Great Planes Extra 300S 40 Kit - GPMA0235 User Manual

Page 32

❏

2. Cut one of the outer pushrod guide tubes left over

from the rudder and elevator guide tubes to a length of

7-3/4". Use coarse sandpaper to roughen the outside of the

tube so the glue will stick.

❏

3. Fit the tube through the hole you drilled in the firewall

and former F-2B.

Note: If you are mounting a 4-stroke engine you may have

to drill another hole in F-2B to reroute the pushrod.

❏

4. Bend and cut the 17-1/2" throttle pushrod wire to fit

your engine installation using the drawing on the fuselage

plan as a guide. Install a nylon clevis and insert the pushrod

through the guide tube. Make adjustments to the bends in

the wire so the pushrod aligns with the carburetor arm on

the engine, then temporarily connect the clevis to the carb

arm. Temporarily mount the muffler and make sure the

throttle pushrod will not interfere with the muffler. Make

adjustments to the bends in the wire if necessary.

❏

5. Install the servos in the servo tray spacing them apart

as necessary so the servo arms do not interfere with each

other. Temporarily install the brass Screw-Lock

™

Pushrod

connector in the throttle servo arm, then adjust the bend in

the throttle pushrod if necessary and fit it into the connector.

Note: Some modelers prefer to install the pushrods and

control horns after the model is covered. If this is your

preference skip ahead to step 15. Return to step 6 after you

have covered the model and joined the control surfaces to

the model with the hinges.

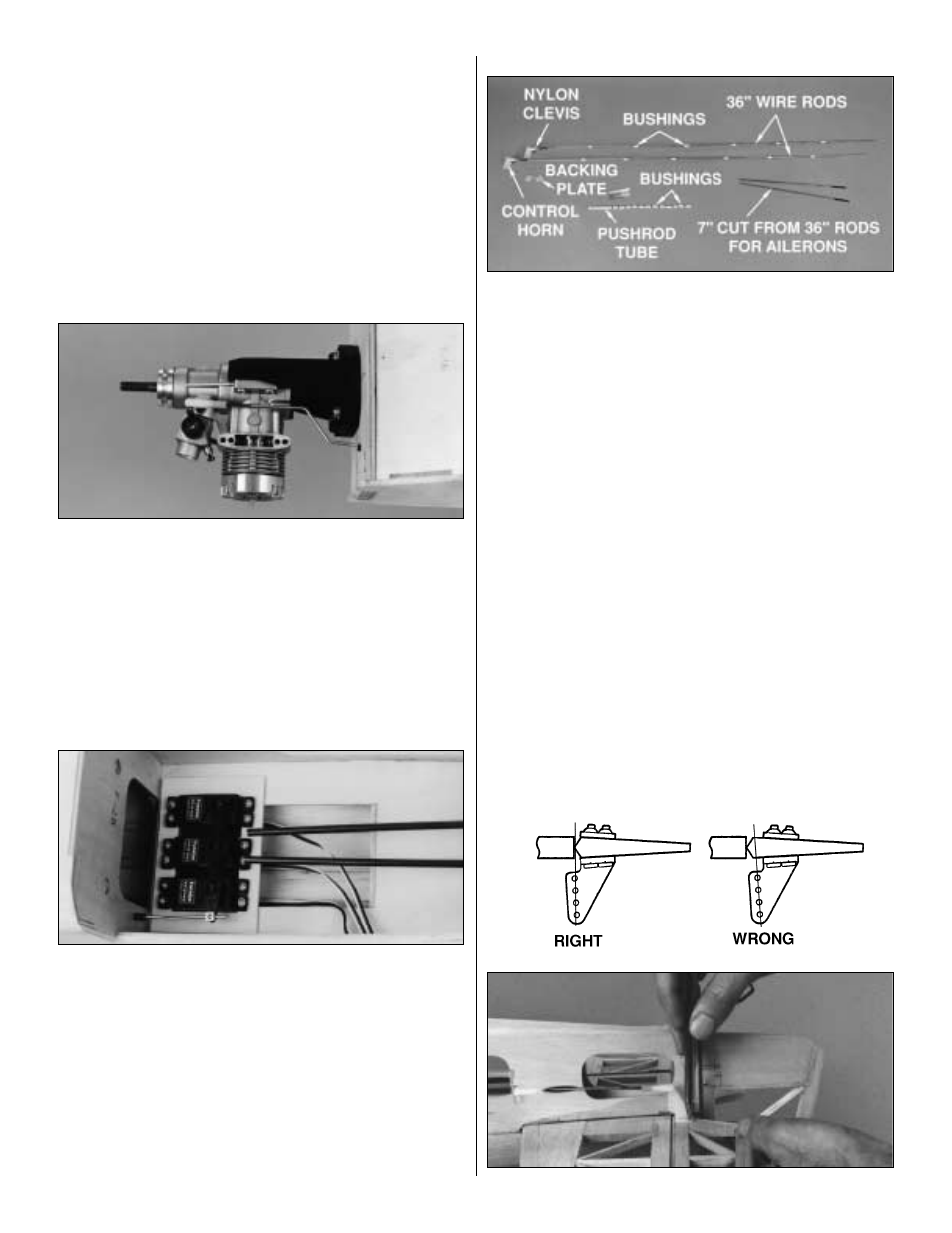

Use this photo for the next three steps.

❏

6. Cut 7" off one end of both 36" wire rods. Set the short

pieces aside and save them for the aileron pushrods.

Thread a nylon clevis about 20 turns onto the end of one of

the long rods, then remove the backing plate from a nylon

control horn and connect the horn to the clevis in the outer

hole. Make another pushrod assembly from the other long

rod with a clevis and control horn.

❏

7. Cut twelve 3/8" bushings from the 6-1/2" plastic inner

pushrod tube. Slide six bushings, evenly spaced, onto each

pushrod. Adjust the bushings nearest the ends of the rods

so they will not interfere with the ends of the guide tubes

and possibly become jammed during flight. If the bushings

slide onto the wires without much resistance use a drop of

thin CA to hold them in position.

Hint: Before installing the bushings, use a cloth saturated

with denatured alcohol or other solvent to wipe off the oil

left on the wires from the manufacturing process.

❏

8. Trim the plastic pushrod guide tubes that are glued

into the fuselage so they “end” about 2" aft of the elevator

and rudder servo arms. If you've used CA to secure the

plastic bushings on the wire pushrods, make sure it has

fully cured, then slide the pushrods into the guide tubes

from the back of the fuselage.

32