EVCO EC6295S201 User Manual

Page 5

Evco S.r

.l. • EC 6-295 P220 S201 • Sheet 3/3

“- - -” ) and “nEt” (slave alarm, it is a fixed indication) and the buzzer utters an intermit-

tent beep.

9

TECHNICAL DATA

9.1 Technical data

Box: self-extinguishing grey.

Size: 106 x 90 x 58 mm (4.17 x 3.54 x 2.28 in, 6 DIN modules).

Installation: on DIN rail (it is not supplied by the builder).

Frontal protection: IP 40.

Connections: screw terminal blocks with pitch 5 mm (0.19 in) for cables up to

2.5 mm² (0.38 sq in, power supply, inputs and outputs), 5 poles single line female

connector with pitch 2.5 mm (0.09 in, serial port).

Ambient temperature: from 0 to 55 °C (32 to 131 °F, 10 ... 90% of relative humidity

without condensate).

Power supply: 230 Vac, 50/60 Hz, 4 VA.

Clock data maintenance without power supply: 24 hours (the instrument must

have been ON for 2 min at least).

Alarm buzzer: included.

Measure inputs: 3 (cabinet, first and second evaporator probe) for PTC or NTC probes.

Digital inputs: 2 inputs: one multifunction input (NO or NC contact) and one lock

input, without voltage (they work with 5 mA).

Working range: from -50 to 99.9 °C (-58 to 212 °F) for PTC probe, from -40 to 99.9 °C

(-40 to 212 °F) for NTC probe.

Setpoint range: from -99 to 99.9 °C (-99 to 99 °F).

Resolution: 1 °F with unit of measure in Fahrenheit, 0.1 or 1 °C with unit of measure

in Celsius.

Display: one red LED 3-digit display 13.2 mm (0.51 in) high, compressor, evaporator

fan and cabinet light output status indicators, defrost status indicator, instrument mode

indicator.

Outputs: 5 relays: one 16 A @ 250 Vac relay for one 1½ HP @ 230 Vac compressor

control (NO contact), one 8 A @ 250 Vac relay for evaporator fan control (NO contact),

one 8 A @ 250 Vac relay for first defrost system control (change-over contact),

one 8 A @ 250 Vac relay for cabinet light control (NO contact) and one 8 A @ 250 Vac

relay for second defrost system control (change-over contact).

Kind of defrost: electric and hot gas defrost.

Defrost control: defrost interval, defrost end temperature, defrost maximum length

and defrost interval count mode (automatic, by hand and remote).

Serial port: TTL with EVCOBUS communication protocol, adapt for serial interface

EC IFC 02.

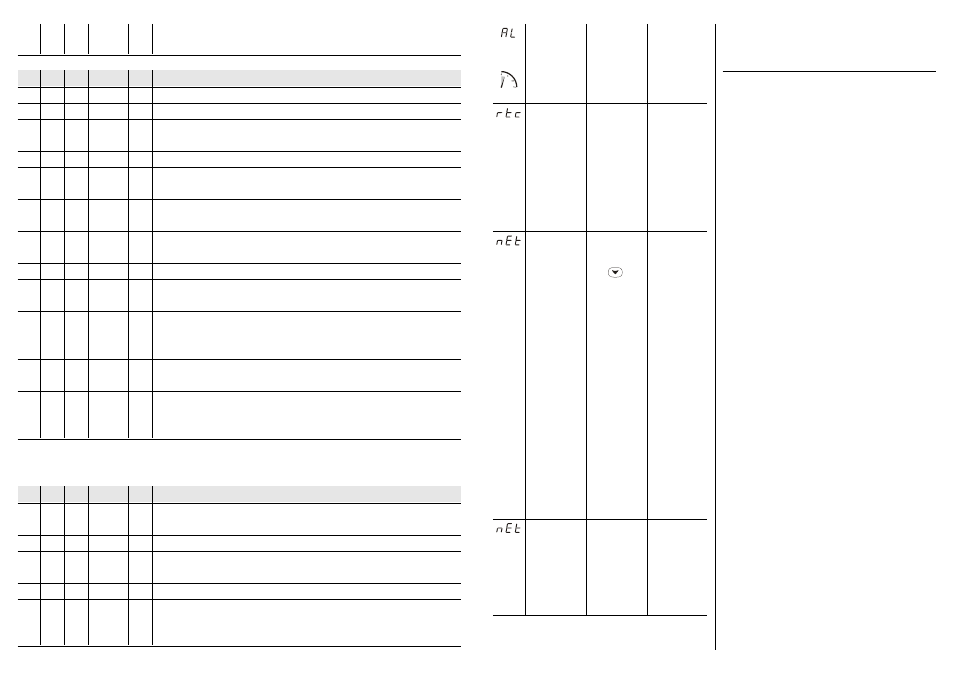

The instrument shows the indications above alternated with the cabinet temperature,

