Step 6 — provide for condensate disposal – Carrier 50SX024-060 User Manual

Page 20

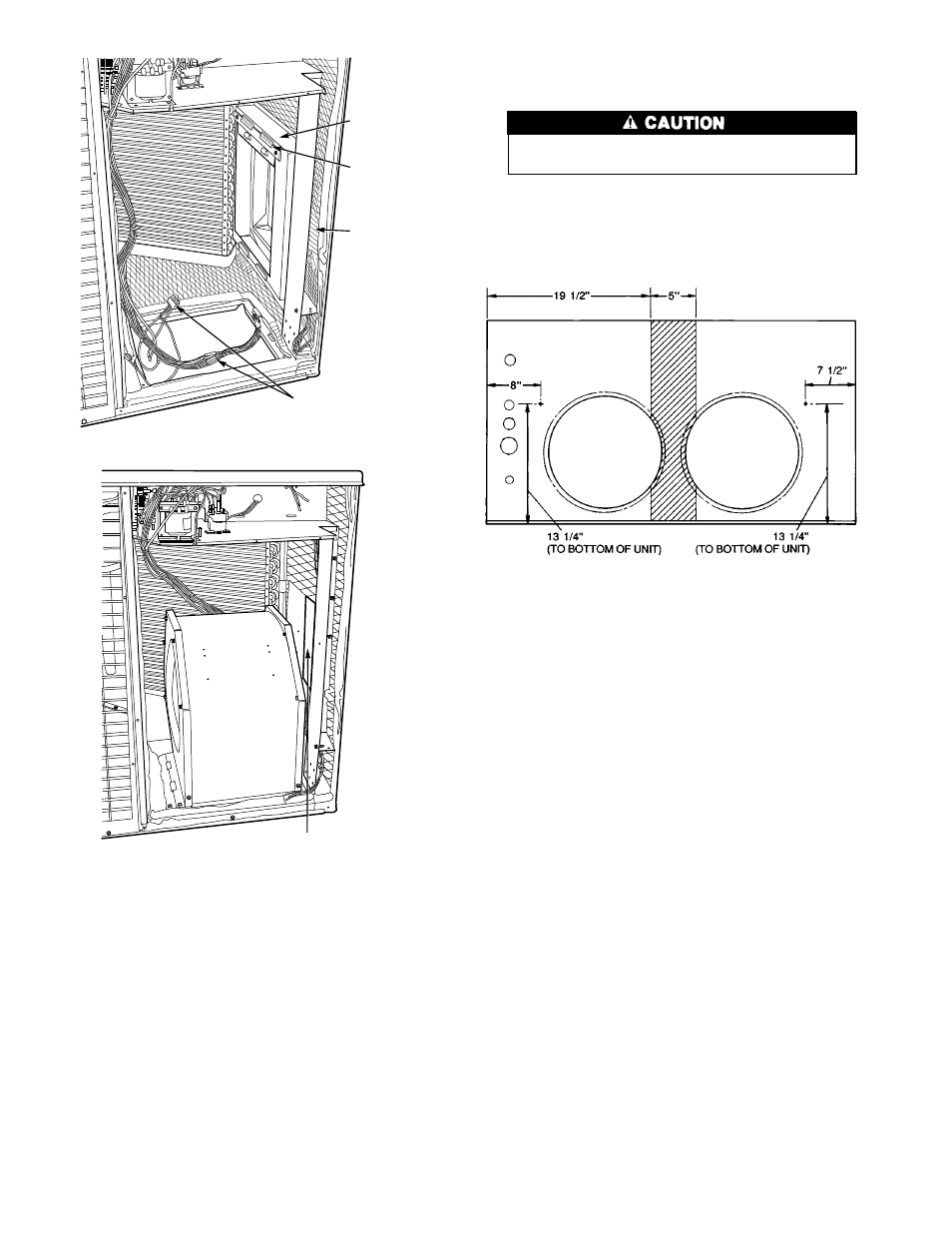

ACCESSORY DUCT FLANGE KIT INSTALLATION —

Refer to Fig. 26 for duct adapter dimensions and hole

locations.

1. Mark hole locations shown in Fig. 26.

2. At marked locations, drill holes using a no. 26 (.147-in.)

twist drill.

3. Partially secure duct flanges using two of the no. 10,

1

⁄

2

-in.

screws provided.

4. See the following caution. Using remaining holes in duct

flanges as templates, drill the remaining holes with the

no. 26 (.147-in.) drill.

Do not drill deeper than

1

⁄

2

-in. into shaded area shown

in Fig. 26. Damage to refrigerant coil could result.

5. Fully secure the duct flanges using the remaining screws

provided.

The finished kit installation accommodates a 14

3

⁄

4

-in. x

14

3

⁄

4

-in. duct.

Step 6 — Provide for Condensate Disposal

NOTE: Be sure that condensate-water disposal methods com-

ply with local codes, restrictions, and practices.

Unit disposes of condensate through a

3

⁄

4

-in. NPT fitting

which exits through the compressor access panel. See

Fig. 2-9 for location of condensate connection.

Condensate water can be drained directly onto the roof in

rooftop installations (where permitted) or onto a gravel apron

in ground-level installations. Install a field-supplied conden-

sate trap at end of condensate connection to ensure proper

drainage. Make sure that the outlet of the trap is at least

1 in. lower than the drain-pan condensate connection to pre-

vent the pan from overflowing. See Fig. 27. Prime the trap

with water. When using a gravel apron, make sure it slopes

away from the unit.

If the installation requires draining the condensate water

away from the unit, install a 2-in. trap using a

3

⁄

4

-in. FPT

connection. See Fig. 27. Make sure that the outlet of the trap

is at least 1 in. lower than the unit drain-pan condensate con-

nection to prevent the pan from overflowing. Prime the trap

with water. Connect a drain tube using a minimum of

3

⁄

4

-in.

PVC,

3

⁄

4

-in. CPVC, or

3

⁄

4

-in. copper pipe (all field supplied).

Do not undersize the tube. Pitch the drain tube downward at

a slope of at least 1 in. for every 10 ft of horizontal run. Be

sure to check the drain tube for leaks. Prime trap at the be-

ginning of the cooling season start-up.

PLUG ASSEMBLIES

RACEWAY

FILLER

BRACKET

BLOWER

SHELF

Fig. 24 — Filler Bracket and Blower Shelf

HORIZONTAL DUCT OPENING

Fig. 25 — Housing Placed for Vertical Airflow

NOTE: Do not drill more than

1

⁄

2

-in. deep in shaded area.

Fig. 26 — Duct Flange Kit — Locating Holes

(Typical)

20