EVCO EV9323J9 User Manual

Page 4

Evco S.p.A. • Code 1049323E00 • page 4/5

14

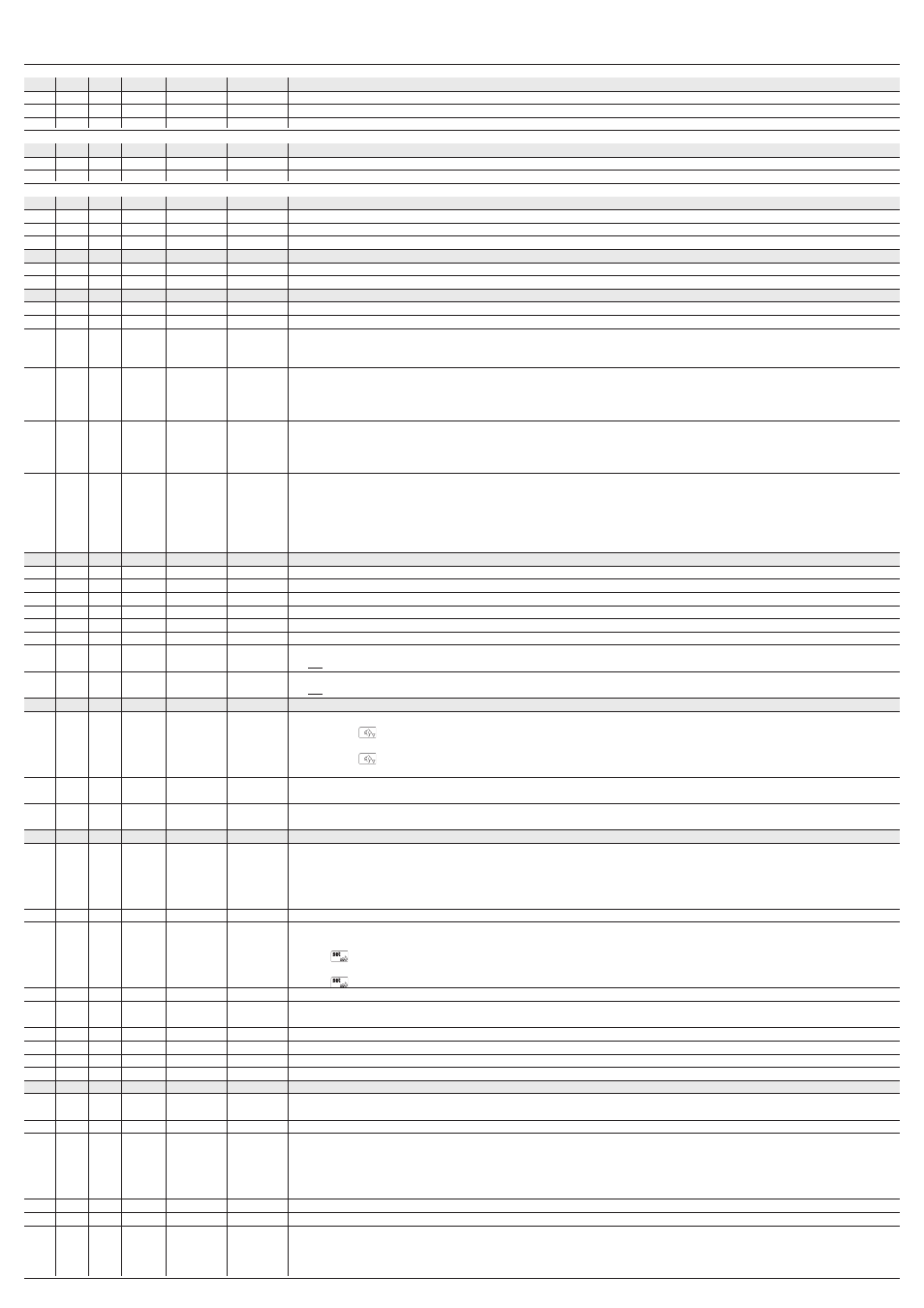

WORK SET-POINT, POWER DISTRIBUTED AND CONFIGURATION PARAMETERS

14.1 Work set-point

MIN.

