Nosler is the registered trademark of nosler inc – Crosman BPE3571 User Manual

Page 12

12

• Your backstop should be checked for wear before and after

each use. All backstops are subject to wear and will eventually

fail. Replace your backstop if the surface is worn or damaged

or if a ricochet occurs.

•

DO NOT attempt to disassemble or tamper with your airgun.

Use an Authorized Service Station. Using unauthorized repair

centers or modifying the function of your airgun in any way

may be unsafe and will void your warranty.

• Store airgun in a secure location.

• Before you store your airgun, remove the clip, make sure there

is no bullet in the chamber (See Section 10).

• Store this airgun charged with pressure to keep the valves

closed against dirt.

• Whenever you store the airgun, make sure it is “ON SAFE”

(See Section 2A).

This airgun has been classified as an adult airgun and is recommended for

adult use only. Because it is considered to be a special-purpose airgun, it is

exempt from specific types of trigger pull, safety mechanism and drop tests.

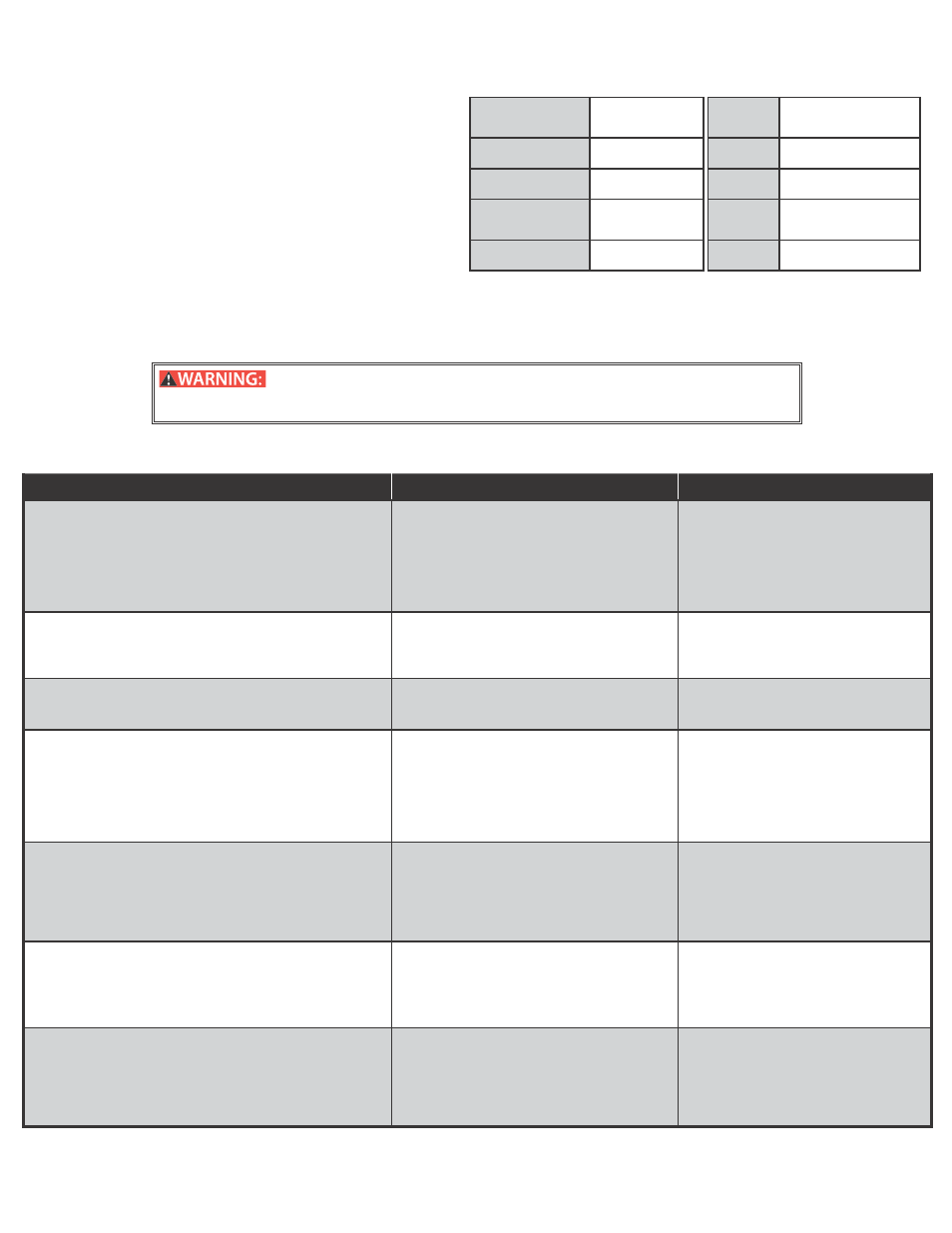

SPECIFICATIONS

Mechanism

Electronic and

Pneumatic

Length

48 inches

Capacity

330 cc

Barrel

25 in.

Power source

HPA

Safety

Trigger cross-block

Caliber/

Ammunition

.357 Cal.

Velocity Up to 1000 FPS

Weight

9.5lbs

FPE

75 to 200

Nosler is the registered trademark of Nosler Inc.

Appendix A

Error Message

Meaning

Suggested Action

MSG1: CRITICAL HALT TRIGGER ERROR

MSG2: (none)

1. The pre-trigger or trigger switch was acti-

vated when the bolt was moved into the fire

position.

OR

2. The pre-trigger or trigger switch has failed.

1. Ensure that the trigger is not being

depressed at all.

2. Return the airgun to Crosman Corp.

for analysis and repair.

MSG1: CRITICAL HALT

MSG2: TRIGGER SW2 PROBLEM 1

The trigger switch has failed, making the unit

inoperable.

Return the airgun to Crosman Corp. for

analysis and repair. As an added precau-

tion, refrain from placing the bolt into

the fire position.

MSG1: CRITICAL HALT NO BULLET LOAD

MSG2: BULLET NOT CHAMBERED

The pre-trigger or trigger was engaged before

the bolt was moved out of the fire position.

After every shot, the bolt must be

cycled.

MSG1: CRITICAL HALT VERY HIGH PSI

MSG2: MANUALLY VENT THE TANK

1. The pressure in the tank is too high to

safely fire a round.

OR

2. The pressure sensor in the airgun

has failed.

1. Manually vent the tank to a pressure

below 3200PSI before proceeding.

Follow Depressurizing procedure in

Section 7B.

Return the airgun to Crosman Corp. for

analysis and repair.

MSG1: CRITICAL HALT VERY LOW PSI

MSG2: REFILL THE TANK

1. The pressure in the tank is too low to safely

fire a round.

OR

2. The pressure sensor in the airgun has

failed.

1. Refill the tank to a safe level before

proceeding. (See Section 6)

2. Return the airgun to Crosman Corp.

for analysis and repair.

MSG1: “CRITICAL HALT BATTERY LOW”

MSG2: “REMOVE AND REPLACE THE BATTERIES”

The battery level is below a safe operating

threshold

1. Replace the batteries with 2 AA Size.

MSG1: BATTERY WARNING REPLACE SOON

MSG2: FEWER THAN 3 SHOTS REMAIN

1. The battery voltage is approaching a limit

that may produce inconsistent shots.

OR

2. The connection from the battery holder to

the circuit board has been compromised.

1. Replace the batteries with 2 AA size.

Lithium batteries are recommended.

2. Return the airgun to Crosman Corp.

for analysis and repair.

Explosion Danger. Do not attempt to ship a pressurized airgun. Always completely

depressurize this airgun before shipping by any means. Failure to follow these instructions may result

in serious injury or death.