Ep grease – Crosman BPE3571 User Manual

Page 9

9

o Pull the trigger

• You and others with you should always wear shooting glasses to protect your eyes.

• Do not shoot at hard surfaces or at the surface of water. The bullets may bounce off or

ricochet and hit someone or something you had not intended to hit.

• Always choose your target carefully. It is best to only shoot at paper bulls eye targets that

are attached to a safe backstop made of an energy absorbing material like dirt or sand.

• Your airgun is designed for target shooting and hunting and is suited for outdoor use

only. Always remember to place your target carefully. THINK about what you will hit if

you miss the target.

12. Removing a Jammed Bullet

A jammed bullet is usually the result of trying to fire the airgun when the pressure is too

low (less than 1000psi). Alternatively, the airgun may jam if the EPIC™ controls are set

too low for the grain weight of the bullet in the chamber. Before firing the airgun make

certain there is sufficient pressure for proper operation. Make sure the gauge is indicat-

ing a pressure between 1000 psi (69 Bar) and 3000 psi (207 Bar).

If the bolt can be moved from the rearward “READY TO FIRE” position, to the forward

“Not Ready to Fire” position you can remove a jammed bullet using the Electronic De-

pressurization Method for discharging the bullet with air pressure (See Section 7). To use

this method the airgun must have greater than 2000 psi in the reservoir.

How to Electronically Depressurize the Airgun

• Move the cross block safety to “ON SAFE”.

• Keep the airgun pointed in a SAFE DIRECTION.

• Remove the clip.

• Close the bolt by moving it forward and then downward into the “NOT READY TO

FIRE” position.

• Rotate the bolt activation lever so the word, “DISABLED,” is visible to prevent the

bolt from moving. (See Section 3)

• Set the mode to “Disch”. (See Section 5)

• Rotate the bolt activation lever so the word, “ACTIVE,” is visible to allow movement

of the bolt handle. (See Section 3)

• Move bolt handle rearward to the “READY TO FIRE” position.

• Move the cross block safety to “OFF SAFE”.

• Keep the airgun pointed in a SAFE DIRECTION.

• Pull the trigger.

• Check your pressure on the LCD screen.

• You can repeat firing the airgun until the pressure goes to 1000 PSI.

• If your unable to move the bolt from the rearward “READY TO FIRE” position to the

forward “NOT READY TO FIRE” position wait 1 hour, if possible, and try again.

• If you are unable to discharge the jammed bullet using this method, follow the steps

below to remove a jammed bullet using a Ramrod.

Use of a Ramrod

DO NOT ATTEMPT THIS PROCEDURE ON A PRESSUR-

IZED AIRGUN. You must depressurize your airgun first. In this procedure, you

will put a cleaning rod down the barrel of the airgun. While you are performing this

procedure, it is extremely important to you make sure the cross block safety is

“ON SAFE”, the bolt remains in the open position and you keep your finger away

from the trigger. Failure to follow these instructions may cause the jammed bullet

and ramrod to propel out of the barrel and may result in serious injury or death.

Follow these instructions:

• Keep the safety “ON SAFE.”

• Point and keep the airgun pointed in a SAFE DIRECTION.

• Move the bolt out of the “READY TO FIRE POSITION” and rotate the bolt acti-

vation lever so the word “DISABLED” is visible, preventing the bolt

from moving.

• Remove the 6 round clip or single shot tray.

• Locate the opening at the front of the trigger guard and the set screw inside

the opening. Insert .125 allen wrench into opening and slightly turn the set

screw counter clockwise until you hear the airgun begin to vent though the

vent port

• After completely venting the airgun, turn the set screw clockwise 1/8 turn to

seal the vent.

• Check the EPiC™ display to make certain there is no air pressure remaining in

the airgun. (See Section 5C)

• Rotate the bolt activation lever so the word, “ACTIVE,” is visible and move the

bolt upward and then rearward to open it fully.

