Balance the model (c.g.) – Great Planes Yak-55M 50-55cc Sport / 3D ARF - GPMA1230 User Manual

Page 28

28

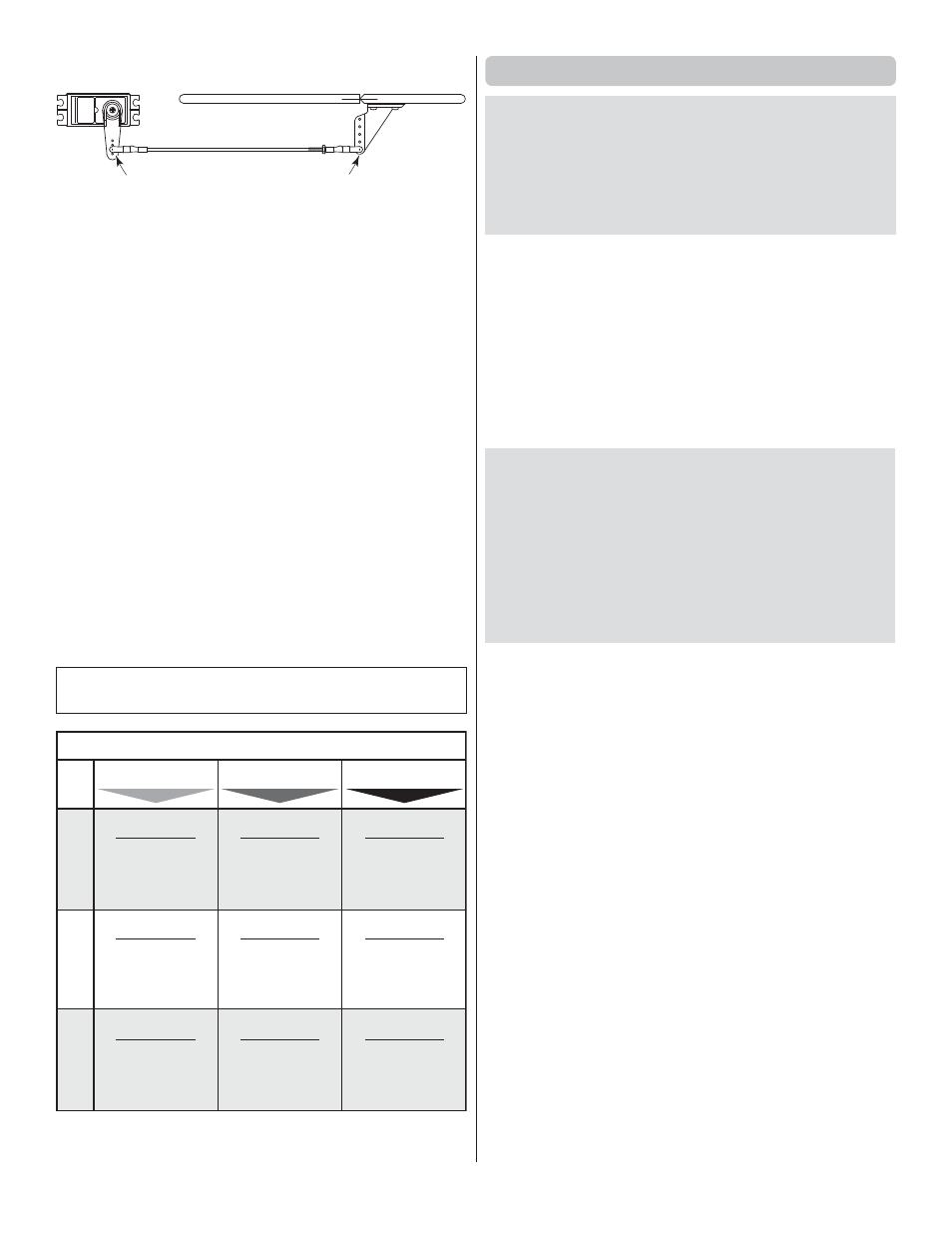

ACCEPTABLE PUSHROD HOOKUP

Move the pushrod farther out

on the servo arm…

…But leave the pushrod in the farthest out

location on the control horn.