MAX. U.M.

1 INPUT

2 INPUTS

r1

r2

°C/°F (1)

150

not visible

r1

r2

°C/°F (1)

not visible

150

r7

r8

°C/°F (1)

not visible

150

14.2 Power distributed

PARAM. MIN.

MAX. U.M.

1 INPUT

2 INPUTS

0

100

%

50

not visible

0

100

%

50

not visible

14.3 Configuration parameters

PARAM. MIN.

MAX. U.M.

1 INPUT

2 INPUTS

SP

r1

r2

°C/°F (1)

150

not visible

SP1

r1

r2

°C/°F (1)

not visible

150

SP2

r7

r8

°C/°F (1)

not visible

150

PARAM. MIN.

MAX. U.M.

1 INPUT

2 INPUTS

Po1

0

100

%

50

not visible

Po2

0

100

%

50

not visible

PARAM. MIN.

MAX. U.M.

1 INPUT

2 INPUTS

CA1

-25/-50 25/50 °C/°F (1)

0

0

CA2

-25/-50 25/50 °C/°F (1)

not visible

0

P0

0

1

- - - -

0

0

P2

0

1

- - - -

0

0

P5

0

(3)

- - - -

0

0

P6

0

(4)

- - - -

2

2

PARAM. MIN.

MAX. U.M.

1 INPUT

2 INPUTS

r0

1

99

°C/°F (1)

5

5

r1

0

r2

°C/°F (1)

50

50

r2

r1

999

°C/°F (1)

350

350

r6

1

99

°C/°F (1)

not visible

5

r7

0

r8

°C/°F (1)

not visible

50

r8

r7

999

°C/°F (1)

not visible

350

r12

0

1

- - - -

0

0

r14

0

1

- - - -

0

0

PARAM. MIN.

MAX. U.M.

1 INPUT

2 INPUTS

t0

0

1

- - - -

0

0

t1

0

250

s

1

1

t2

1

250

ds (5)

10

10

PARAM. MIN.

MAX. U.M.

1 INPUT

2 INPUTS

c0

0

2

- - - -

0

not visible

c1

1

999

s

80

not visible

c2

0

3

- - - -

1

not visible

c3

0

99

°C/°F (1)

10

not visible

c4

-1

120

s

15

15

c5

0

60

min

20

20

c6

0

60

min

20

20

c7

00:00 60:00 min:s

00:30

00:30

c9

0

120

s

10

10

PARAM. MIN.

MAX. U.M.

1 INPUT

2 INPUTS

A1

0

999

°C/°F (1)

0

0

A2

0

240

min

0

0

A3

0

2

- - - -

0

0

A4

0

999

°C/°F (1)

not visible

0

A5

0

240

min

not visible

0

A6

0

2

- - - -

not visible

0

WORK SET-POINT

work set-point

top set-point

floor set-point

POWER DISTRIBUTED

power distributed to the top (percentage of c1); see also c0 and c1

power distributed to the floor (percentage of c1); see also c0 and c1

WORK SET-POINT

work set-point

top set-point

floor set-point

POWER DISTRIBUTED

power distributed to the top (percentage of c1); see also c0 and c1

power distributed to the floor (percentage of c1); see also c0 and c1

MEASUREMENT INPUTS

with 1 measurement input, chamber probe inset; with 2 measurement inputs, top probe offset

floor probe offset

type of probe

0 = J

1 = K

temperature unit of measurement (2)

0 = °C

1 = °F

quantity shown by the upper part of the display during the on state or during normal functioning

0 = with 1 measurement input, chamber temperature; with 2 measurement inputs, top temperature

