C&D Technologies RS-1476 Standby Battery Vented Cell User Manual

Page 32

APPENDIX B - MATERIAL SAFETY DATA SHEET

Please refer to C&D’s website at www.cdtechno.com/resource/msds.html for the latest material safety data sheet

information; 14-324 Flooded Lead-Calcium Batteries and 14-326 Sulfuric Acid, Battery Electrolyte.

APPENDIX C - SPILL CONTAINMENT

Introduction:

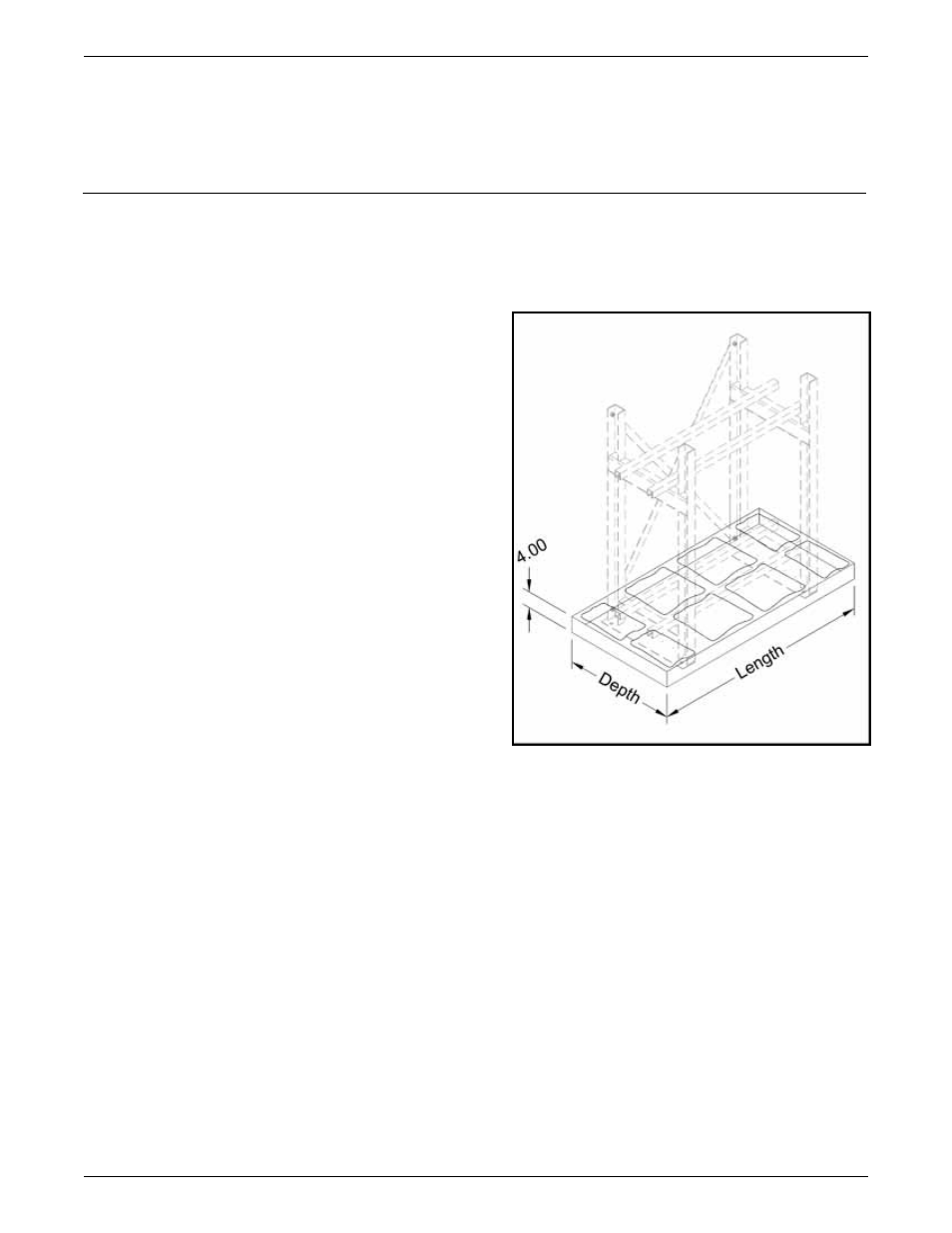

Spill containment systems are used to contain and absorb/

neutralize the release of battery electrolyte from damaged lead

acid batteries used in stationary applications. Spill containment

systems are designed with the minimal number of components

for ease of installation and overall simplicity. Components may

vary from supplier to supplier, yet all systems produce the same

results. Components include a 4” high barrier that is typically

bolted to the floor with sealed seams and joints. The floor

can either be coated with an epoxy paint or have a protective

liner. The barriers and the floor must create a watertight area

and must be impervious to the liquid being stored. The final

component is the pillows, which can absorb or neutralize and

absorb the battery electrolyte. C&D only provides neutralizing

and absorbing pillows. All components have a flame retardant

rating, contact your local C&D representative for additional

information.

Compliance:

Spill containment systems are required to comply with

various codes used for building safety when stationary lead

acid batteries systems have been installed. The decision to

use spill containment systems is based on local, regional,

state or national codes as directed by the authority having

jurisdiction (AHJ). C&D does not decide or require the use of

spill containment systems for our customers. However, C&D

recommends the use of any methods and products that assure

building and battery room safety for our customers.

Spill containment systems suppliers:

Spill containment systems offered by (C&D) with or without

our stationary batteries are designed to meet or exceed all requirements and specifications set forth by all applicable

codes pertaining to stationary lead-acid batteries and battery room safety. Our suppliers warrant these products

and copies are available. C&D will provide information on the available spill containment systems including any

specifications or third party testing and verification if requested.

Selection:

C&D has determined which spill containment systems will fit our existing battery racks. Additionally, custom sizes are

available with exact dimensions or room layouts. For proper compliance, the inside of the barrier area must have a 1”

perimeter around the shadow area of the battery rack.

Installation:

Provided with the spill containment system are instructions for proper installation with diagrams and a bill of materials

or packing list. In most cases, the installation of spill containment systems should be made prior to the installation of

the battery rack. If a spill containment system is to be installed after the installation of the battery rack, please consult

with your C&D representative to determine which spill containment system will be best for this situation.

FIGURE C.1 - Spill containment barriers with pillows

RS1476/0215/CD

30

www.cdtechno.com