Great Planes 27% Extra 330S ARF - GPMA1413 User Manual

Page 23

23

❏

5. Make mounting straps from the included Velcro strips

by cutting them to the correct length for the receiver and

battery. Mount the receiver and battery to the tray with 1/4"

[6mm] R/C foam rubber. If you want you could use CA to

glue the Velcro to the bottom of the tray. This will make re-

fastening the straps around the battery and receiver easier if

you ever remove and re-install them later.

❏

6. Mount the radio tray to the rails in the fuselage with four

#2 x 1/2" [13mm] screws and #2 washers–again, don’t forget

to harden the screw holes with thin CA.

❏

7. Hook up the throttle as instructed below for the type of

engine you are using.

Glow Engine Throttle Hookup

❏

1. Temporarily mount the muffl er to the engine so you will know

where to locate the throttle pushrod so it won’t interfere with the

muffl er. If you haven’t yet done so, mark the fi rewall where the

throttle pushrod will go through and drill a 3/16" [4.8mm] hole

at that mark (this will probably require temporary removal of the

engine). Also be certain to drill the hole where the pushrod will

not interfere with the fuel tank behind the fi rewall and do not drill

into the fuel tank.

❏

2. Hook up the throttle using the hardware listed below.

Glow engine throttle pushrod hardware:

❏

2-56 x 36" [910mm] wire pushrod

❏

3/16" x 36" [4.8 x 910mm] gray pushrod guide tube

On the servo end:

❏

brass screw-lock pushrod connector

❏

nylon retainer

❏

4-40 x 1/8" [3.2mm] SHCS

On the engine end:

❏

nylon ball link

❏

0-80 ball link ball

❏

0-80 nut

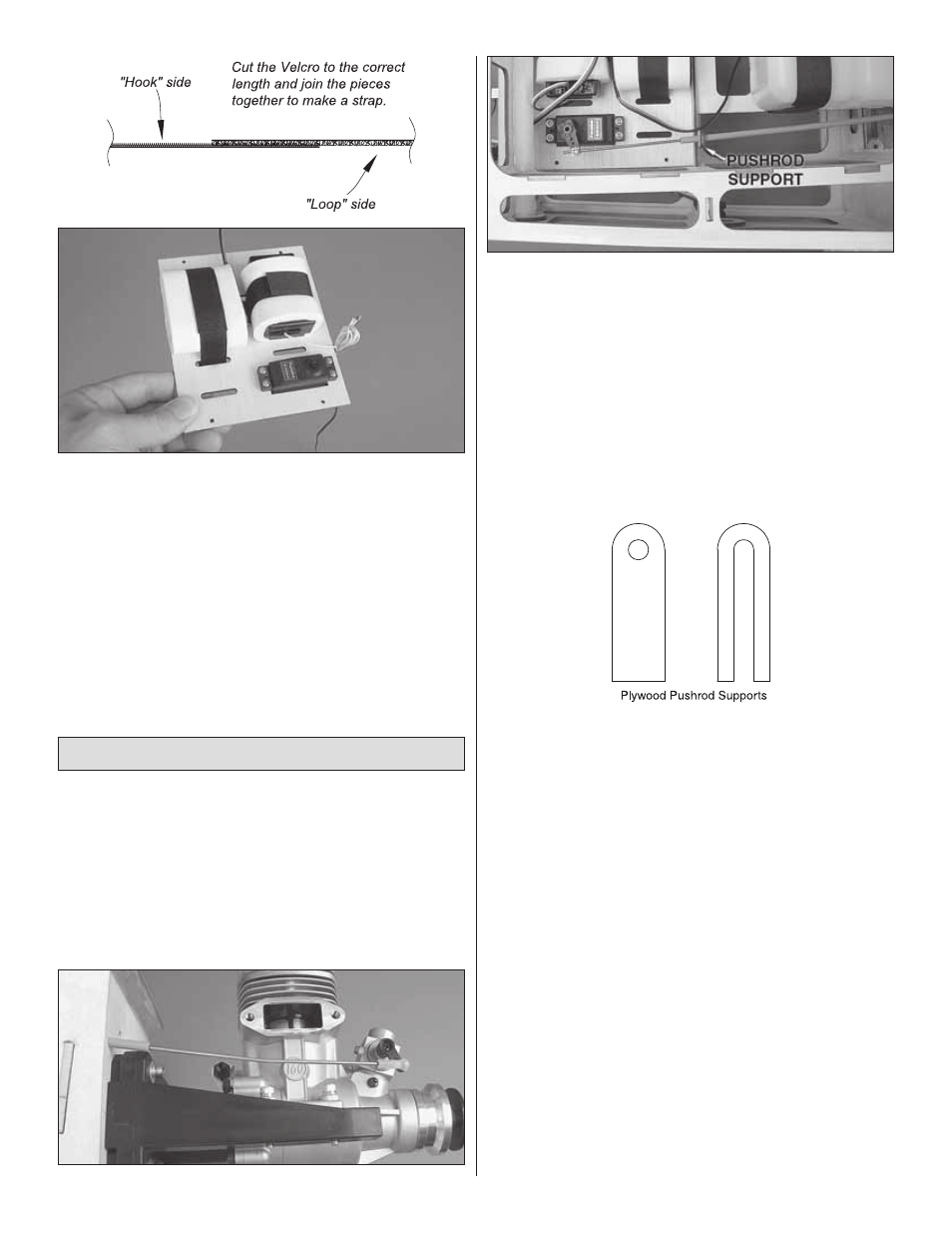

Note that, for the O.S. 1.60 FX shown, the pushrod goes

through the fi rewall at a slight angle toward the servo, so you

may need to use a hobby knife to angle the hole accordingly.

Use one of the plywood pushrod supports to secure the aft

end of the pushrod near the throttle servo. Cut the gray pushrod

guide tube to the correct length, then use coarse sandpaper to

roughen both ends where it goes through the fi rewall and the

pushrod support. Glue the tube and the support into position

with medium CA. Cut the pushrod wire to the correct length

and make a slight bend near the end as necessary to align

with the ball link ball on the carburetor arm.