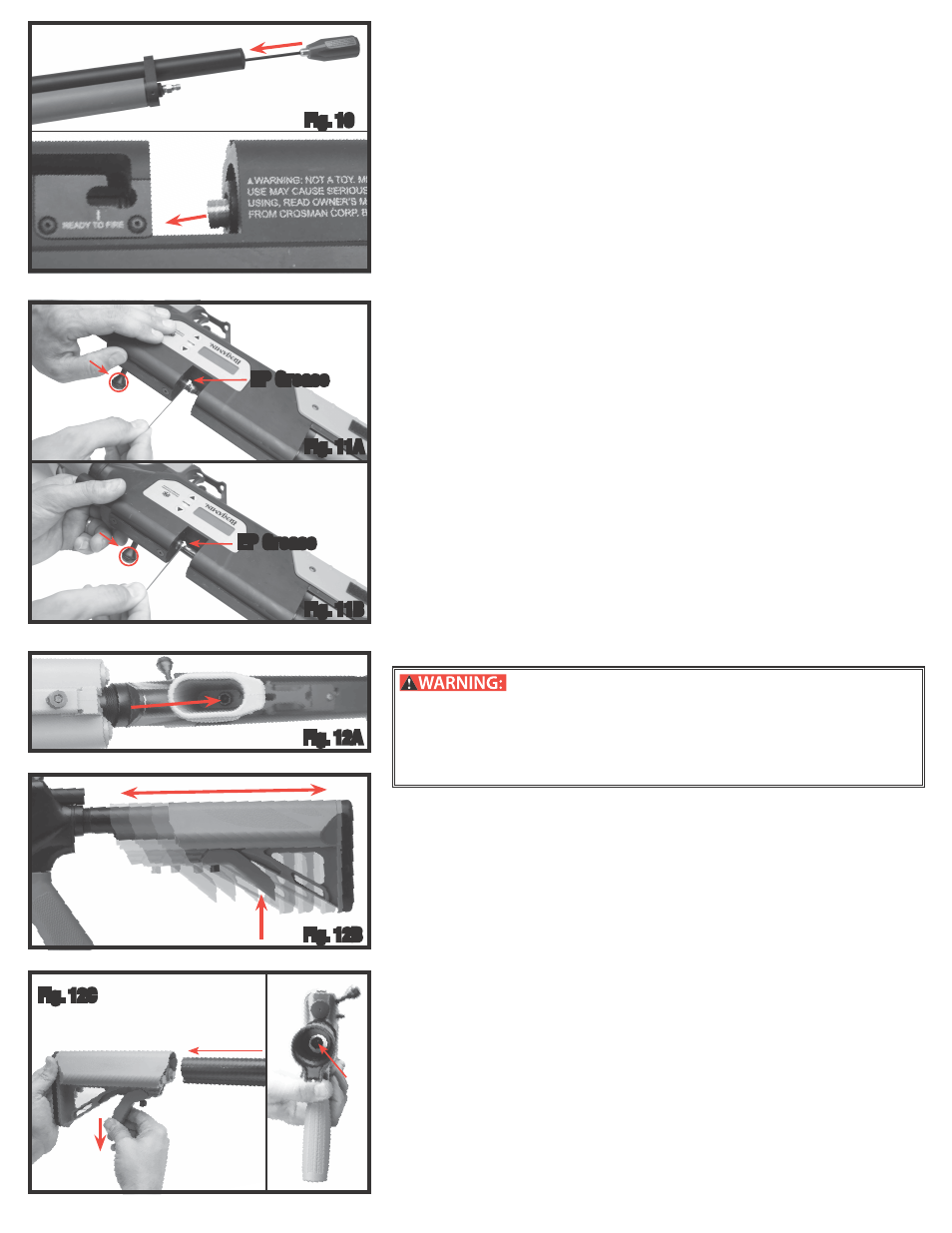

• Insert a ramrod of the proper size into the muzzle (Fig. 10). The barrel could

be damaged if you use a ramrod that is not the proper size for a .357 caliber

airgun and the proper length for this barrel.

• Use the ramrod to push the bullet into the bullet loading port (forward of the

bolt tip). The bolt must be fully open (rearward) for the jammed bullet to clear

the breech when it is pushed out by the ramrod.

• Remove and discard the bullet. Do not reuse the bullet.

• Remove the ramrod, keeping the airgun pointed in a SAFE DIRECTION.

• Close the bolt.

• If you are not able to unjam your airgun by following this procedure, take no

further action. Crosman Corporation or an Authorized Service Station will

unjam your airgun at no cost during the warranty period).

Fig. 10

Fig. 12A

Fig. 12B

Fig. 12C

Fig. 11A

Fig. 11B

EP Grease

EP Grease