except the indication “E2“ (it flashes), “E0“ (it is alternated with the indication

for 3 s

every 4

real time

clock

alarm

slave

alarm

serial

network

alarm

there has been a lower

temperature alarm

there is the corruption

of the data of the clock

of the instrument

the instrument will be

set as slave, among

the remote controls,

coming from the mas-

ter, the slave has to

implement there will

be the compressor sta-

tus and there will be

one of the alarms you

saw in the previous

cases.

If the master is in the

STAND-BY mode and

the slave is ON, the in-

dication will be

showed every 2 s alter-

nated with the alarm

code

• the value of the pa-

rameters n0, n1 and

n3 is wrong

• the connections of

the instrument are

wrong

look at the parameters

A0, A1A, A2A, A8 and

A9

set the clock again

• if you have to show

the alarm code,

press

• look at the remedies

of that case

• look at the param-

eters n0, n1 and n3

• test the connections

of the instrument

no effects

• if the parameter dE

has value 3, the in-

strument will work

as if the parameter

had value 0

• the Energy Saving

cycle will never be

activated

look at the effects of

that case

the instrument will

work with the local

settings

dP

0

99

min

0

minimum time the compressor must have been ON at the moment of the defrost activation

in order that the defrost can be activated (it is important if d1 = 1)

(11)

LABEL MIN. MAX. U.M.

DEF. ALARMS

A0

0.1

15.0 °C/°F

(5)

2.0

hysteresis (differential, it is relative to A1A and A1b, it is important if A2A and/or A2b ≠ 0)

A1A

-99

99.9 °C/°F

(5)

-10

lower temperature alarm threshold; look at A2A as well

A2A

0

2

---

1

kind of lower temperature alarm (0 = it will never be activated, 1 = lower temperature alarm

relative to the working setpoint, 2 = absolute lower temperature alarm)

A1b

-99

99.9 °C/°F

(5)

10.0 upper temperature alarm threshold; look at A2b as well

A2b

0

2

---

1

kind of upper temperature alarm (0 = it will never be activated, 1 = upper temperature alarm

relative to the working setpoint, 2 = absolute upper temperature alarm)

A3

0

240

min

120

upper temperature alarm exclusion time since you turn the instrument ON (it is important if

A2b ≠ 0)

(12)

A5

-1

120

min

30

buzzer exclusion time since the multifunction input activation (it is important if i0 ≠ 0;

-1 = the buzzer will never be activated)

A6

0

240

min

5

temperature alarm exclusion time (it is important if A2A and/or A2b ≠ 0)

(13)

A7

0

240

min

15

upper temperature alarm exclusion time since the end of the after dripping evaporator fan

delay (since the end of F5, it is important if A2b ≠ 0)

(12)

A8

0

3

---

0

kind of temperature alarm the instrument has to store (it is important if A2A and/or A2b ≠ 0;

0 = it will never be stored, 1 = lower temperature alarm, 2 = upper temperature alarm,

3 = both the lower temperature alarm and the upper one)

A9

1

15

s

1

time between two records of the temperature alarm in succession (it is important if

A2A and/or A2b ≠ 0 and A8 ≠ 0)

AA

0

240

min

0

temperature alarms relative to the working setpoint exclusion time since the multifunction

input activation/deactivation (it is important if i0 = 6 or 7) and since the activation/end of the

Energy Saving cycle

LABEL MIN. MAX. U.M.

DEF. EVAPORATOR FAN

F1

-99

99.9 °C/°F

(5)

-1.0

evaporator fan stop temperature (first evaporator temperature, it is important if F7 = 3 or 4);

look at F6 as well

F2

0.1

15.0 °C/°F

(5)

2.0

hysteresis (differential, it is relative to F1, it is important if F7 = 3 or 4)

F4

0

2

---

0

evaporator fan action during the defrost and dripping (0 = it will be forced OFF,

1 = it will be forced ON, 2 = it will work in accordance with F7)

F5

0

15

min

2

after dripping evaporator fan delay

F6

0

1

---

0

kind of evaporator fan stop temperature (it is important if F7 = 3 or 4; 0 = absolute evapora-

tor fan stop temperature, 1 = evaporator fan stop temperature relative to the cabinet tem-

perature)

(14)