KERN & SOHN LA 300-2 User Manual

Instruction manual la (vertical type), Sauter gmbh

Sauter GmbH

Tieringerstr. 11-15

Tel: +49-[0]7433- 9976-174

D-72336 Balingen

E-Mail: [email protected]

Fax: +49-[0]7433-9976-285

Internet: www. sauter.eu

Instruction Manual

LA (vertical type)

LA_V-BA-e-1110

1

DIGITAL LENGTH METER

Model: LA

Specifications

Measuring Range: 0-150 mm/ 0~6’’

Resolution: 0.1 mm/0.01’’

Max. Measuring Speed: 1.5 m/s

System: Non-contact linear CAP

Power: one 1.5V silver-oxide button cell

(life: 1 year in continuous operation)

Working Temperature: 0° up to 40°C

Storage Temperature: -20° up to +60°C

Humidity allowed: ≤ 80%

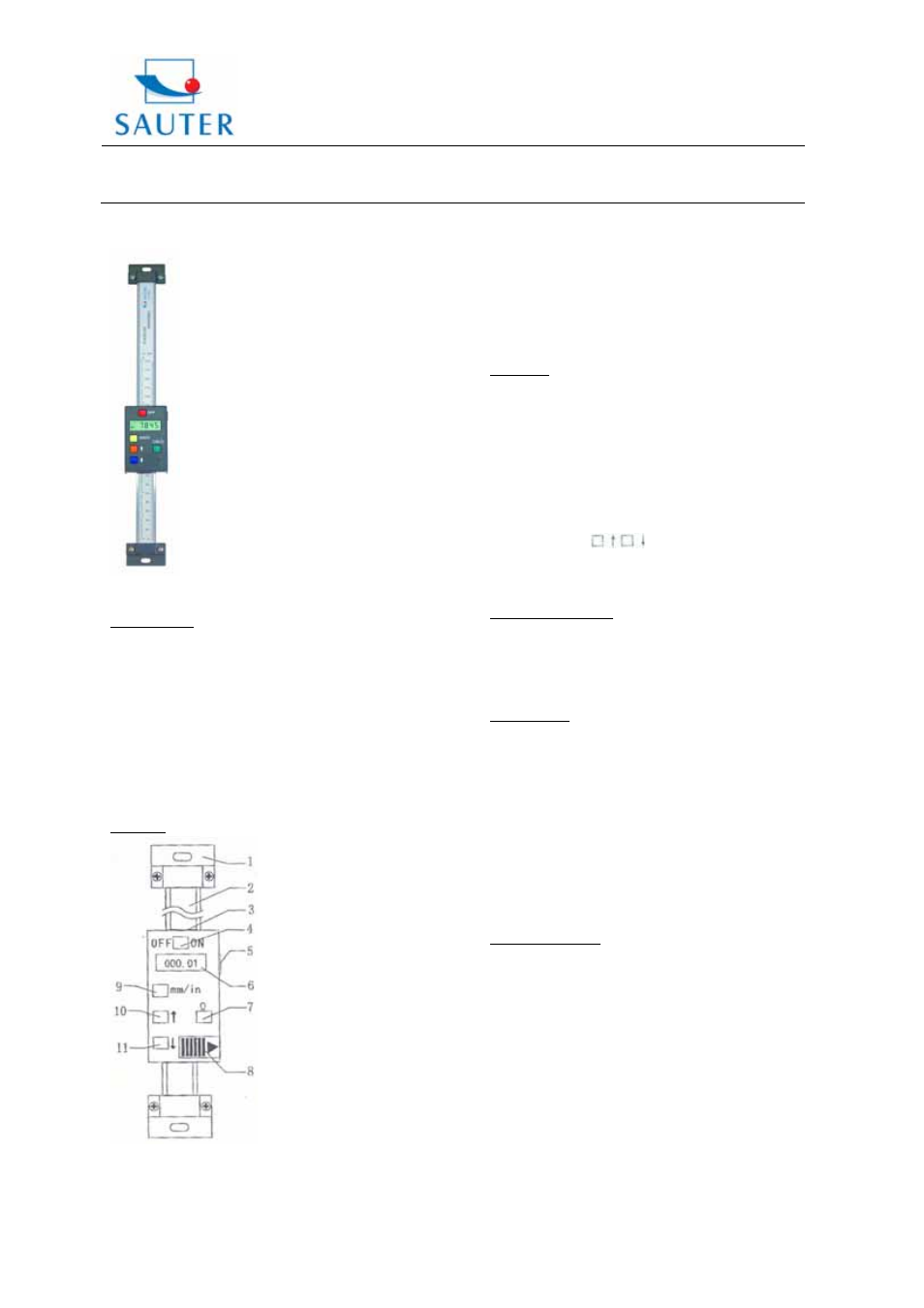

Structure

1. Bracket

2. Scale

3. Slider

4. ON/OFF

Key

5. Data

output

port

6. LCD

Display

7. Zero-

Key

8. Battery/Battery

cover

9. mm/inch

Key

10. Upper

presetting

Key

11. Lower

presetting

key

Functions

1. Power switch: Power on/ Power off

2. mm/ inch interchange: This button has to be pressed to

choose the metric or the inch system alternatively.

3. Zero-setting: After power is switched on and this button

is pressed, the display will be set back to Zero.

4. Preset buttons

. If these buttons are pressed,

the display will decrease or increase. It has to be released,

if the number to be preset is reached.

Battery replacement:

a) The frame cover has to be unscrewed

b) The battery cover has to be taken off and the cell, with

the positive side facing out, has to be replaced.

c) The cover has to be put on again.

Maintenance:

a) The working faces have to be kept clean and dry.

Prevent liquids from getting into the frame lest, because

the electronics might be damaged. In case that liquids

have got in, the frame has to be taken apart and dried up

under 60°C.

b) The scale body has to be cleaned with a soft fabric or

liquid sink soap. Do not use petroleum based lacquer

thinner, industrial alcohol or petroleum spirits. Organic

solutions are not allowed.

c) Never apply power pressure on any part of the scale lest

it damages the housing.

Fixing Instructions

a) Check to see if there has been any damage to the scale

unit. If so, please contact our company immediately.

b) At least 50 mm safety space should be left for the

sensor when the working (moving) part reaches its limits.

The screws at the ends have to be fixed in the way that the

sensor won’t be damaged by the working part going

beyond its limits.

c) One end has to be fixed while the other one is kept

floaing (moveable). The working part has to be moved

several times and the end positions of the scale have to be

adjusted (or gaskets have to be put on) until the direction

of the working part is parallel to the one of the scale.

d) The screws have to be fastened on both ends and the

connector. Parallelism has to be maintained. The

connector has to be kept from running when in operation.