C&D Technologies RS-1476 Standby Battery Vented Cell User Manual

Page 11

WARNING

Do not use wire pulling compounds, oils, grease or any other material not

specifically authorized by C&D in writing, as these may contain additives

that could damage the plastic containers. Use of any unauthorized solvents

voids warranty.

For seismic (EP) racks, spacers between cells are required.

Add front and end restraining rails and install front-to-back restraining rail tie rods if

supplied, for EP racks. End rails should be placed within one-eighth-inch from end

cells. Reference “Rack Instructions” for more information. Do not tighten end rails

against cells as it can result in jar damage. Tighten tie rods/cell restraining rails to

allow a business card to fit between the cell jar and the restraining rail.

CAUTION

Never move or adjust a rack with batteries loaded on it.

After cells have been installed and connected, remove the orange shipping

vents and install the flame arrestors and dust cover vent assemblies provided in the

accessory kit.

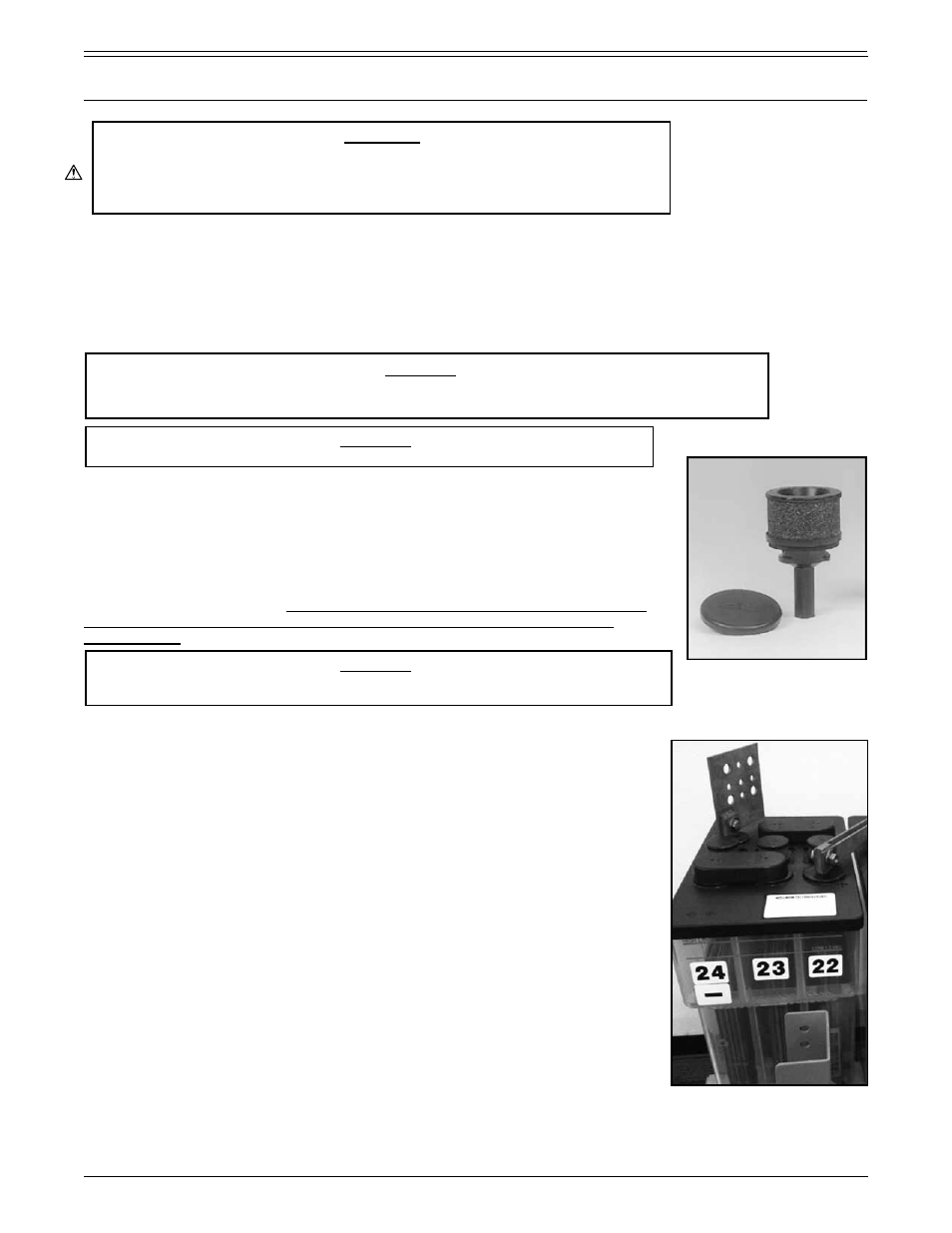

4.4 Flame arrestors

All C&D standby cells use flame arrestors, see Figure 1.4.4. Most cells are shipped

with orange colored vent plugs which must be removed and discarded before

installing the flame arrestors. DRY-CHARGED CELLS MUST BE STORED WITH

ORANGE VENT CAPS AND PLASTIC FILM IN PLACE UNTIL READY FOR

ACTIVATION.

CAUTION

Be sure flame arrestors are installed before making final battery termination

connections. Use caution not to over-tighten.

4.5 Numbering cells, labels and warnings for battery

C&D TECHNOLOGIES, INC. provides labels and warnings to help you maintain

your battery and to apprise you of certain hazards.

Be certain to attach

maintenance and operating labels to cells so they may be read by anyone

working on or in the vicinity of the battery. Reference Part 4, para 1.9 for

examples.

Every cell has an identification label on the cover. This label is very important

since it lists cell type, date code, and order number. This information is needed for

warranty purposes.

The cell ID label is usually placed prior to shipment at the factory. However, some

cells are prepacked in order to enhance delivery. In this case, the ID labels will be

shipped separately and must be placed by the installer during installation.

For ease of identification, all cells of a battery should be numbered. Plastic peel-

and-stick numbers are furnished in the accessories package. Common practice is

to start with “1” at the positive terminal of the battery and follow the electrical circuit

with succeeding numbers. Remove the plastic backing and firmly press the number

into position on the appropriate cell. Be careful not to scratch the plastic jar.

FIGURE 1.4.4 - Flame arrestor vent

with dust cover

Example of an ID label.

Note: Depending on the EP

rack type, spacers

provided may be foam

or molded PVC.

PART 1

RECEIVING AND INSTALLATION (CONTINUED)

RS1476/0215/CD

9

www.cdtechno.com

Note: This is a good time to confirm proper cell orientation, insuring correct polarity

and terminal location (i.e. positive to negative to positive, etc.).

4.6 Preparing electrical contacting surfaces

All electrical contacting surfaces must have a clean, electrolyte-free finish. Any tarnish or discoloration should be

removed with the plater’s brass bristle brush,optional fiber bristle brush, burlap cloth, or medium grade Scotch Brite™.

CAUTION

Where multiple standard type racks are installed end-to-end, no more than one-eighth-

inch of cell length should rest over a support rail that is not rigidly spliced.