Install the rudder, Install the rudder servos – Great Planes Yak-55M 50-55cc Sport / 3D ARF - GPMA1230 User Manual

Page 12

12

Install the Rudder

❏

1. Without using any

glue, install four hinges

into the holes in the

trailing edge of the

rudder

.

Note that the pivot point

of each hinge must align

with the center of the

trailing edge. To achieve

this alignment, the hinges

will be fairly deep in the fi n.

Also note that the hinges

must be perpendicular to

the leading edge.

❏

2. Again without glue,

test fi t the rudder to the fi n. Remove the rudder and all the

hinges. Add a small drop of oil to the pivot point on the hinges.

This will prevent the epoxy from adhering to the pivot point.

Make sure oil does not get on the gluing surface of the hinge.

If it does, clean the oil off with a paper towel square dampened

with denatured alcohol.

❏

3. Mix up approximately 1/4 oz. [7.4cc] of 30-minute epoxy.

Use a toothpick to thoroughly apply the epoxy in the holes in

the fi n and rudder. Use the toothpick to get the epoxy out of

the opening of the holes in the rudder and fi n so it doesn’t get

into the hinge pin. Wipe away any excess epoxy around the

outside of the holes with a couple of the small paper towel

squares dampened with denatured alcohol.

❏

4. Use the toothpick to apply epoxy to the ends of the rudder

hinges that go into the fi n. Insert each hinge into the fi n and

wipe away any excess epoxy that squeezes out of the hole.

❏

5. Apply epoxy to the other end of the hinges. Join the

rudder to the fi n, pushing the hinges only about 3/4 of the

way into the rudder. Use a toothpick to wipe away any epoxy

that squeezes out. Then fi t the rudder the rest of the way in.

❏

6. Move the rudder left and right to align the hinges. If

needed, use a length of masking tape to hold the rudder to

the fi n. Allow the glue to fully cure.

Install the Rudder Servos

We have designed this airplane with the option to use one servo

with 250 oz-in. of torque or to use two, lower strength servos

in tandem. If you are more of a sport fl yer and not an aspiring

3-D pilot, you can use a single servo with approximately 125

oz-in. You will need to make a decision on the number of

servos you will be using. Should you decide to use a single

servo and later decide you would like to use two servos you

can add the second servo later.

❏

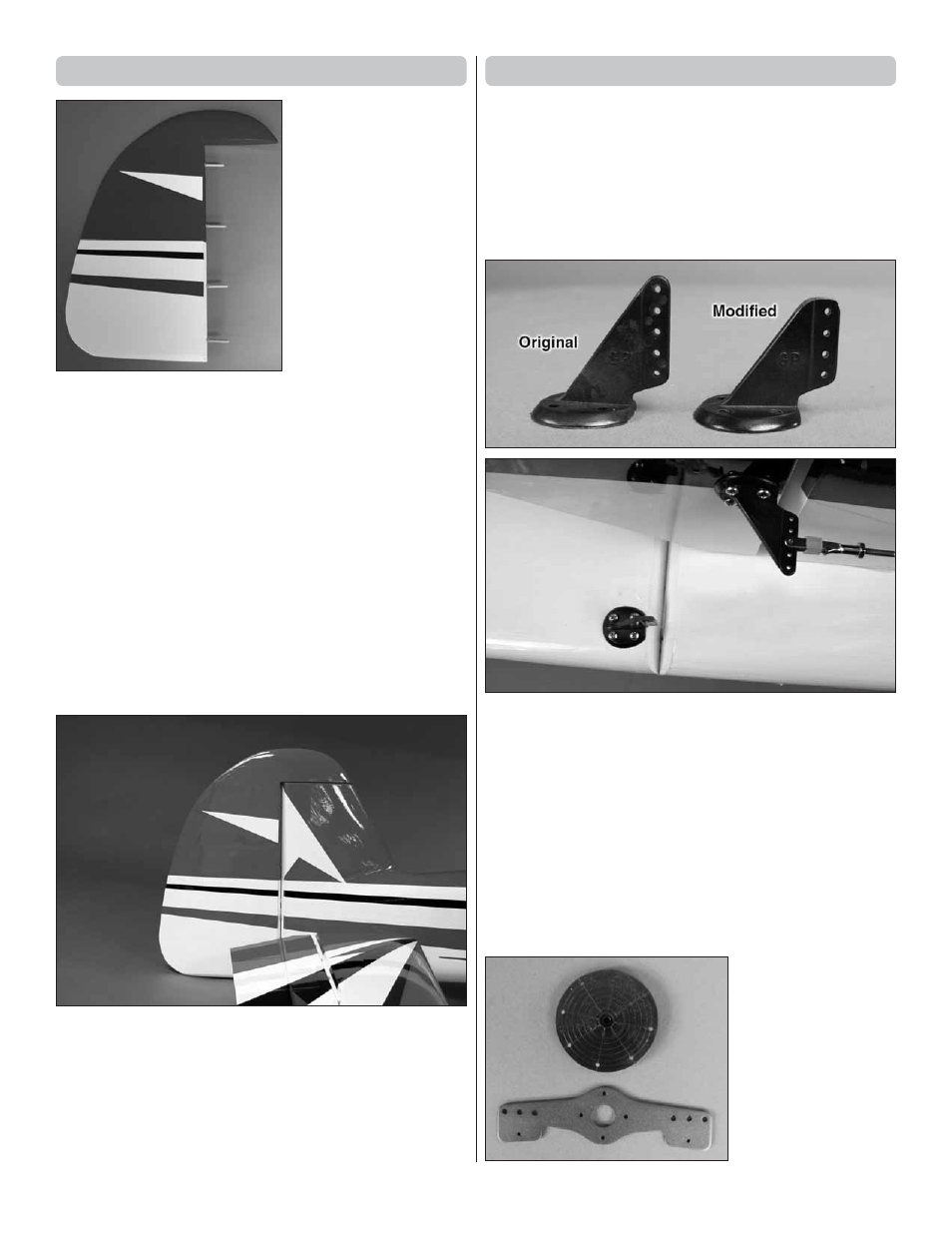

1. Modify two large black nylon control horns as shown.

This is easily completed with a high speed motor tool, small

belt sander or a sanding block with coarse sandpaper. As

you did with the ailerons horns, locate the plywood plate on

each side of the rudder. Position the horns over the plates.

Drill a 3/32" [2.4mm] hole through each of the holes in the

control horn. Drill only through the plywood plate. Do not

drill through the control surface.

Mount the horn with four

#4 x 1/2" [13mm] screws. Do this on both sides of the rudder.

SINGLE SERVO INSTALLATION

If you will be installing two servos, skip ahead to, “Two

Servo Installation”.

❏

❏

2. For the rudder

servo arm installation

you will need one of

the aluminum servo

arms included in the kit

and one of the round

servo disks included

with your radio system.

The round servo disk

needs to be at least 1"

[25mm] in diameter.