C&D Technologies RS-1476 Standby Battery Vented Cell User Manual

Page 14

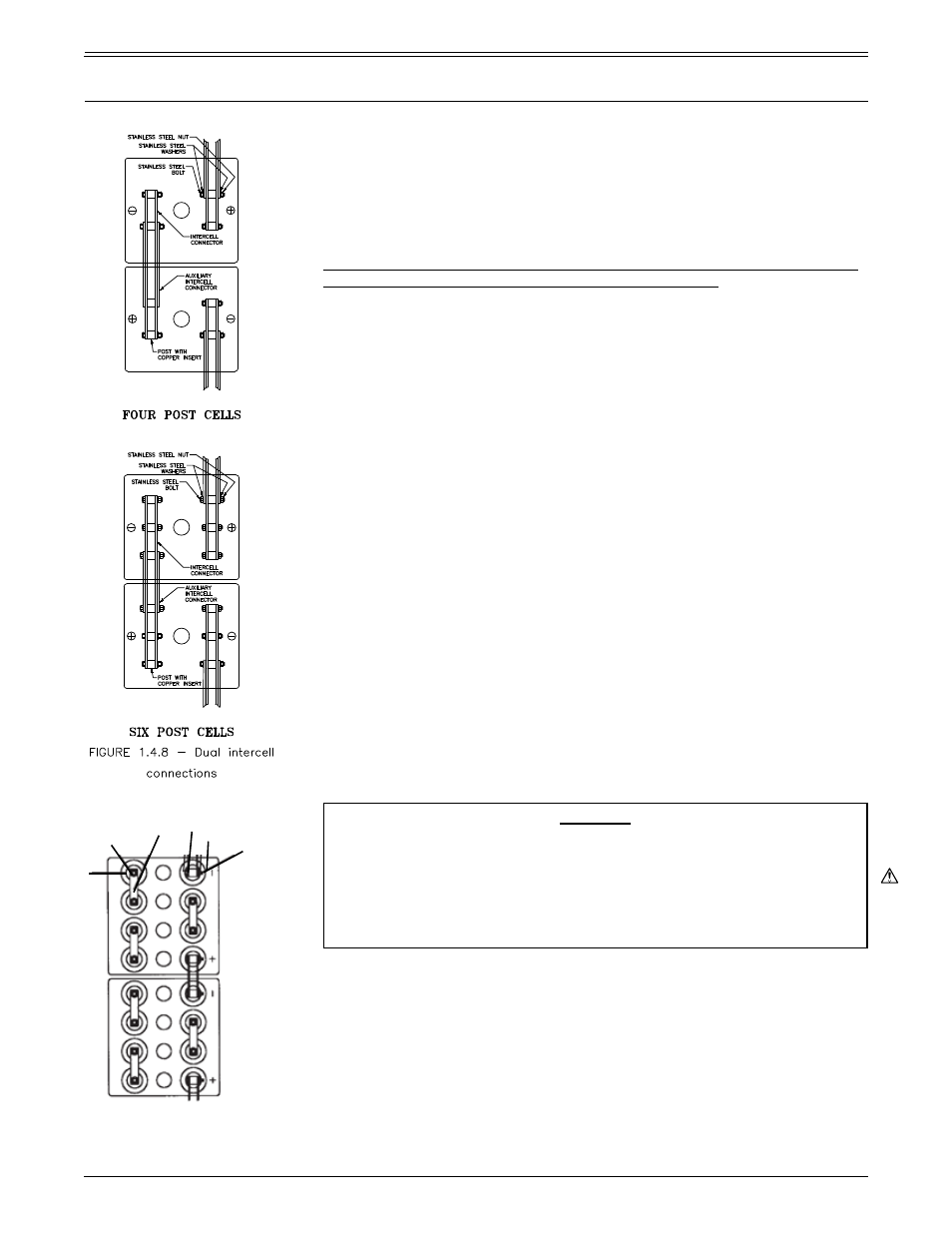

When two inter-cell connectors are supplied for connecting cells they must be

placed on opposite sides of the posts. Make the inter-cell connection (positive to

negative) using the bolt assemblies supplied. Refer to Figure 1.4.5.

High current batteries may use shorter piggy back inter-cell connectors

applied over the top of the full length inter-cell connectors connecting all

posts. See illustrations for four and six post cells, Figure 1.4.8.

Tighten the connections to the torque values specified in Table 3, using a torque

and box wrench in counter-torque to avoid damaging posts.

4.8 Checking connection integrity

After connecting and torquing all cells in the battery and prior to connecting to

the charger or dc system, recheck the torque of all connections, in sequence,

and immediately check the total voltage of the battery, using a digital dc

voltmeter. Total battery voltage should equal the open circuit voltage (Table

2) of an individual cell multiplied by the number of cells in series connection.

The cell nameplate provides information on the specific gravity of your cell(s).

Refer to Part 4, Section 1.9, for description of nameplate information.

If the battery voltage is less than this value, either your voltmeter is incorrect

or one or more of the cells is installed in reverse polarity. Check and correct

cell polarities. Making this correction will avoid the possibility of charging cells

in reverse and destroying them.

Initial cleaning, surface preparation and torquing establishes the lowest

possible resistance between posts, connectors and lugs – all of which may

have somewhat irregular surface finishes. Subsequent retightening at slightly

lower maintenance torque value (reference table 3) periodically restores initial

connection integrity between clean surfaces.

Over-torquing will distort lead

posts, permanently damaging the cells.

Maintain clean, tight connections. Per Part 4 of this manual, check connection

resistance. Connection maintenance is the responsibility of the battery end

user. Refer to Part 4 for additional maintenance information.

The preferred method of checking connection integrity is by using a digital low

resistance micro-ohm meter (DLRO) and recording the resistance values of

each connection. For new installations remake any connection that is more

than 10 percent above the average value or 5 micro-ohms, whichever is

greater. Refer to the Reference section (Part 4) of this manual for additional

information and IEEE-450 and 484 professional standards.

CAUTION

It is the sole responsibility of the battery end user to check connections.

All connections should be checked at regular intervals, to ensure the

connections are clean and tight. Never operate a battery with loose or

corroded connections. When restoring connections, disconnect the

battery from the load and the charging equipment and follow all the

precautionary measures outlined above.

4.9 Terminal plates, cables and lugs

C&D TECHNOLOGIES, INC. offers a variety of cables, terminal lugs and

special terminal plates as optional equipment for specific battery installations.

Before beginning installation, check the accessories cartons to determine if

the parts ordered have been received. Also check for additional instructions

which may be specific to your application. This should be done before you

schedule installation to permit delivery of any necessary additional hardware.

Standard length inter-row and inter-tier (not inter-aisle or charger) cables are

supplied by C&D. They are flexible, battery cables with lugs, properly sized for

minimal voltage drop. Lead plated lugs are supplied when lugs are attached to

the battery posts.

TWO POST

MULTICELL

STAINLESS STEEL BOLT

STAINLESS

STEEL WASHER

STAINLESS STEEL NUT

INTER-CELL

CONNECTOR

STAINLESS STEEL BOLT

AND WASHER

POST WITH

COPPER

INSERT

PART 1

RECEIVING AND INSTALLATION (CONTINUED)

RS1476/0215/CD

12

www.cdtechno.com