Set the control throws, Proper pushrod hookup – Great Planes Yak-55M 50-55cc Sport / 3D ARF - GPMA1230 User Manual

Page 27

27

GET THE MODEL READY TO FLY

Check the Control Directions

❏

1. Turn on the transmitter and receiver and center the trims.

If necessary, remove the servo arms from the servos and

reposition them so they are centered. Reinstall the screws

that hold on the servo arms.

❏

2. With the transmitter and receiver still on, check all the

control surfaces to see if they are centered. If necessary, adjust

the clevises on the pushrods to center the control surfaces.

FULL

THROTTLE

RUDDER

MOVES

RIGHT

ELEVATOR

MOVES DOWN

RIGHT AILERON

MOVES UP

LEFT AILERON

MOVES DOWN

4-CHANNEL RADIO SETUP

(STANDARD MODE 2)

❏

3. Make certain that the control surfaces and the carburetor

respond in the correct direction as shown in the diagram. If any

of the controls respond in the wrong direction, use the servo

reversing in the transmitter to reverse the servos connected to

those controls. Be certain the control surfaces have remained

centered. Adjust if necessary.

Set the Control Throws

To ensure a successful fi rst fl ight, set up your Yak-55M

according to the control throws specifi ed in this manual.

The throws have been determined through actual fl ight

testing and accurate record-keeping, allowing the model

to perform in the manner in which it was intended. If, after

you have become accustomed to the way the Yak-55M fl ies,

you would like to change the throws to suit your taste, that

is fi ne. However, too much control throw could make the

model too responsive and diffi cult to control, so remember,

“more is not always better.”

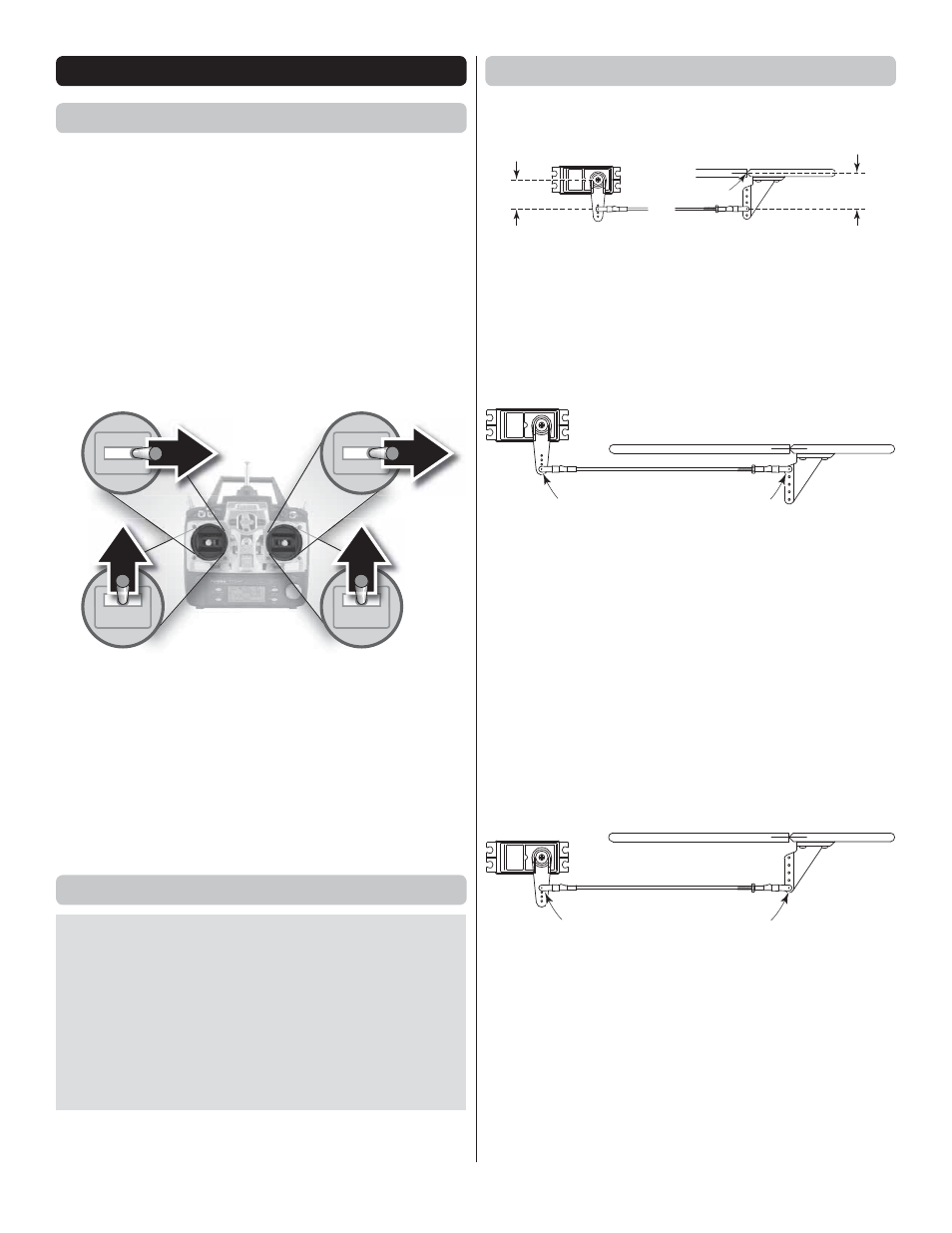

Proper Pushrod Hookup

AVOIDING FLUTTER, MAXIMIZING

SERVO OUTPUT TORQUE

Pivot point

CONTROL

HORN OFFSET

SERVO ARM

OFFSET

When connecting pushrods and setting up your control throws,

it is

critically important

to use proper pushrod geometry—

that is the distance from the pushrod on the servo arm to the

center of the output shaft (

servo arm offset

) compared to

the distance from the pushrod on the control horn to the pivot

point (

control horn offset

).

EXTREMELY DANGEROUS PUSHROD HOOKUP

Pushrod far out

on the servo arm…

…pushrod close in

on the control horn.

One particularly dangerous situation arises when the pushrod

on the servo arm is too “far out” and the pushrod on the control

horn is too “close in.” This setup is usually chosen by pilots

who are trying to achieve maximum, “monster” control throws

for 3D fl ight. But with your pushrods set up this way, any free

play (slop) in the linkages or servo will be greatly magnifi ed,

possibly causing destructive control surface fl utter. Additionally,

if you have to turn your ATVs way down for “normal” throw,

the result will be poor resolution and poor servo holding/

centering capabilities. More importantly, too much force may

be transmitted back to the servo, possibly causing control

surface blowback, stripped servo gears or stripped servo

arms—the latter two likely causing a crash.

PREFERRED PUSHROD HOOKUP

“Closest in”

on servo arm

“Farthest out”

on control horn

Here is an

optimum pushrod setup—the pushrod is “close

in” on the servo arm and “far out” on the control horn. This

situation gives the greatest mechanical advantage of the

servo over the control surface, which will increase the servo’s

centering capabilities and output torque, minimize any free

play in the system and allow high ATV settings for optimum

servo resolution and positive control “feel.”

Note:

When the

pushrod is “close in” on the servo arm, make certain the servo

arm can travel through its full range of movement without the

pushrod (or clevis or other type of connector) interfering with

the servo arm, output shaft or servo case.