Great Planes CAP 232 1.60 ARF - GPMA1410 User Manual

Page 10

❏

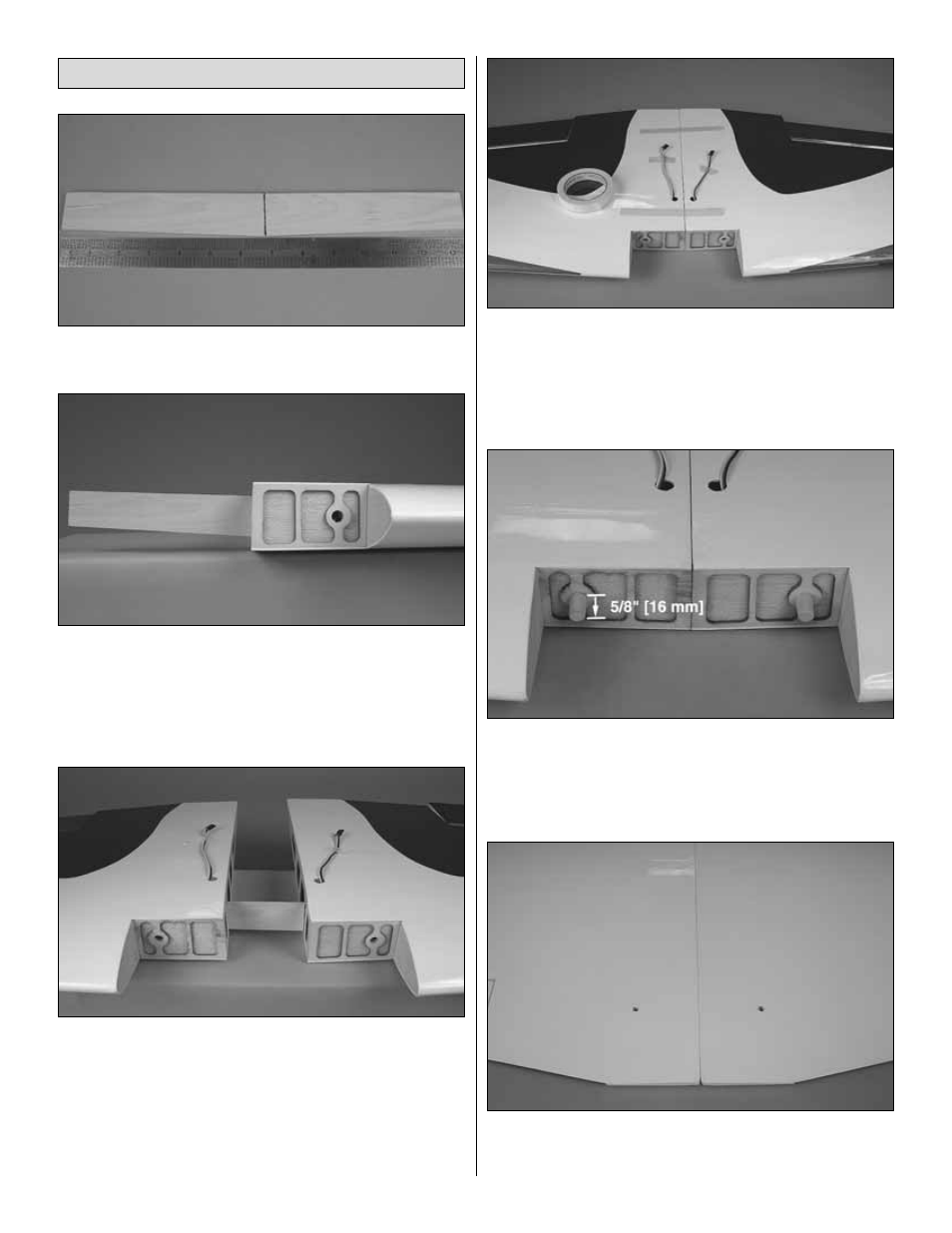

1. Locate the wing joiner. Measure and mark the centerline

of the joiner.

❏

2. Test fit the wing joiner in one half of the wing. Sand as

needed to allow the joiner to fit snug in the wing. Then slide

the other wing half onto the joiner. There should be no gap

between the wing halves when joined. Note the direction of

the joiner. The “V” of the joiner should be towards the bottom

of the wing.

❏

3. When satisfied with the fit, separate the wing panels

and remove the joiner. Mix a large batch of epoxy, enough to

cover one half of the wing joiner and the inside of one wing

joiner pocket. Half of one epoxy mixing cup, or 1/2 oz of

epoxy should work fine. Coat half of the wing joiner and one

wing joiner pocket with epoxy and insert the joiner. Clean up

any epoxy that oozes out using a paper towel and denatured

alcohol. Allow the epoxy to fully harden before proceeding.

❏

4. Mix another large batch of 30-minute epoxy, 1 oz should

do. Coat the other half of the wing joiner, wing joiner pocket

and the two wing roots with 30-minute epoxy. Join the two

wing halves and hold them together with masking tape until

the epoxy has completely hardened. Clean up any excess

epoxy with alcohol and a paper towel.

❏

5. Locate the two 3/8" [10 mm] x 2" [51 mm] wooden

wing dowels. Round the edges of the dowels. Test fit the

dowels into the holes in the forward center section of the

wing as shown. Approximately 5/8" [16 mm] of the dowel

should be sticking out of the wing. Glue in place using epoxy.

❏

6. Locate the wing bolt holes in the aft center section of

the wing. Remove the covering from these holes on the top

and bottom of the wing using a sharp hobby knife.

Join the Wing

10