Great Planes CAP 232 1.60 ARF - GPMA1410 User Manual

Page 9

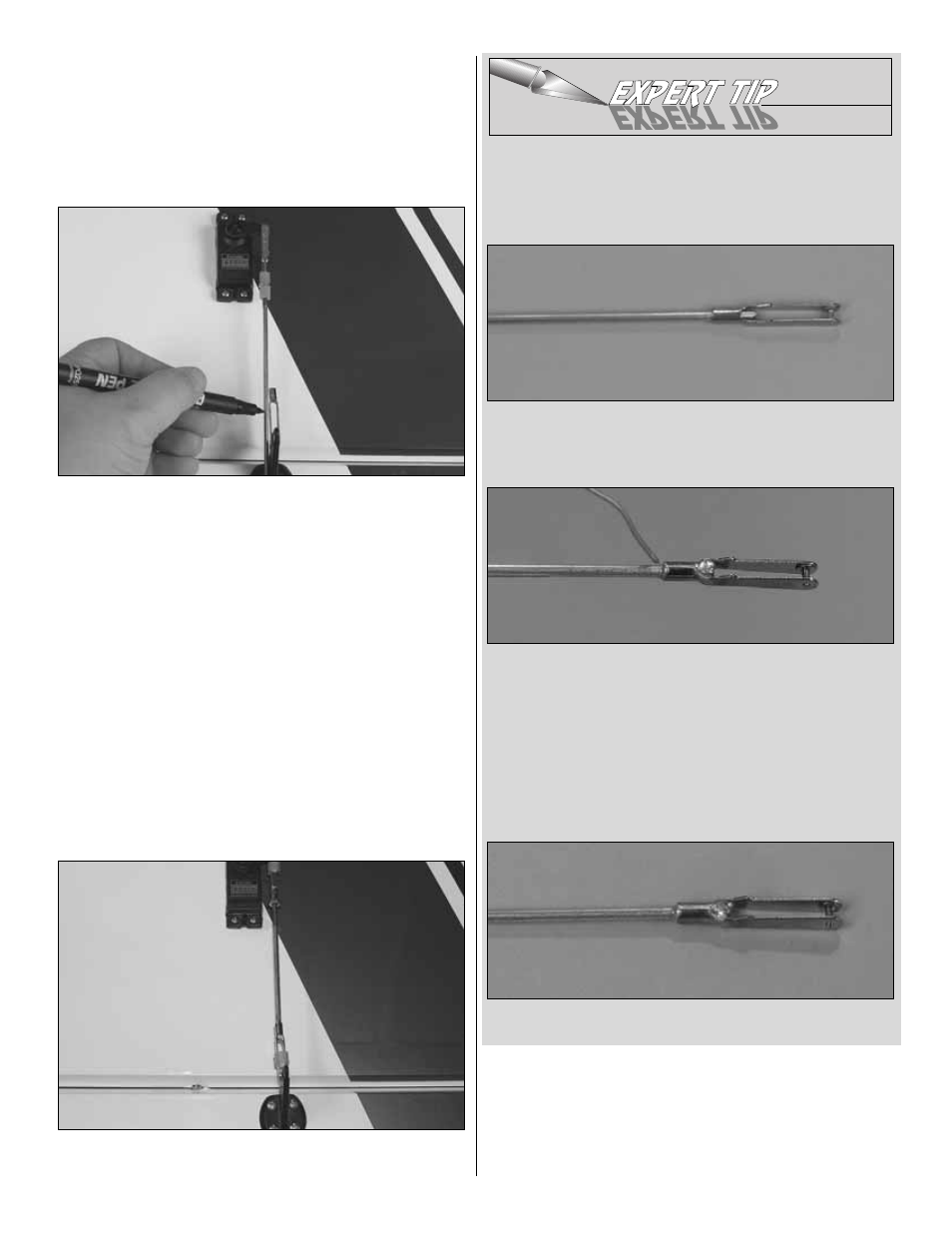

and aligning it with the servo. Mark the location for the screw

holes. Drill pilot holes in the marks you made with a 1/16"

[1.6 mm] drill bit, being careful not to drill through the

aileron. Secure the control horn to the aileron with four #4 x

1/2" [13 mm] screws. Remove the screws, harden the holes

with thin CA, and then reinstall the screws.

❏ ❏

4. Align the pushrod with the clevis on the control horn

and make a mark using permanent marker or Panel Line

Pen where the pushrod extends 1/8" [3 mm] into the open

area of the clevis. Trim the 4-40 rod to length.

❏ ❏

5. Remove the clevis and pushrod assembly from the

servo and the solder clevis from the control horn.

❏ ❏

6. Attach the solder clevis to the pushrod using the

expert tip at the end of this section.

❏ ❏

7. Reattach the pushrod assembly as shown. Be sure

to slide the silicone retainers over the clevises.

HOW TO SOLDER

❏

A. Use denatured alcohol or other solvent to thoroughly

clean the pushrod. Use coarse sandpaper to roughen the

end of the pushrod where it is to be soldered.

❏

B. Apply a few drops of soldering flux to the end of the

pushrod. Position the clevis so that 1/8" of the pushrod

protrudes into the open area of the clevis.

❏

C. Simultaneously heat the clevis and pushrod. Apply silver

solder (GPMR8070) to the joint. The heat of the parts being

soldered should melt the solder, thus allowing it to flow.

❏

D. Immediately after the solder has solidified, but while it

is still hot, carefully use a cloth to quickly wipe off the flux

before it hardens. Important: After the joint cools, coat with

oil to prevent rust. Note: Do not use the acid flux that comes

with silver solder for electrical soldering.

❏

E. This is what a properly soldered clevis looks like; shiny

solder with good flow, no blobs, flux removed.

❏

8. Repeat steps 1-7 for the other aileron servo.

9