C&D Technologies RS-1476 Standby Battery Vented Cell User Manual

Page 12

DO NOT REMOVE LEAD PLATING

To maintain electrical contact integrity, C&D supplies NO-OX-ID grease (in the accessories package) as a

corrosion resistant coating for all bolted electrical contacting surfaces. For optimum connection integrity, C&D

recommends the following procedure:

Cell posts are typically factory coated with either NO-OX-ID grease or oil in the factory and may be covered with a

plastic cap to prevent oxidation of the lead during transportation and storage.

1. Remove any factory-applied coating from the posts and post seals with a dry cloth as they may be

contaminated with dirt or residual acid. NOTE: Post seals may appear wet due to the oil.

2. With a neutralizing solution consisting of one pound sodium bicarbonate mixed with one gallon water, wipe the

cover, post and post seal with a cloth or fiber bristle brush moistened with the neutralizing solution. Rinse with

clean water and dry thoroughly.

DO NOT USE ANY INDUSTRIAL BATTERY CLEANERS AS THIS WILL VOID

WARRANTY!

CLEANING OF BATTERIES WITH WATER OR ISOPROPYL ALCOHOL ALONE WILL NOT NEUTRALIzE ACID.

3. Lightly brush the post and lead ring of the post seal with the plater’s brass brush (provided in the accessories),

or medium grade Scotch Brite™ to provide a clean bright finish.

NEVER USE STEEL BRUSHES OR OTHER

ABRASIVE TOOLS OR MATERIALS. Cells designed for high discharge currents are constructed with tin flashed

copper inserts cast within the lead posts to optimize conductivity. The copper faces should be lightly brushed to

minimize scratching or removal of this tin flashing.

Note: Incidental copper exposure on posts due to handling and installation will neither degrade battery

performance nor reduce the battery’s expected operating life when properly maintained.

4. Carefully remove any oxidation or white powder from the inter-cell connectors’ mating surfaces with either

the plater’s brass brush, fiber bristle brush, a piece of burlap cloth, or medium grade Scotch Brite™ and buff to

a clean and uniform finish. Inter-cell connectors are lead plated copper and require that care be taken not to

remove the plating.

5. Heat the NO-OX-ID grease to a cream like consistency using a thermostatically controlled hot plate (with no

open flames). Set the temperature between 160°F (71°C) to 185°F (85°C) to maintain the desired consistency.

NO-OX-ID grease must be applied to the terminal post and to the horizontal lead surface of the post seal to

ensure all exposed lead is properly coated to protect against surface discoloration.

Apply a

thin coat of grease to each end of the inter-cell connectors (where they will

make contact with posts). On four and six-hole connectors, use a one-inch paint brush to

apply NO-OX-ID grease to both sides of the middle holes and to cell posts. To achieve a

continuous film of protective NO-OX-ID grease finish the completely assembled battery

with a hot air gun or blower. Wipe any excess NO-OX-ID grease from the cover(s).

