Great Planes CAP 232 1.60 ARF - GPMA1410 User Manual

Page 22

❏

3. Remove the template and enlarge the holes using a

1/4" [6 mm] drill bit.

❏

4. Mix a small amount of 30-minute epoxy. Apply a few

dabs of epoxy to the front of four 10-32 or 1/4" blind nuts (not

included). Hold the blind nut against the back of the firewall

and thread a 10-32 or 1/4" bolt (not included) with a washer

into the blind nut. Tighten the bolt to draw the blind nut into

the wood. Be careful to avoid getting excess epoxy into the

threads on the blind nuts.

❏

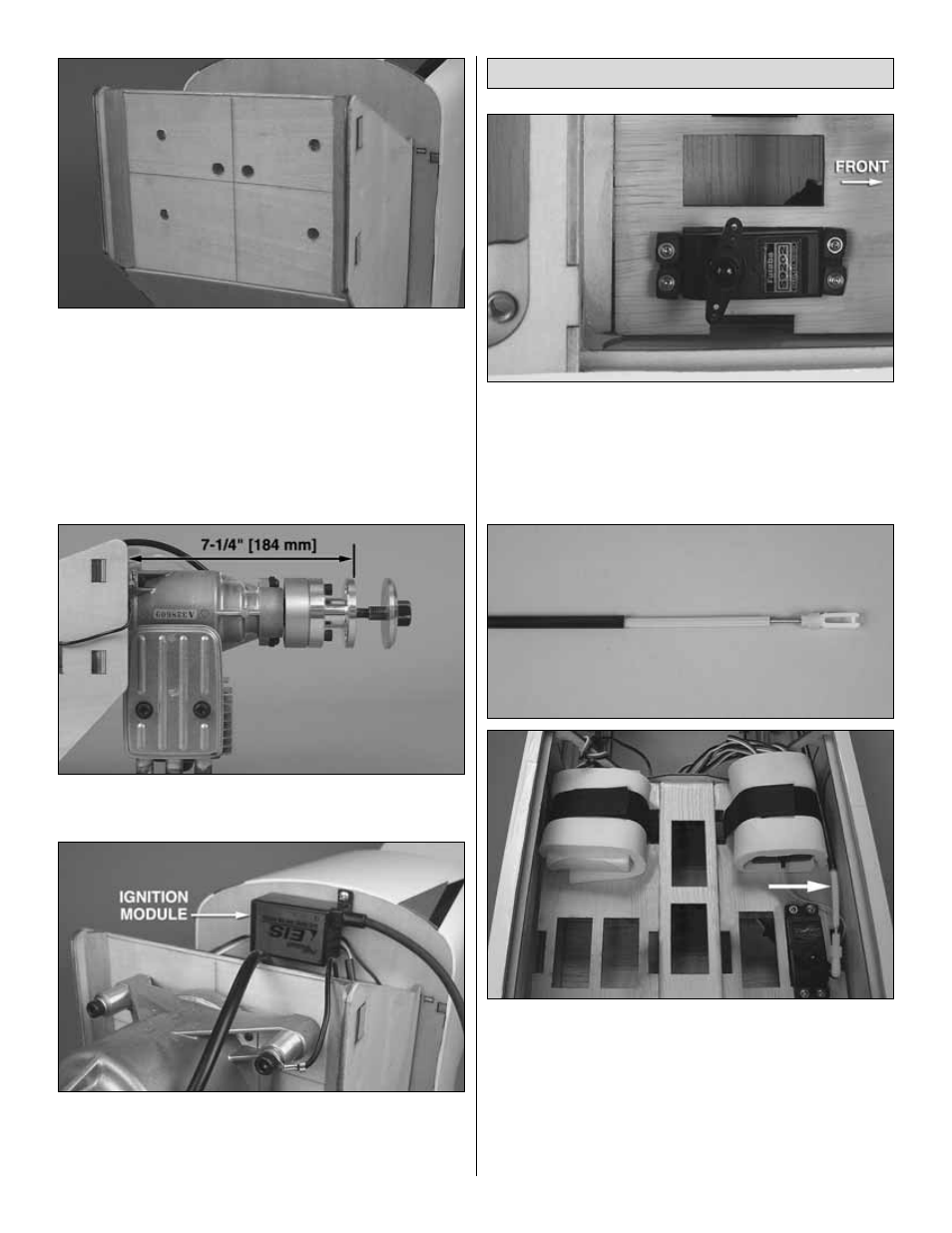

5. Mount the engine to the firewall so that the distance

from the firewall to the drive washer is 7-1/4" [184 mm].

❏

6. Mount the electronic ignition unit as shown.

❏

7. Following the guidelines in the shaded box previously

shown, install an ignition kill switch into the fuselage.

❏

1. Install the throttle servo into the servo tray using the

hardware provided by your servo’s manufacturer. Choose

the mounting position that gives you the most direct route to

your carburetor. For the Fuji-Imvac 43cc gas engine,

typically the servo location would be in the far right mounting

position as shown.

❏

2. Using a non-metallic flexible pushrod system, connect the

throttle servo to the carburetor on your engine. Shown in the

photo is the Semi-Flexible Pushrod system from Great Planes

(GPMQ3714). This system comes with ideal components for

this type of throttle connection. Since engine installations can

vary, the location of the holes in the formers and firewall for the

pushrod to route through will also vary. For our installation of the

Fuji-Imvac 43cc gas engine, the throttle pushrod was routed

along the right side of the fuselage as shown.

Install the Throttle Servo (Gas Engine)

22