Great Planes Extra 300S 40 Kit - GPMA0235 User Manual

Page 36

❏

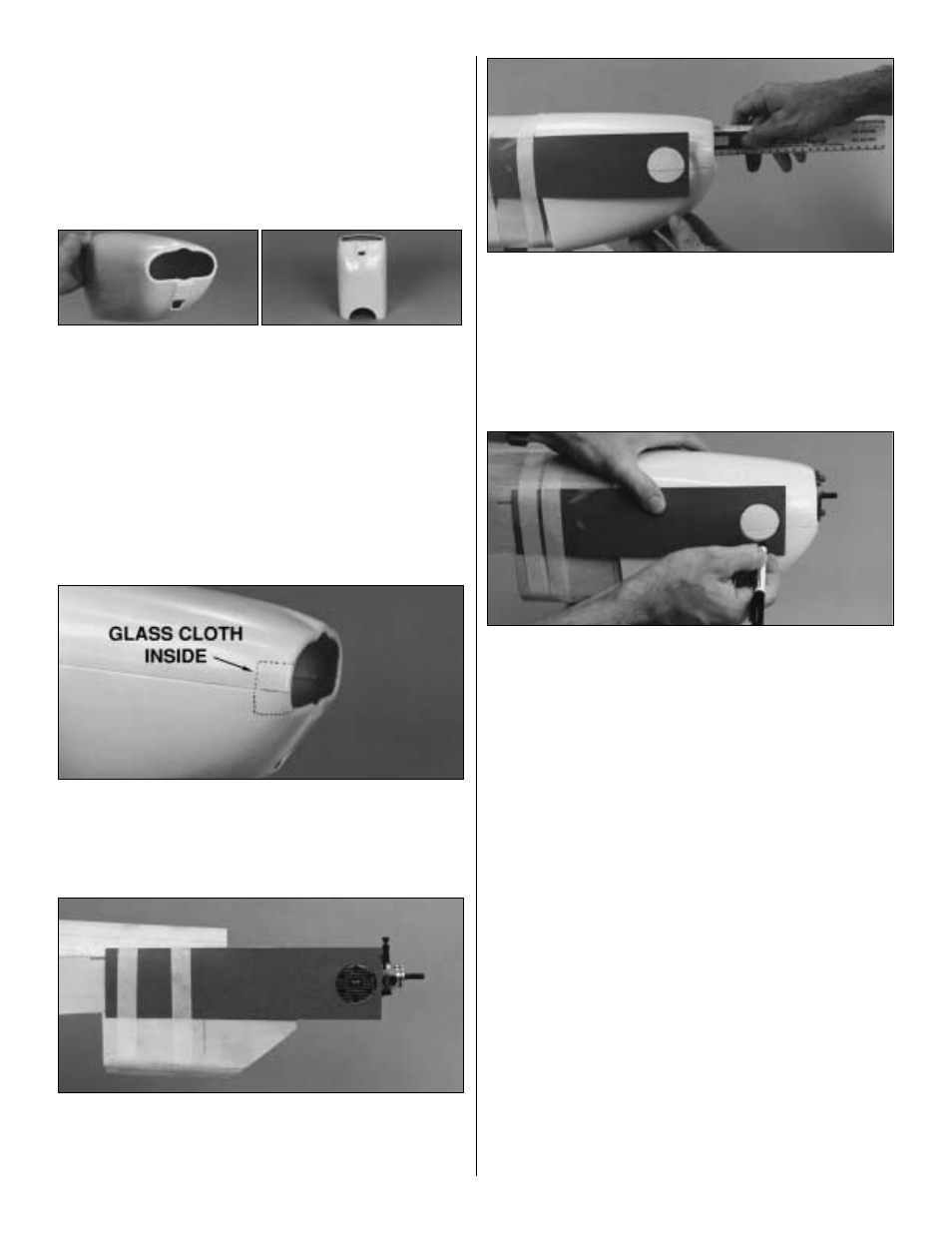

2. Tape the two pieces together, then wick a small

amount of thin CA along the seams of the overlapping

joints. After the CA has cured remove the tape and make

sure you have thoroughly glued the two pieces together by

inspecting the glue joints and adding thin CA if necessary.

❏

3. Use a sharp hobby knife or a MultiPro with a sanding

drum to accurately cut the engine openings at the front of

the cowl and the air exit at the rear of the cowl.

❏

4. Use coarse sandpaper to thoroughly scuff the inside

of the front of the cowl on both sides where there is no

overlapping glue joint.

❏

5. Use 30-minute epoxy to glue a 1" strip of glass cloth

across the glue joint inside the front of the cowl on both sides.

❏

6. Use a piece of thin cardboard or plastic to make a

template for the cutout in the cowl for the head of the

engine. Tape the template to the fuselage side accurately

indicating the position of the head.

❏

7. Place the backplate of your spinner on the engine and

measure the distance between the firewall and the

backplate (it should be 4-3/4"). Remove the engine from the

fuselage, then position the cowl on the fuselage so the

forward edge is 1/8" aft of the measurement you just made.

Use a ballpoint pen to lightly mark the location of the rear of

the cowl on the fuselage top.

❏

8. Align the cowl with the mark you made on the

fuselage, then use a felt-tip pen to transfer the hole in the

template onto the cowl.

Note: The circle you mark on the cowl may be slightly aft of

the actual position of the head of the engine due to the

upward sweep of the template when the the cowl is in position

.

Hint: For the most accuracy, mount the engine to the

fuselage and remove only the cylinder head. Position the

cowl, then install the spinner backplate on the engine. Align

the cowl with the spinner backplate (instead of the

reference line you marked on the fuselage top),

then

transfer the hole in the template onto the cowl.

❏

9. Remove the cowl and template, then remount the

engine (or the cylinder head). Cut out the hole in the cowl,

then test fit it to the fuselage (you may have to temporarily

remove the needle valve so it does not interfere with the

cowl.) Adjust the position and size of the hole as needed.

The location of the hole determines the clearance between

the front of the cowl and the back plate of the spinner.

Hint: Cut the hole in the cowl undersize at first so you can

make adjustments to its position without having to oversize it.

❏

10. Once you have made the hole in the cowl to clear

the engine, place the cowl on the fuselage and fit the back

plate of your spinner on the engine.

36