KERN & SOHN TD 225-0.1US User Manual

Instruction manual td_us, Sauter gmbh

Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: [email protected]

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

Instruction Manual

TD_US

TD_US-BA-e-1310

1

DIGITAL THICKNESS GAUGE

Model: TD 225-0.1 US

Table of contents

1. Features

2. Specifications

3. Front panel description

4. Material selection

5. Calibration

6. Measuring procedure

7. Measuring by velocity setting

8. Battery replacement

9. Declaration of conformity

Annotation: It is strongly recommended to calibrate

the new instrument before the first use, as

described in paragraph 5. By doing this it

will be achieved a much better measure-

ment result right from the start.

1. Features

* The exclusive Micro- computer LSI offers high

measurement accuracy.

* The instrument offers high power of emission and a

wide spectrum of receiving sensitivity.

Sensors of different frequencies can be identified.

Rough surfaces, even cast iron, can be measured.

It is used in almost all kinds of industries.

* Convenient to measure the thickness of many materials,

e.g. steel, cast iron, aluminium, red copper, brass, zinc,

quarz glass, Polyethylen, PVC, grey cast iron, nodular

cast iron.

* Automatic power-off to preserve batteries.

* Date transfer to PC possible. Cable and software can be

obtained as optional accessory.

2. Specifications

Display: 4 digits, 10mm LCD

Range: 1.0 to 200mm (45# steel)

Resolution: 0.1mm / 0.001 inch

Accuracy: ± (0.5%n+0.1)

Sound velocity: 500 to 9000m/s

Power supply: 4×1.5V AAA (UM-4) battery

Operating conditions: Temperature: 0 to 50°C

Humidity: <80%

Size: 120 x 62 x 30mm (4.7 x 2.4 x 1.2 inch)

Weight: about 164g (not including batteries)

Accessories: Carrying case

Operation manual

Ultrasonic sensor

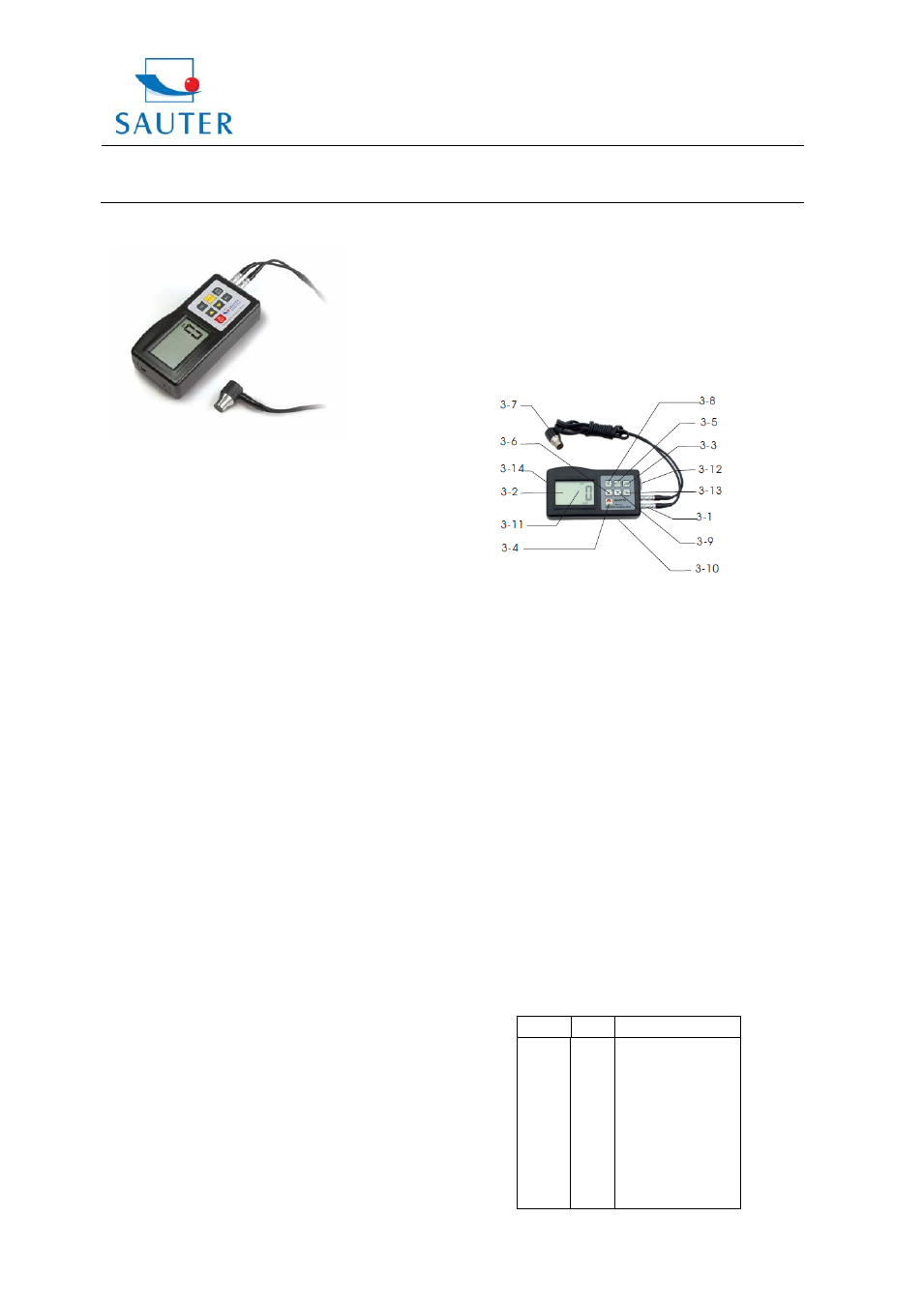

3. Front panel description

3- 1 Sensor plug

3- 2 Display

3- 3 mm/ inch key

3- 4 Power- key

3- 5 Material selection key

3- 6 Plus- key

3- 7 Ultrasonic sensor

3- 8 Calibration key

3- 9 Minus- key

3-10 Battery compartment/ cover

3-11 Coupling indicator

3-12 Base plate

3-13 Velocity key

3-14 RS-232C interface

4. Material selection

4.1 The instrument has to be switched on by the

Power- key 3-4.

4.2 The Material selection key 3-5 has to be pressed and

the display 3-2 will show the code `cdxx` or `xxxx`.

`cd` is the abbreviation for `code` and `xx` is a

number among 0.1 and 11 that stands for the material

to be measured as shown in the scale below.

. `xxxx` is a 4-digit number describing

the sound velocity of the material defined by the user.

The `cdxx` material relationship is as follows:

Nr.

Code

Material

1

2

3

4

5

6

7

8

9

10

11

12

cd01

cd02

cd03

cd04

cd05

cd06

cd07

cd08

cd09

cd10

cd11

xxxx

Steel

Cast iron

Aluminium

Red copper

Brass

Zinc

Quarz glass

Polyethylen

PVC

Grey cast iron

Nodular cast iron

Sound velocity