Great Planes Extra 300S 40 Kit - GPMA0235 User Manual

Page 33

❏

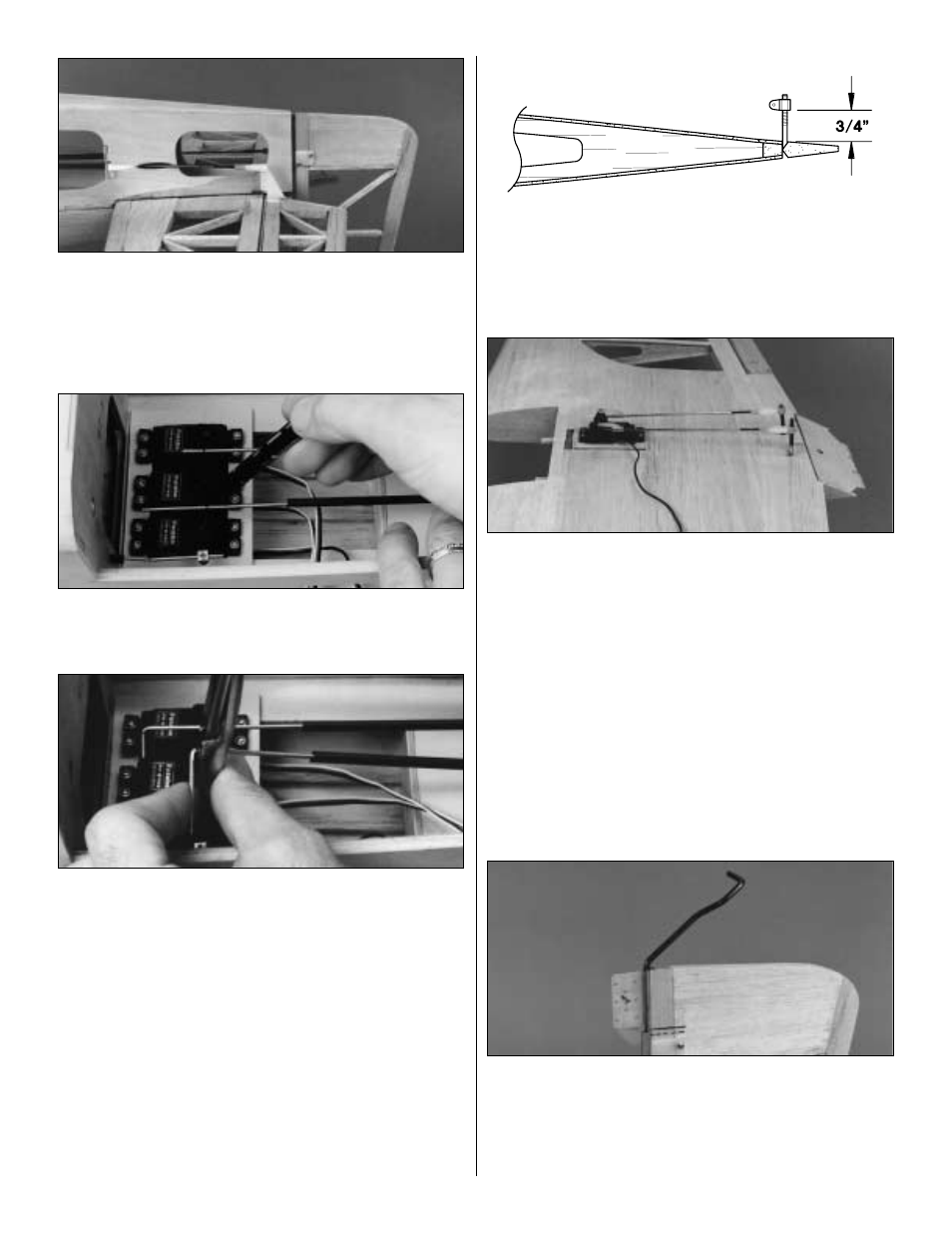

9. Position the control horns on the elevator and rudder

as shown in the sketch and on the plan. Use a ballpoint pen

to mark the location of the control horn mounting holes and

drill 3/32" holes at the marks. Temporarily mount the control

horns to the rudder and elevator with the backing plates

and 2-56 x 5/8" screws.

❏

10. With the servos centered and the control surfaces in

neutral position, use a felt-tip pen to mark where the

pushrods cross the mounting holes in the servo arms.

❏

11. Disconnect the clevises from the control horns, then

make a 90 degree bend at the marks you made. Temporarily

install a nylon Faslink on each pushrod, then cut the wire so

it slightly protrudes out of the Faslink.

Hint: If you prefer to bend and cut the pushrods out of the

fuselage remove the pushrods, then make the 90 degree

bends and cut the wire. Unscrew the clevises and reinstall

the pushrods in the guide tubes from the front, then screw

the clevises back on.

❏

12. Connect the pushrods to the servos with the Faslinks.

Note: If necessary, enlarge the holes in the servo arms

with a 5/64" drill bit (or a #48 drill for precision).

❏

13. Mount the aileron servo in the wing, then thread the

nylon 6-32 torque rod connectors on the torque rods until

they are 3/4" from the wing sheeting.

❏

14. Use the 7" long wire rods cut from the 36" pushrods

to make the aileron pushrods. Connect the pushrods the

same way you did for the elevator and rudder with the nylon

clevises and faslinks.

❏

15. If you haven't already done so, sand the bottom of

the rudder so it is even with the bottom of the fuselage,

then round the bottom of the rudder to match the trailing

edge. Mark the location of the tail gear wire on the rudder

and the nylon tail gear bearing on the fuselage.

❏

16. Remove the rudder and drill a 3/32" hole in the

leading edge at the mark you made for the tail gear wire,

then cut a groove for the nylon tail gear bearing (use a

5/32" brass tube sharpened at one end to cut the groove

the same way we showed you for the elevators.) Test fit the

tail gear wire in the rudder.

33