7 - maintenance, Maintenance, Installation, operation & maintenance – AERCO Modulex General Manual User Manual

Page 45

INSTALLATION, OPERATION & MAINTENANCE

7-1

MAINTENANCE

7.1 - MAIN FEATURES

If the boiler is correctly adjusted, it needs very little maintenance. It only needs to be checked once a

year and, if necessary, be cleaned. See the Annual Maintenance Schedule in Table 7-1 at the end of

this section. any case the frequency of the cleaning depends on the cleanliness of the air for the

combustion. Dust presence in the air will find its way into the combustion chamber, will increase

resistance, and will result in a reduced heat input and consequently a reduced output.

Before washing the boiler body sections, check the

boiler input and the CO

2

percentage. If the actual

input (with the correct CO

2

) is within 5% of the

value shown in paragraph 1.5, the boiler does not

need to be cleaned. The operation then can be

limited to the cleaning of the condensate drain.

NOTE: A reduction of the input can be caused by the obstruction of the flue outlet or of the air intake.

Check, first of all, that this is not the reason.

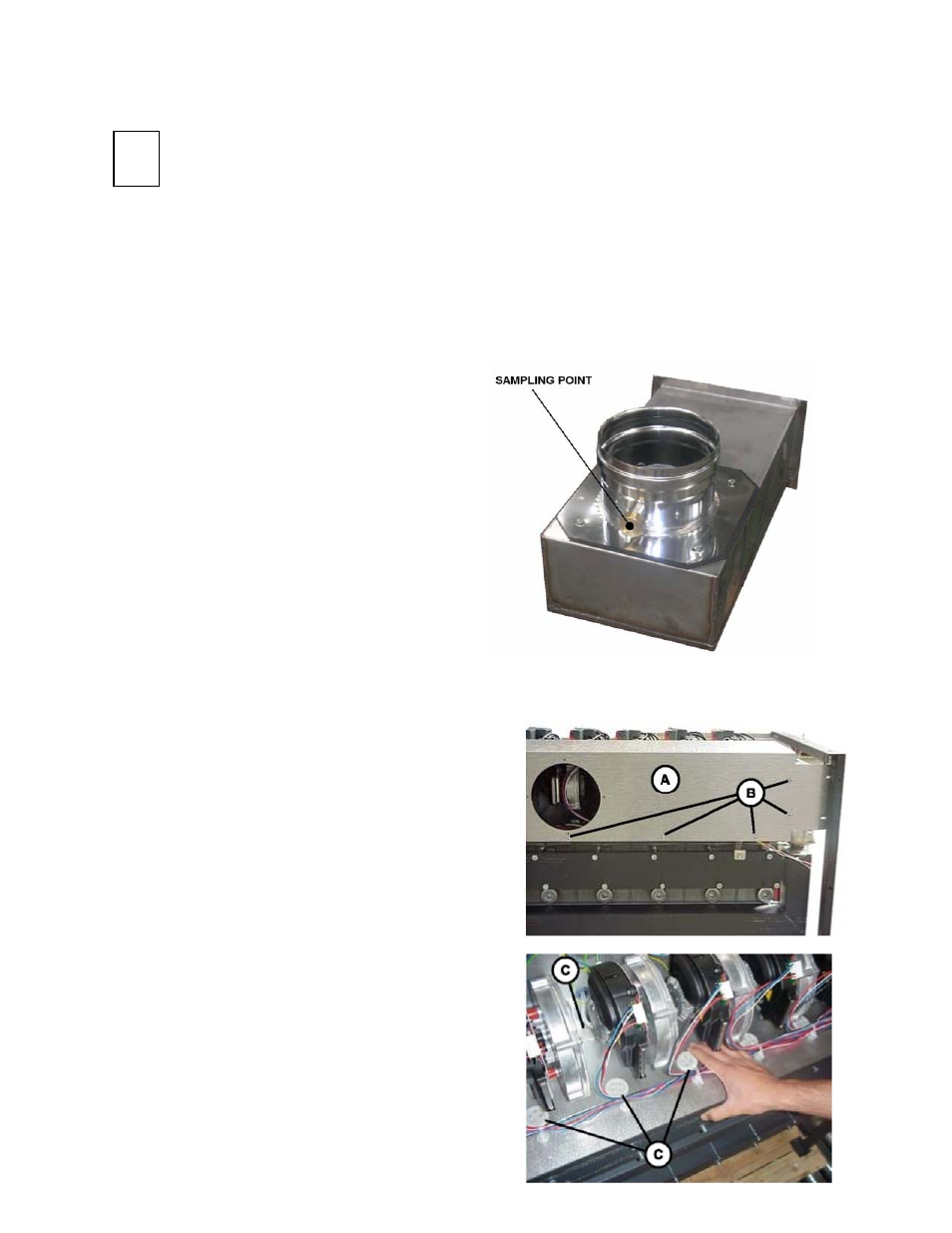

Disassembly

1. Switch off power and gas supply and verify that

the gas cock is fully closed.

2. Unscrew the union at the gas inlet.

3. Remove the front, rear and top panels of the

boiler.

4. After the removal of “B” screws, remove the

cover “A” of the fan chamber.

5. Remove the diaphragms “C” from the bottom of

the fan chamber to get access to the screws

securing the burner covers.

6. Using a 13 mm socket wrench, remove the

screws “D1 – D2 – D3 – D4”, securing the

burner covers.

7