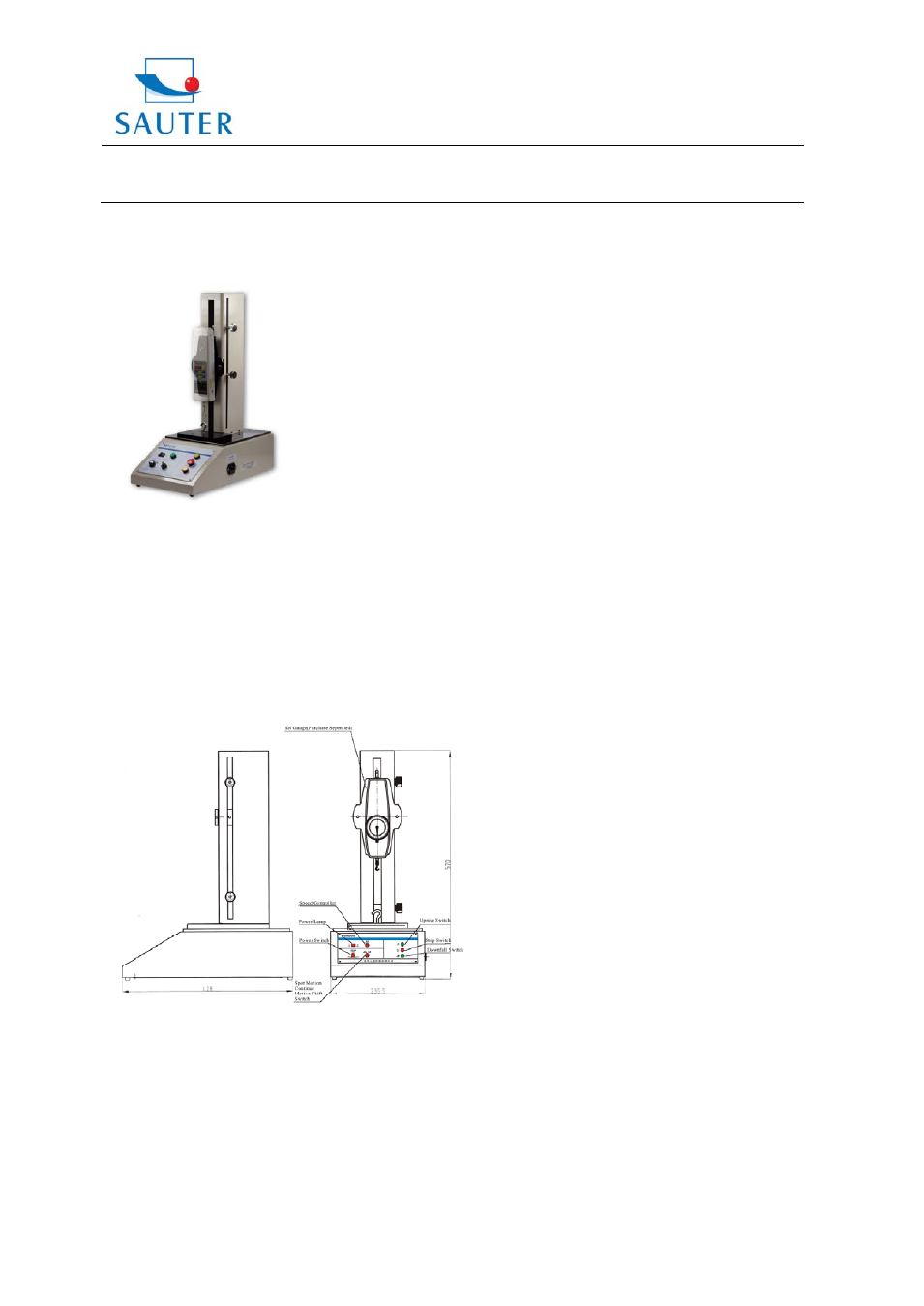

1. Construction

2. Function

3. Specification

4. Operation

5. Maintenance

6. Packing list

7. Declaration of Conformity

1.

Construction

2.

Function

The electrical vertical test stand TVO500N300 is applied in

tension and compression tests. It can be assembled with

push and pull gauges. The test stand is of good stability,

has got a wide application range and it is easy to operate.

Furthermore, it has the advantage of non-polar speed

adjustment, manual and automatic operation and auto

control of switch function. It is suitable in the field of rubber

& plastic products, light industry & textile, construction of

frame, complex material, wires & cables, automobile

components, engine and scientific research.

3.

Specification

Capacity 500N

Measuring stroke 300mm

Maximum measuring speed 500mm/min

Work voltage Single-phase 220V

Rate flow 1.5A

Fuse of main circuit 3A

Fuse of controlling circuit 0.5A

Working temperature 20± 10°C

Store & Delivery temperature -27°C up to +70°C

Relative Humidity 15% up to 80% RH

4.

Operation

Examine before operation!

A.

The retainer has to be locked, the power has to

be switched on by the power switch. The power

lamp will be flashing.

B.

The test stand has to be examined if there is any

abnormal sound with the test stand moving

without load.

Manual (automatic) test

A.

The manual/automatic switch to manual

operation position has to be turned on.

B.

The up/ down button on the stand has to be

pressed, then the stand will begin to work.

C. The button has to be loosened, then the test

stand will stop working.

Adjustment of test speed

The test speed is adjustable in the course of testing or

before the test.

The speed controller has to be turned to the required

speed.

5.

Maintenance

A. The environment has to be kept clean; liquid and metal

scraps have to be prevented from entering the engine box;

otherwise there is the risk of electric shocks or moving

components may be damaged.

B. The column and motion pedestal has to be kept clean of

lubricants.

C. Some lubricant has to be added to the drive stroke and

gear after some times of usage.

D. The test stand has to be kept away from dust and

moisture in case if it isn’t used.