23. calibration, 25. equipment preparation, 27. reference adjust – Fluke 2180A User Manual

Page 34: 29. reference adjust (+v), 31. zero adjust, Calibration -4, Equipment preparation -4, Reference adjust -4, Reference adjust (+v) -4, Zero adjust -4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

2180A

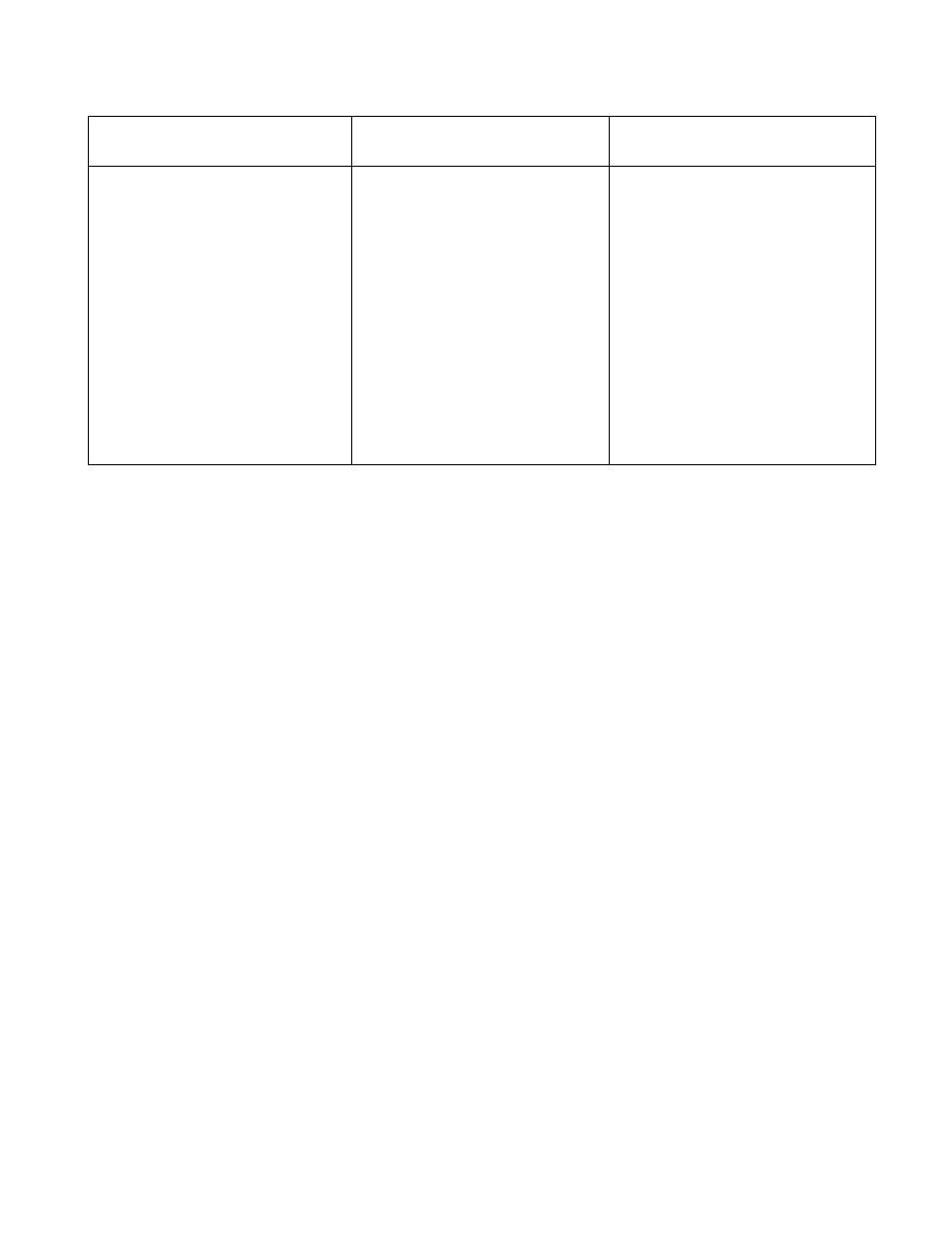

Table 4-2. Recommended Test Equipment

TEST EQUIPMENT

MINIMUM USE

SPECIFICATIONS

RECOMMENDED

MODEL

Variable Line-Voltage

Transformer

100,120, 220, 240V ac, as required,

±10%

General Radio VARIAC W5HM

Decade Resistance Box

.01Ì2 resolution

General Radio 1433T,

ESI Model RS925A, or

equivalent

Voltage Divider

100:1

Fluke Y2022 or equivalent

Calibrator (DC Source)

10

m

V resolution

Fluke 343A or equivalent

Digital Voltmeter (±100

m

V)

100

m

V resolution, on 10V range

Fluke 8800A or equivalent

Lag Bath

Temperature Stable, .01° resolution

Customer Constructed. (See Lag

Bath Construction, this section)

4-23. CALIBRATION

4-24. The thermometer should be calibrated at either

90-day or annual periods, depending upon the accuracy

desired, and any time that repairs are made to the

instrument. Conversion between Fahrenheit and Celsius

scales is realized through a mathematical computation by

the microcomputer. Calibration in °F is recommended.

Calibration in either scale (° F or °C) insures the accuracy

of the other. Either scale can be verified by executing the

Performance Test.

4-25. Equipment Preparation

4-26. Prepare the equipment for calibration using the

following procedure:

1. Remove the top cover from the instrument.

2. Apply power to 2180A and all test equipment to

be used. Insure the 2180A warm-up period has been

sufficient to reach rated accuracy (at least 20 minutes).

3.

Select the desired temperature scale (°C or °F).

If the Limits Option is installed select the LIMITS

or >) function.

NOTE

Before removing the RTD Input Module,

power switch to OFF.

set

CAUTION

Do not connect analog common (OV) to digital

common (-15V with respect to analog

common). Instrument damage may result.

4-27. Reference Adjust

4-28. Perform Reference Adjust using the following

procedure:

1.

Connect the DVM between TP 16 and TPl

(Analog Common).

2. Adjust R7 for a reading of 6.2V ±100

pN.

4-29. Reference Adjust (+V)

4-30. Perform the Reference Adjust for the ±V using

the following procedure:

1. Connect the DVM to TP 17 (HI) and TPl (LO -

Analog Common).

2.

Adjust R44 to obtain a reading of 6.2V ±100

m

V.

4-31. Zero Adjust

4-32. Perform the Zero Adjust using the following

procedure:

1.

Connect the 2180A Digital Thermometer, DC

Voltage Calibrator, and Voltage Divider as

illustrated in Figure 4-3.

2.

On the RTD Input Module, place a jumper

between -V and -S on TBl. Select AUTO (S2 on

the Input PCB).

4-4