Press and hold for backlight, Fig. 6h – Crosman BPE3571 User Manual

Page 7

7

6. Pressurizing the Airgun

Your new airgun is unique because it operates on compressed air or N

2

. This owner’s

manual describes operating the airgun with compressed air and N

2

only.

CAUTION: Use of CO

2

liquid or gas will damage the valve and void your warranty.

This airgun is designed for use at pressures between 1,000 psi (69 Bar) and 3,000 psi (207

Bar) depending on how you, as the user, adjust (tune) the airgun to work.

Explosion Danger. Use only compressed air or N

2

in this airgun.

Use of other gasses, including oxygen, can cause a fire or explosion may result in

serious injury or death.

Do not disconnect the fill hose before first bleeding the air. Fail-

ure to follow these instructions may cause the hose to whip from pressure built up

in the fill hose and may result in serious injury or death.

DO NOT FILL AT A RATE GREATER THAN 1000 PSI (69 BAR) PER MINUTE.

CAUTION: It is important to fill the pressure reservoir slowly when filling from a low

pressure (from 0 psi). Filling too rapidly will over pressurize the airgun’s low pressure

system and may damage the regulator and/or electrical control valve.

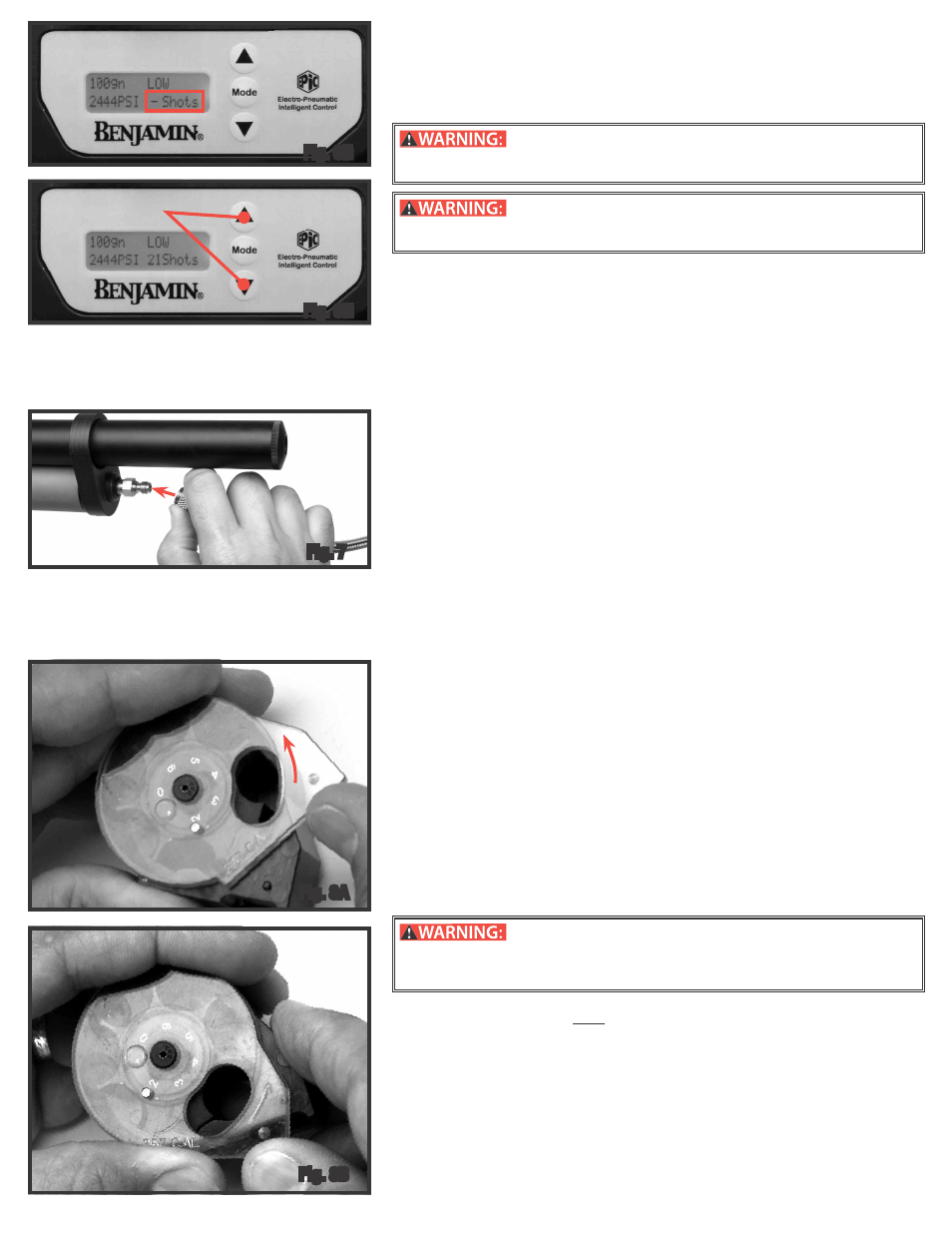

A. Pressurizing (Filling) the Airgun with a High Pressure Tank

Airgun may be filled from a high pressure tank (bottle) like the Benjamin HBP45K. Scuba

tanks can also be utilized for the task. For scuba tank use go to Crosman.com to select

the correct adapter.

• Be sure to wear eye protection.

• Make sure the airgun is unloaded and not cocked. (See Section 10 for instructions

on unloading)

• Read all instructions with your tank so you are familiar with its operation. Review

EPiC™ operation (Section 5) to view the airgun reservoir pressure.

• Put the airgun “ON SAFE” (See Section 2A).

• Point the airgun in a SAFE DIRECTION.

• Remove the cap that covers the fill nipple on the airgun.

• Connect the quick-disconnect fitting on the adaptor’s hose to the fill nipple

(Fig. 7).

• Slowly open the valve on your tank and start filling the airgun SLOWLY. Filling too

quickly will cause heat buildup that can affect accuracy of the fill pressure.

• Watch the gauges on the airgun and your tank (if equipped) until the desired pres-

sure is reached (1000-3000 psi).

• DO NOT fill the airgun to more than 3000 psi. See “Overfill” information below.

• Turn the valve on your tank off when the desired fill pressure is reached.