1 = with 1 measurement input, work set-point; with 2 measurement inputs, top set-point

2 = temperature of the floor

3 = floor set-point

quantity shown by the lower part of the display during the on state or during normal functioning

0 = with 1 measurement input, chamber temperature; with 2 measurement inputs, top temperature

1 = with 1 measurement input, work set-point; with 2 measurement inputs, top set-point

2 = value of the cooking timer or its count if the timer is active

3 = temperature of the floor

4 = floor set-point

MAIN REGULATOR

with 1 measurement input, work set-point differential; with 2 measurement inputs, top set-point differential

with 1 measurement input, minimum work set-point; with 2 measurement inputs, top minimum set-point

with 1 measurement input, maximum work set-point; with 2 measurement inputs, top maximum set-point

floor set-point differential

minimum floor set-point

maximum floor set-point

restraint between the top output and the cooking timer

1 = YES - the top output remains off if the cooking timer count is not in progress

restraint between the floor output and the cooking timer

1 = YES - the floor output remains off if the cooking timer count is not in progress

STEAM INJECTION

steam injection functioning mode

0 = pressing the

key causes the injection of steam for the time established with parameter t2 or for the entire duration that the key is pressed. The

parameter t1 establishes the minimum time that can pass between the two successive injections.

1 = pressing the

key enables automatic injection of the steam in cyclical mode (parameter t2 establishes the switch-on duration of the injector and

parameter t1 establishes switch-off duration)

if t0 = 0, minimum time that passes between two successive injections

if t0 = 1, injector switch-off duration

if t0 = 0, minimum injection duration

if t0 = 1, injector switch-on duration

VARIOUS

restraint between the power distributed to the top and power distributed to the floor

0 = no restraint

1 = the modification of the power supplied to an output automatically causes the supply of the maximum power to the other

2 = the modification of the power supplied to an output causes an automatic adaptation of the power supplied to the other such to guarantee that the

sum of the two percentages is always 100

cycle time for the top output and floor output switch-on, see also Po1 and Po2

event that causes the activation of the rapid heating function

0 = function cannot be activated

1 = press

for 1s (make sure that the instrument is in on state and that no procedure is in progress)

2 = pass from the stand-by state to the on state

3 = press

for 1s (make sure that the instrument is in on state and that no procedure is in progress) or pass from the stand-by state to the on state

temperature of the chamber over which the rapid heating function is interrupted (relative to the work set-point i.e. “work set-point - c3”)

duration of buzzer activation and of the acoustic output on conclusion of the cooking timer count; see also c9 (6) (7)

-1= the buzzer and the acoustic output must be deactivated in manual mode by pressing a key

time that passes between the activation of the airhole and the conclusion of the cooking timer count, see also c6

duration of the activation of the airhole at conclusion of the cooking timer count, see also c5

duration of the activation of the airhole in manual mode

time that passes between the activation of the buzzer and the acoustic output and the conclusion of the cooking timer count, see also c4

TEMPERATURE ALARMS

with 1 measurement input, temperature of the chamber above which the chamber temperature alarm is activated; with 2 measurement inputs, tempera-

ture of the top above which the top temperature alarm is activated; see also A3 (8)

with 1 measurement input, chamber temperature alarm delay; with 2 measurement inputs, top temperature alarm delay

with 1 measurement input, type of chamber temperature alarm delay; with 2 measurement inputs, type of top temperature alarm delay

0 = no alarm

1 = absolute (i.e. A1)

2 = with 1 measurement input, relative to the work set-point (i.e. “work set-point + A1”); with 2 measurement inputs, relative to the top set-point (i.e. “top

set-point + A1”)

floor temperature above which the floor temperature alarm is activated, see also A6 (8)

floor temperature alarm delay

type of floor temperature alarm

0 = no alarm

1 = absolute (i.e. A4)

2 = relative to the floor set-point (i.e. “floor set-point + A4”)