If the optimum situation doesn’t provide enough control throw,

the pushrod may be moved inward on the control horn, but

it’s better to go

farther out

on the servo arm because this will

introduce less free play than the alternative. Only after moving

the pushrod all the way out on the servo arm, if you still can’t get

the throw required, you’ll have to resort to moving the pushrod

closer in on the control horn.

Note:

If you have a computer

radio, it is always desirable to set your ATVs to 100% (or as

near 100% as possible to achieve the control throw required).

If setting up a model that requires extraordinary control surface

throw (for 3D fl ying for example), start by “maxing-out” your

ATVs (typically 130% -- 140%). Then, the dual rates in your

“normal” fl ight mode will still be acceptably high (70% -- 80%)

for good servo resolution.

❏

4. Referring to the

Proper Pushrod Hookup

illustrations

above, adjust the location of the pushrod on the servo arm or on

the elevator horn and program the ATVs in your transmitter to

increase or decrease the throw according to the measurements

in the control throws chart.

❏

5. Measure and set the

low rate

elevator throws and the

high and low rate throws for the rest of the control surfaces

the same way.

NOTE

: The throws are measured at the

widest part

of the

elevators, rudder and ailerons.

These are the recommended control surface throws:

ELEV

A

T

OR

LOW RATE

3/4"

[19mm]

7°

Up & Down

3/4"

[19mm]

8°

Up & Down

4"

[102mm]

20°

Right & Left

R

UDDER

AILER

ONS

HIGH RATE

1-1/4"

[32mm]

12°

Up & Down

1-3/4"

[44mm]

19°

Up & Down

6"

[152mm]

42°

Right & Left

3D RATE

4"

[104mm]

42°

Up & Down

2-1/2"

[64mm]

27°

Up & Down

8"

[203mm]

63°

Right & Left

Balance the Model (C.G.)

More than any other factor, the C.G. (center of gravity/

balance point) can have the greatest effect on how a model

fl ies and could determine whether or not your fi rst fl ight will

be successful. If you value your model and wish to enjoy it

for many fl ights,

DO NOT OVERLOOK THIS IMPORTANT

PROCEDURE.

A model that is not properly balanced may

be unstable and possibly unfl yable.

At this stage the model should be in ready-to-fl y condition with

all

of the components in place including the complete radio

system, engine, muffl er, propeller, spinner and pilot. The fuel

tank should be empty.

❏

1. Use a fi ne-point felt tip pen to mark lines on the top of

wing on both sides of the fuselage 6.5" [165mm] back from

the leading edge. Apply narrow (1/16" [2mm]) strips of tape

over the lines so you will be able to feel them when lifting the

model with your fi ngers.

This is where your model should balance for the fi rst

fl ights. Later, you may experiment by shifting the C.G. 1/2"

[13mm] forward or 1/2" [13mm] back to change the fl ying

characteristics. Moving the C.G. forward will improve the

smoothness and stability, but the model will then be less

aerobatic (which may be fi ne for less-experienced pilots).

Moving the C.G. aft makes the model more maneuverable

and aerobatic for experienced pilots. In any case,

start at

the recommended balance point

and do not at any time

balance the model outside the specifi ed range.

❏

2. With the wing attached to the fuselage, all parts of the

model installed (ready to fl y) and an empty fuel tank, place

the model upside-down and lift it upside-down at the balance

point you marked.

❏

3. If the tail drops, the model is “tail heavy.” If possible, move

the battery pack and/or receiver forward to get the model to

balance. If the nose drops, the model is “nose heavy.” If possible,

move the battery pack and/or receiver aft. If needed, use Great

Planes “stick-on” lead (GPMQ4485). To fi nd out how much

weight is required, place incrementally increasing amounts

of weight on the fuselage over the location where it would be

mounted inside until the model balances. A good place to add

stick-on nose weight is to the fi rewall. Do not attach weight to

the cowl—this will cause the mounting screws to open up the

holes in the cowl. Once you have determined the amount of

weight required, it can be permanently attached. If required,

tail weight may be added by cutting open the bottom of the

fuse and gluing it permanently inside.

Note:

If mounting weight where it may be exposed to fuel

or exhaust, do not rely upon the adhesive on the back to

permanently hold it in place. Over time, fuel and exhaust

residue may soften the adhesive and cause the weight to fall

off. Instead, permanently attach the weight with glue or screws.