Install the hardware – Great Planes Extra 300S 40 Kit - GPMA0235 User Manual

Page 40

❏

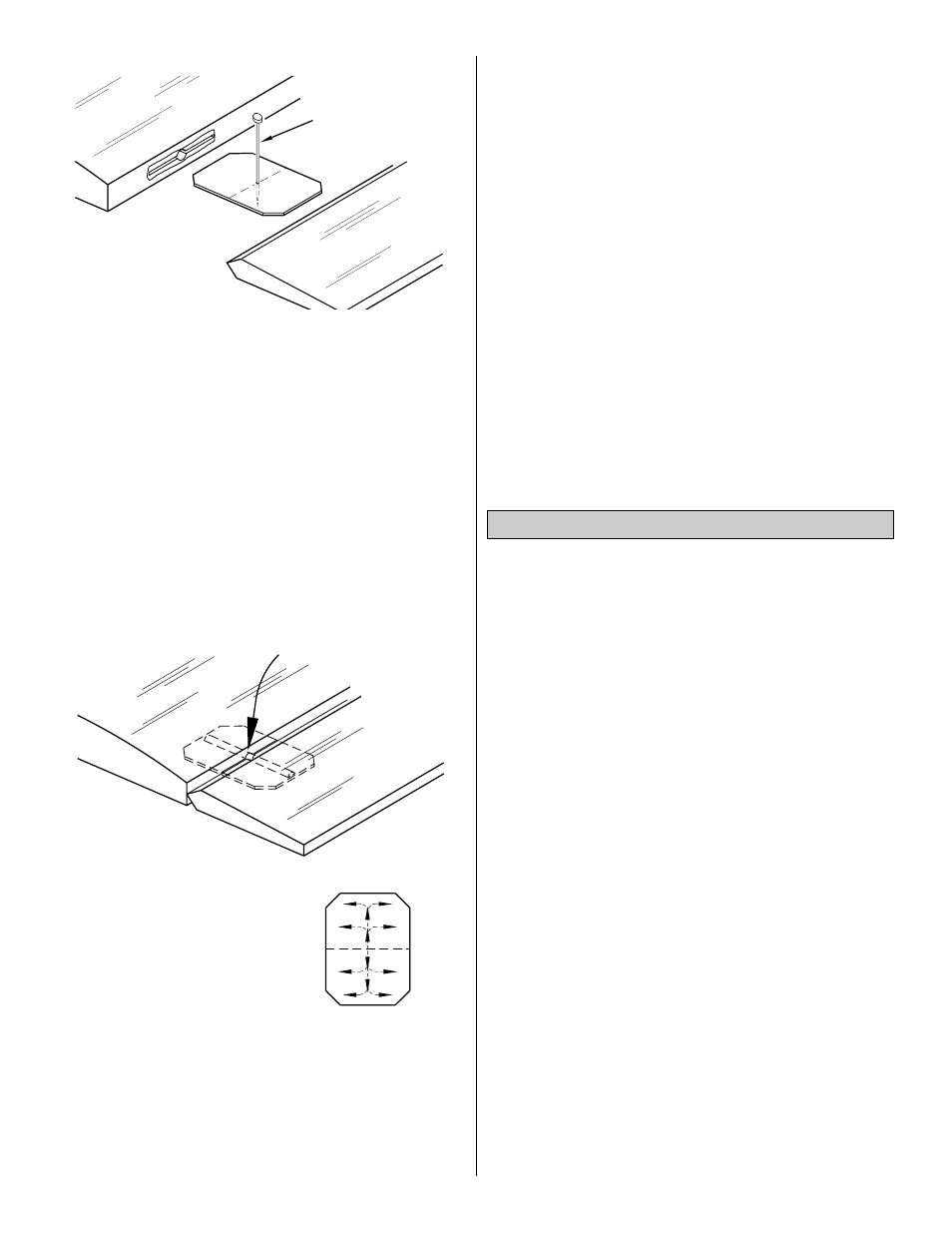

5. Without using any glue, fit the hinges in the elevators

or stab, then fill the holes in the elevators for the joiner wire

with 30-minute epoxy. Join the elevators to the stab and

joiner but do not glue the hinges yet. As you join the

elevators to the stab, confirm that the hinges are equally

inserted in the elevators and the stab. You may insert a

small pin in the center of the hinges to keep them centered.

❏

6. Remove excess epoxy that squeezes out of the

elevators with a cloth dampened with alcohol. Close the

hinge gap to 1/32" or less–it is best to have a

slight gap to

avoid inadvertently gluing the control surfaces together.

Remove the pins if you have used them to center the hinges.

❏

7. Add 6 drops of thin CA to the center of all the hinges

on both the top and the bottom.

Do not use accelerator on any of the hinges. Do not glue

the hinges with anything but thin CA and do not attempt

to glue one half of the hinge at a time with medium or

thick CA. They will not be properly secured and the

controls could separate while the model is in flight.

❏

8. Join the rudder to the fin with the hinges and use

30-minute epoxy to simultaneously glue the tail gear wire in

the rudder and the tail gear bearing in the fuse. Do not

glue the nylon bearing to the rudder. Glue the hinges in

position with thin CA.

Hint: Apply a little petroleum jelly to the tail gear wire where

it passes through the nylon bearing. This will prevent the

wire from being glued into the bearing.

❏

9. Prepare the hinge slots in the ailerons the same way

you did for the tail surfaces.

❏

10. Use a toothpick to pack the torque rod holes in the

ailerons with 30-minute epoxy, then join the ailerons to the

wing with the hinges. Glue the hinges with thin CA. Wipe

away the epoxy that is squeezed out of the ailerons with a

paper towel and alcohol.

❏

11. If you have not yet installed and connected the

control horns and elevator, rudder and aileron pushrods

return to step 6 on page 32 for instructions on how to do so.

❏

1. Assemble the fuel tank per the manufacturers

instructions. Connect approximately 1' of fuel tubing to the

fuel pick-up fitting on the tank and 1' of fuel tubing to the

pressure fitting on the tank. Slide the tank through the

opening in F-2B as you route the lines through the holes

you drilled in the firewall (you may have to remove the

servos to install the fuel tank). Secure the tank to the tank

floor by hooking #64 rubber bands to the wood rails you

glued to the bottom of the tank floor.

❏

2. Install a 1" tail wheel with a 3/32" wheel collar.

❏

3. Install the wheels in the wheel pants (don't forget the

masking tape so the screw doesn't scratch the paint), then

mount the wheel pants to the landing gear. Secure the 8-32

nuts with a drop of thread lock.

❏

4. Mount the landing gear to the fuselage with the 8-32 x

3/4" SHCS and #8 washers.

❏

5. Install the elevator, rudder and throttle pushrods, then

install the control horns and hook them up the same way

you did earlier.

❏

6. Wrap the receiver and battery pack in at least 1/4" of

foam rubber, then fit them ahead of former F-2B in the

location shown on the plan. Pack extra foam in the

compartment to keep the receiver and battery pack from

dislodging during aerobatics or a rough landing.

❏

7. Mount the receiver switch in a convenient location that

will not interfere with the servos and pushrods inside

the fuselage.

Install the Hardware

THE CA WICKS

ALONG THE "TUNNELS"

TO THE ENTIRE

HINGE SURFACE

ASSEMBLE, THEN APPLY 6 DROPS

OF THIN CA TO CENTER

OF HINGE, ON BOTH SIDES

TEMPORARY PIN

TO KEEP HINGE

CENTERED

40