Installation, operation & maintenance – AERCO Modulex General Manual User Manual

Page 42

INSTALLATION, OPERATION & MAINTENANCE

6-8

NOTE

The CASCADE MANU (Cascade Manual) mode will time out after a period of 15 minutes.

When this occurs, the boiler will revert the Auto mode and will function under program

control. If this occurs prior to completing the combustion calibration for each Boiler stage,

it will be necessary to repeat steps 7 through 15 and then sequence the Boiler stage to

the one which was in-process when the time out occurred.

11. Turn the Rotary Knob clockwise until CASCADE MANU is displayed.

12. Press the Program Key. BOILER 1 will be displayed.

13. Press the Program Key again. The display will show CODE NO., requesting the valid code to be

entered.

14. Enter code 0000 (4 zeros) by pressing the Program Key four times. The red LED will remain lit

while the four code digits are entered. The LED will turn off after the last code digit is entered.

15. With BOILER 1 displayed, press the Program Key. The red LED will light.

16. Turn the Rotary Knob clockwise and select a fire rate of 10%. Press the Program Key to store the

setting.

17. Wait until the first Boiler stage fires and stabilizes at the 10% fire rate.

18. Insert the combustion analyzer probe into the 3/8” hole in the flue. Allow enough time for the

combustion analyzer to settle.

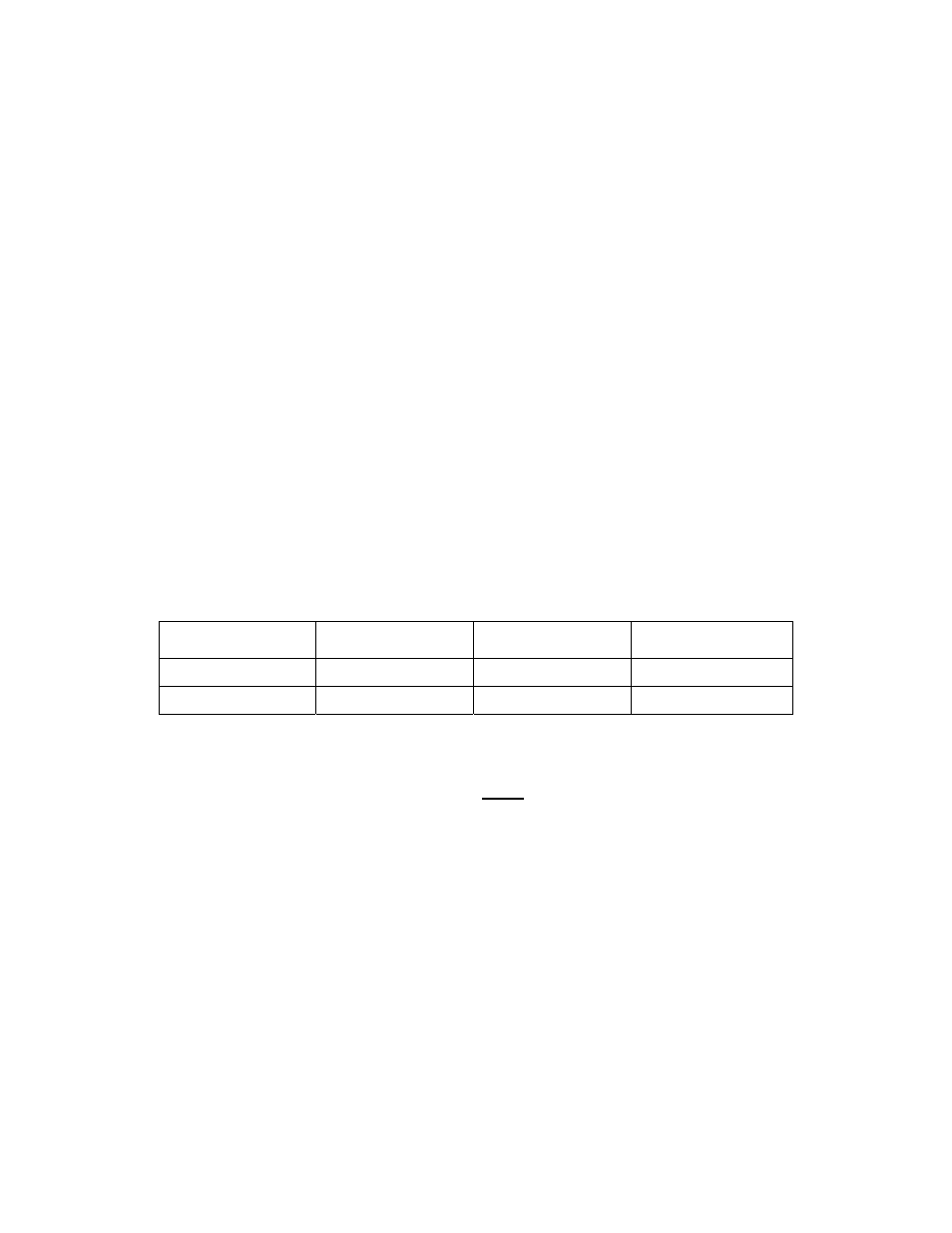

19. Verify that the oxygen (O

2

) level is within the range shown below. Also, ensure that the carbon

dioxide (CO

2

) and carbon monoxide (CO) are within the ranges shown.

GAS SUPPLY

OXYGEN (O

2

)

CARBON

DIOXIDE (CO

2

)

CARBON

MONOXIDE (CO)

NATURAL GAS

4.7% to 5.3%

9.1% to 8.8%

<100 ppm

PROPANE

4.4% to 5.0%

10.7% to 10.4%

<100 ppm

20. If the oxygen level is not within the required tolerance, the gas valve (Figure 6-2) for the Boiler

stage must be adjusted. This is accomplished by removing the cap shown in Figure 6-2 using a

T40 Torx tool. Once the cap is removed, slowly rotate the internal valve adjustment screw

(approximately 1/4 turn increments). Allow time for the combustion analyzer to stabilize following

each gas valve adjustment. Clockwise rotation reduces the oxygen level, while counterclockwise

rotation increases the oxygen level.

21. Once the oxygen level is within the required range for the first BOILER stage, measure the gas

pressure at the outlet pressure tap. The pressure should be approximately 0.50” W.C. at the 10%

fire rate.

22. Press the Program Key.

23. Using the Rotary Knob, set the displayed fire rate to zero. Press the Program key and wait until

the Boiler stage turns off.

24. This completes the combustion calibration procedure for the first BOILER stage.

25. Disconnect the manometer connected in step 3 and close the outlet pressure tap.

26. Turn the Rotary Knob clockwise to the next Boiler stage. Repeat steps 16 through 25 for each

remaining Boiler stage (up to 7, depending on boiler size).