C&D Technologies RS-1476 Standby Battery Vented Cell User Manual

Page 9

SECTION 4 - INSTALLING CELLS*

* These instructions apply to lead acid batteries configured as single cell

containers or multi-cell containers. The term containers can apply to both

configurations.

NOTE: Read and follow the “Battery Handling and Installation

Guidelines” packed on top of the cells, form RS-999

4.1 Unpacking and handling containers

Do not handle or move units without the orange shipping vent installed.

Before installing battery, gather the following tools and equipment.

1.

Safety equipment: Eye protection and portable or stationary water

facilities for rinsing eyes and skin in the event of contact with electrolyte,

safety shoes, rubber apron, and acid resistant gloves

2. Insulated

inch-pound torque wrench and box wrench

3. Optional thermostatically controlled hot plate with no open flames

4. Sodium bicarbonate, water, a bucket, and clean rags.

DO NOT USE

SOLVENTS of any kind, other than water.

5. One inch paint brush or rag for applying NO-OX-ID grease

6. Brass bristle brush(s), packed with battery accessories, optional:

fiber bristle brush, burlap cloth, or medium grade Scotch Brite™

7. Cell lifting strap/spreader block (when provided)

8. Battery hoist of appropriate lifting capacity

9. Platform lift, when applicable

10. Hot air gun or blower (optional)

Large single cell and multi-cell containers are packed in individual cartons

strapped to a wooden pallet. Remove the straps and carefully lift off

cartons for access to lifting slots in the bottom support piece. (Figure 1.4.1)

Always lift units from the bottom,

never by the posts. A lifting sling and

spreader board are packed in the accessories carton. Slip the lifting sling

under the cell, then install the spreader block on top of the cell. Ensure that

sling fits in notches in the spreader board. Use the loops in the sling to hoist

the unit. Refer to Figure 1.4.2.

Smaller units, such as the D sizes, are supplied in cartons from which they

can be lifted by hand.

4.2 Pre-installation procedures

At the first opportunity, check the electrolyte level in each cell. It should be

between the high and low level lines (see Figure 1.4.3) on the container. If

the level is below the top of the plates, order a new cell and file a claim for

concealed damage against the carrier.

If the cell plates are covered but the level is lower than the low level mark,

make no additions (i.e. D.I. water) until the cells have been on float charge for

one week, and contact your local C&D representative. If electrolyte is found on

the top of the cell or terminal posts, clean immediately with a solution consisting

of one pound sodium bicarbonate to one gallon of water. Do not allow the

cleaning solution to enter cell. Rinse with clean water after neutralization step.

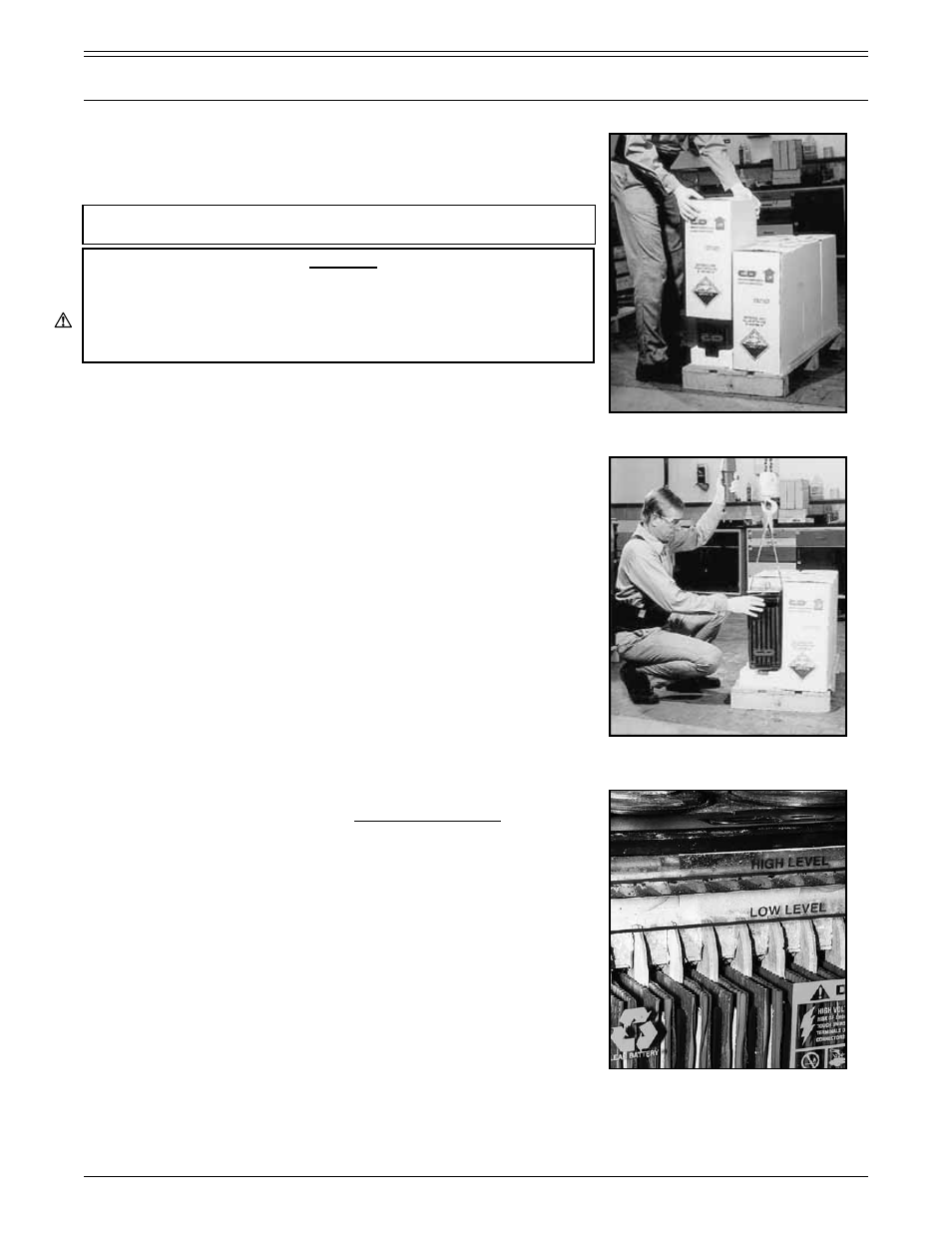

FIGURE 1.4.1 - Removing the cartons

FIGURE 1.4.2 - Use of lifting sling and

spreader board

FIGURE 1.4.3 - Electrolyte should be

between the high and low level lines

PART 1

RECEIVING AND INSTALLATION (CONTINUED)

CAUTION

Before working on the battery, be sure to discharge static electricity that

can build up on tools, cell containers or the technician by touching a

grounded surface in the vicinity of the battery but far enough from the cells

and flame arrestors to avoid creating sparks. Do not expose cells to open

flames that could ignite the gases produced by a charging battery.

RS1476/0215/CD

7

www.cdtechno.com