• BLEED the fill hose COMPLETELY to avoid hose whip from pressure in the fill hose.

• Disconnect the tank’s fill hose from the fill nipple on the airgun.

• Replace the cap over the fill nipple and tighten. Always keep the fill nipple capped to

eliminate the possibility of dirt entering the check valve.

• If the airgun shows the Critical Halt for Low PSI then the airgun can be refilled with a

bullet in the barrel. First you must open the bolt to the most rearward position before

refilling the reservoir to a pressure greater than 1000psi.

Note: the airgun will be ready to fire at any pressure above 1000psi.

B. AVOID PRESSURE OVERFILL

• Overfilling 3000psi fill pressure does not improve performance. If you discover that

the airgun has been overfilled, try to dry fire the airgun (cock and shoot without bullet

loaded) in a SAFE DIRECTION until pressure on your airgun drops to 3,000 psi.

• If the airgun will not discharge air with each shot, the valve may be completely pres-

sure locked and will require use of the degassing procedure of your airgun. Follow

the instructions for how to degas your airgun (See Section 7) using the .125 allen

wrench included with your airgun.

7. Depressurizing the Airgun

To depressurizing your airgun (e.g., for service) utilize the following methods:

A. Manual Depressurizing Method

Performing the following procedure may exhaust air from the

barrel at a high rate and fire a bullet from the airgun if one is in the barrel. There-

fore, make certain the airgun is pointed in a SAFE DIRECTION. Failure to follow

these instructions may result in serious injury or death.

• Keep the airgun pointed in a SAFE DIRECTION.

• Make certain the airgun is

NOT in the “READY TO FIRE” position by:

o Moving the cross block safety to “ON SAFE”.

o Remove the clip.

o Closing the bolt by moving it forward and then downward.

o Moving the bolt activation lever so the word, “DISABLED,” is visible to prevent

movement of the bolt. (See Section 3)

• Locate the opening at the front of the trigger housing. Insert a .125 in. allen wrench.

• Turn the set screw 1/8 turn counter clockwise.

• You should hear the pressure vent through the vent port.

• When venting is complete, turn the set screw 1/8 turn clockwise to seal the vent.

• Check the EPiC Display to make certain all pressure (PSI) has been relieved from the

airgun. See Section 5C for viewing gauge information.

Fig. 6H

Press and Hold

for Backlight

Fig. 6F

Fig. 6G

Fig. 7

Fig. 8A

Fig. 8B