Kenmore 385.15358 User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SEWING

machíne

DIV. 20

MODEL 384. 15358

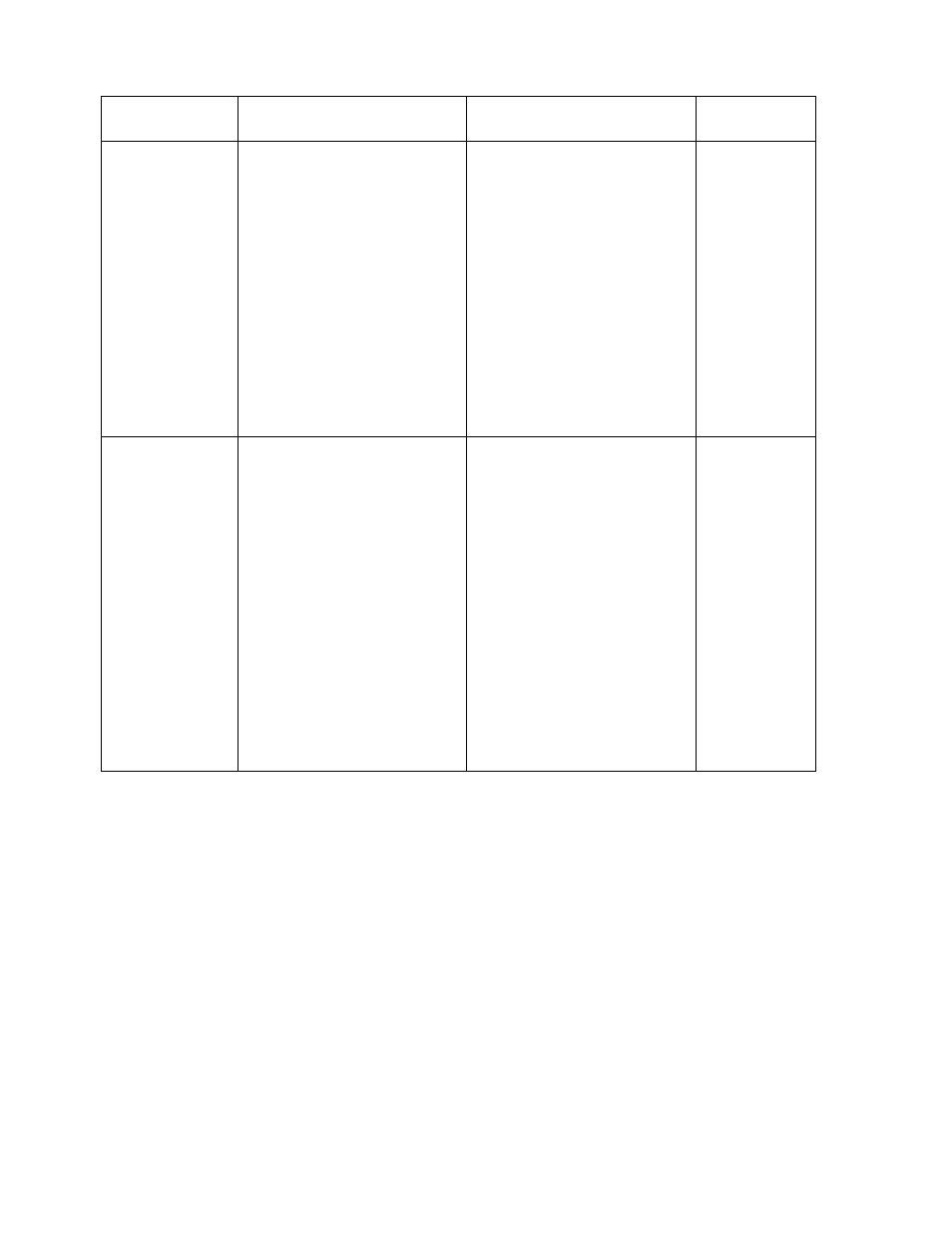

CONDITION

CAUSE

HOW TO FIX

REFERENCE

6. NOISY

OPERATION

1. BACKLASH BETWEEN

SHUTTLE HOOK GEAR AND

LOWER SHAFT GEAR IS TOO

GREAT.

SEE MECHANICAL

ADJUSTMENT "CLEARANCE

BETWEEN NEEDLE AND HOOK

(N0.2)”.

P.17

2. LOWER SHAFT GEAR IS

LOOSE.

ELIMINATE THE LOOSENESS.

3. INAPPROPRIATE BELT

TENSION.

4. UPPER SHAFT GEAR IS LOOSE.

SEE MECHANICAL

ADJUSTMENT “MOTOR BELT

TENSION”.

ELIMINATE THE LOOSENESS.

P.26

5. NOT ENOUGH OIL.

OIL ALL MOVING PARTS.

7. DEFORMATION

PATTERN

1. INAPPROPRIATE ZIGZAG

SYNCHRONIZATION.

SEE MECHANICAL

ADJUSTMENT“NEEDLE

SWING”.

P.14

2. INAPPROPRIATE

DISENGAGEMENT OF CAM

FOLLOWER.

SEE MECHANICAL

ADJUSTM

“DISENGAGEMENT OF CAM

FOLLOWER”.

P.24

3. UPPER THREAD TENSION

IS TOO STRONG.

ADJUST UPPER THREAD

TENSION CORRECTLY.

P.11