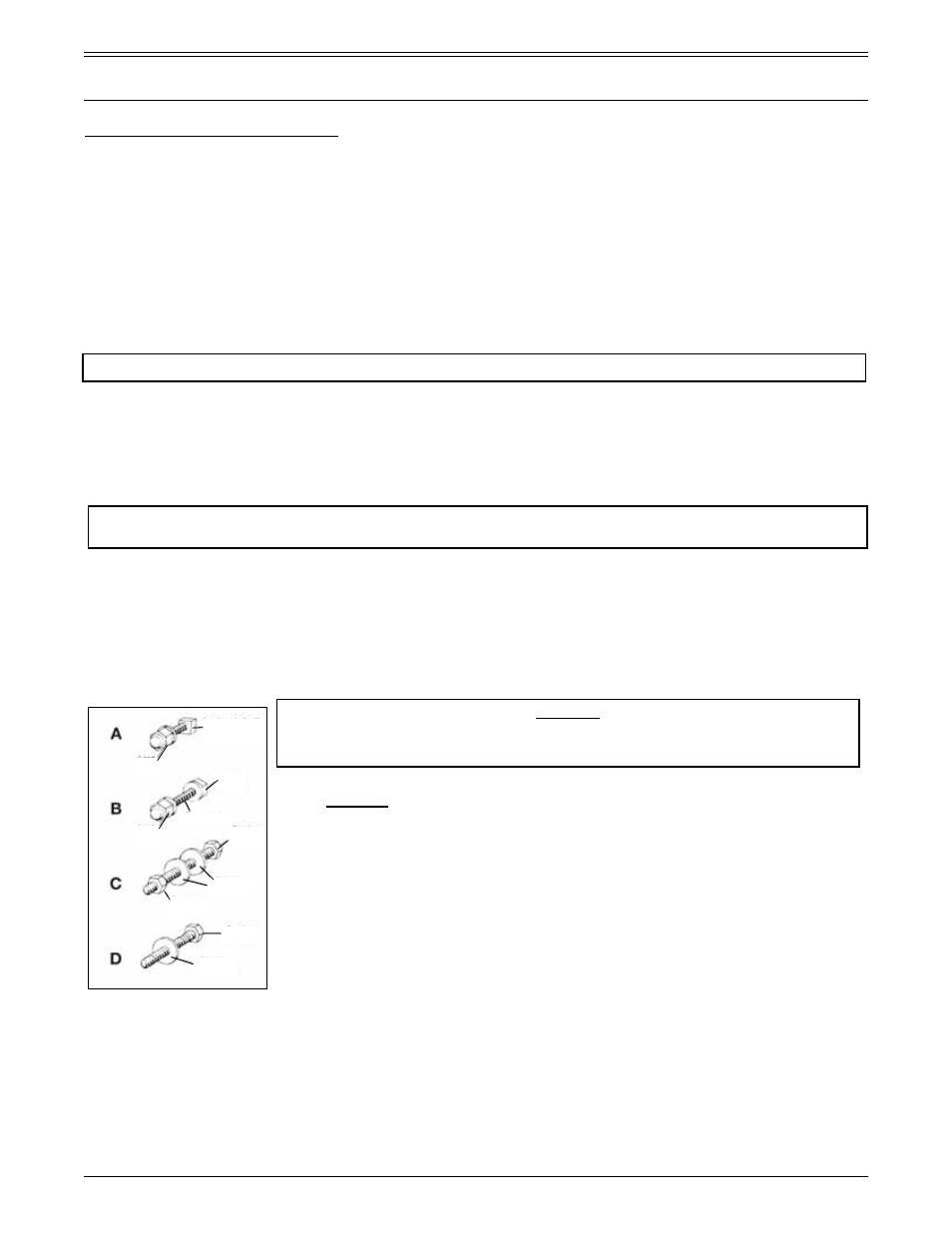

4.7 Making the connections

C&D batteries are supplied with stainless steel connecting hardware; optional lead-brass

hardware is available (see Figure 1.4.5 & Table 3).

Cells are supplied with different post configurations suited to their current handling requirements, see Figure 1.4.6.

Place inter-cell connectors against cell posts and insert C&D supplied brass stud or stainless steel bolt through

the bolt hole in the post and the hole in the connector. For stainless steel bolts, install heavy-duty washers, bolts

and nuts. Ensure the sharp edge of the stamped steel washer is facing away from the inter-cell connector. Hand

tighten. Where one brass stud and two lead capped nuts are supplied, be sure that an equal number of threads is

engaged on each nut.

FIGURE 1.4.5 - Connecting bolt

assemblies.

PART 1

RECEIVING AND INSTALLATION (CONTINUED)

Lead cap bolt

with brass

threads

Lead

cap nut

Brass stud

2 stainless

steel washers

Lead

cap nut

Lead

cap nut

Stainless

steel bolt

Stainless

steel nut

Stainless

steel washer

Stainless

steel bolt

RS1476/0215/CD

10

www.cdtechno.com

CAUTION

If the hot plate does not have a thermostatic control, exercise extreme care to

avoid overheating the grease and causing a fire. Do not use open flames.

NO-OX-ID grease has a minimum flash point of 450°F (232°C).

Type

Hardware Description

A 1/4 - 20 brass bolt with cast-on head and brass-inserted cast lead nut.

B 5/16 - 18 brass stud and two brass-inserted cast lead nuts.

C Stainless steel hexagonal bolt, two flat washers, and hexagonal nut.

D Stainless steel hexagonal bolt and one flat washer.