Great Planes Extra 300S 40 Kit - GPMA0235 User Manual

Page 8

8

❏

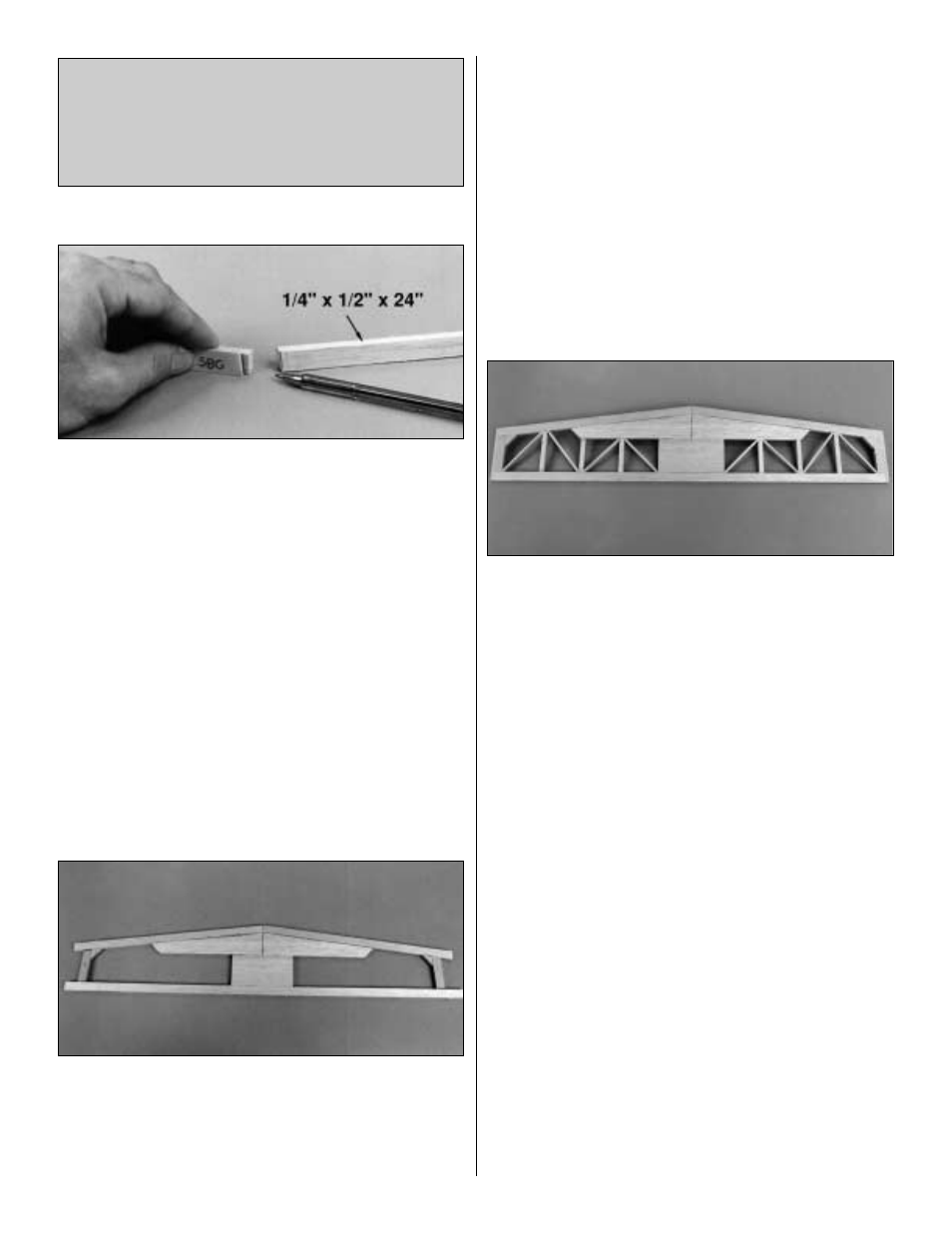

2. Cut a 1/4" x 1/2" x 24" balsa stick (do not use the

30" long stick–it's for the fuse turtle deck) into two 12" long

pieces to make the stab leading edg es. Use the

die-cut 1/8" plywood stab bevel gauge (SBG) to mark,

then cut one end of both sticks. Don't cut the tips of the

LE's yet. Cut and “square them up” with the end of the stab

after you remove it from the plan at step 7. Glue the stab

LE's to the LE doubler with medium CA and pin them in

position over the plan.

❏

3. Glue a 1/4" x 1/2" x 24" balsa stick to the stab center

and pin it in position over the plan for the stab trailing edge.

Use the plans or a straightedge as a guide to make sure the

stab trailing edge is straight as you pin it in position.

Hint: If possible, choose one of the softer pieces of wood for

the stab trailing edge. This will make cutting the hinge slots

easier than if you were to use a harder piece of wood.

❏

4. Cut the ends of the stab from another 1/4" x 1/2" x 24"

balsa stick using the stab bevel gauge to cut them at the

correct angle. Glue the ends of the stab to the leading and

trailing edges and pin them in position. Make the gussets

from the 1/4" x 1/2" stick and glue them in position (you can

use the stab bevel gauge to make the gussets too).

❏

5. Make the 1/4" tail ribs from a 1/4" x 1/4" x 24" balsa

stick, then glue them in position. You can use the stab bevel

gauge for two of the ribs and the 2" wide piece you cut off

the stab center as a gauge to cut the remaining four 1/4"

ribs to exact length.

Hint: Use a sharp single edge razor blade to cut the tail ribs.

❏

6. Make the 1/8" tail ribs from a 1/8" x 1/4" x 24" balsa

stick, then glue them in position. We recommend cutting

these tail ribs with a single edge razor blade too.

Sorry, no

gauges for these. You'll just have to rely on pure skill!

❏

7. Remove the stab from your building board. Inspect all

the glue joints and add CA to any joints that don't look

strong. Cut the ends of the leading and trailing edges so

they extend past the end of the stab by about 1/16". Use

your bar sander to finish the job by sanding the ends of the

LE's and TE so they are flush with the end of the stab. Cut

the 1/8" x 1/4" tips, then glue them to the end of the stab.

❏

8. Use your bar sander or a large sanding block and

220-grit sandpaper to sand the entire top and bottom

surface of the stab until it is flat and even. Be careful while

sanding so you do not over-thin any one particular area of

the stab or gouge the stab ribs by snagging the sandpaper

on them.

There, that was kind of fun wasn't it? Let's continue to build

the elevators, fin and rudder.

❏

9. Follow the recommended building sequence that follows

to build the elevators, fin and rudder from the same sizes of

balsa sticks you used for the stab. Use the die-cut 1/8"

plywood elevator bevel gauge (EBG) where appropriate. The

elevator root ends are made from the leftover piece you cut

from the 1/4" x 2" x 6" balsa sheet at step 1.

Hint: Cut one of the elevator root ends from the plan and

use it as a template to make the balsa part. The rudder

balance tab, rudder bottom and fin base are made from

the 1/4" x 2" x 10" balsa sheet.

Note: Refrain from using excessive accelerator. Even hours

after it's sprayed on, residual accelerator can prematurely

and unexpectedly cure the CA you use later on nearby glue

joints. Unless you must handle or remove the part from your

building board right away, we recommend using no

accelerator at all.