Initial start-up – AERCO KC1000 Low NOx Boiler equipped with C-More version 3.04 User Manual

Page 39

INITIAL START-UP

14. Use a flat-tip screwdriver to adjust the

differential pressure regulator. Turn the

screwdriver:

• counterclockwise to increase the

oxygen level

• clockwise to decrease the oxygen level

15. Replace the regulator cap and cap gasket

and wait for the analyzer reading to settle.

16. When the analyzer reading settles, compare

the new oxygen reading to Table 4.

17. If necessary, repeat the adjustment until the

oxygen level is within the range specified in

Table 4.

18. Replace the regulator cap and cap gasket.

NOTE:

Adjust only the differential regulator at 30%

control signal; do not adjust the air shutter.

19. Once the oxygen level is within the specified

range at 30%, change the valve position to

16%.

20. Oxygen levels at the 16% valve position

should be as shown in Table 5. Also, ensure

that the CO and NOx readings do not

exceed the values shown. No adjustment

should be necessary. Contact AERCO if the

oxygen, CO or NOx levels are not within the

specified ranges.

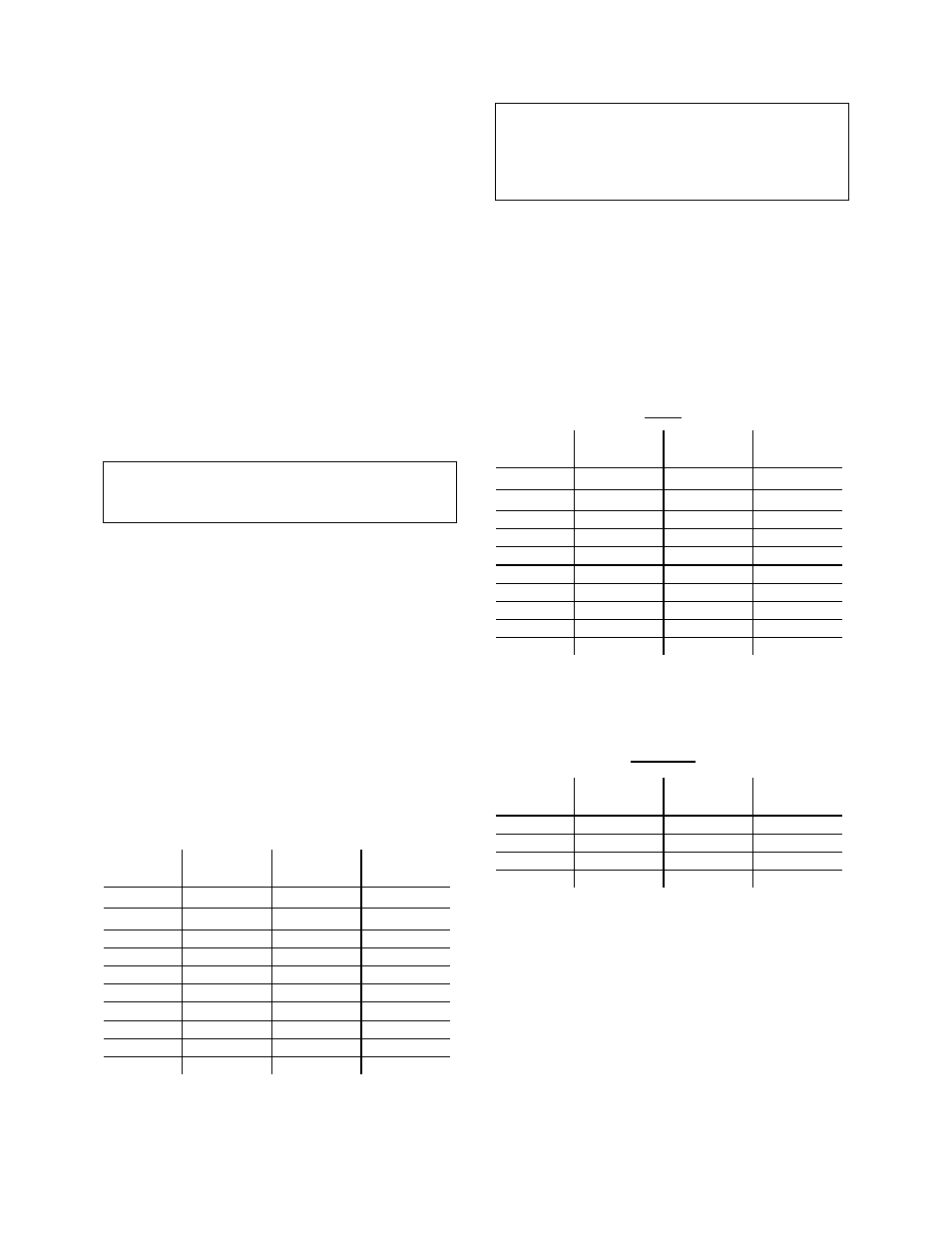

Table 5

Combustion Oxygen Levels for a 16%

Valve Position

Inlet Air

Temp

Oxygen

(±0.2%)

Carbon

Monoxide

*NOx

-25°F <10%

<100

ppm

<30

ppm

-10°F <10%

<100

ppm

<30

ppm

0°F <10%

<100

ppm

<30

ppm

10°F <10%

<100

ppm

<30

ppm

25°F <10%

<100

ppm

<30

ppm

40°F <10%

<100

ppm

<30

ppm

55°F <10%

<100

ppm

<30

ppm

70°F <10%

<100

ppm

<30

ppm

85°F <10%

<100

ppm

<30

ppm

100°F <10%

<100

ppm N/A

* NOx readings corrected to 3% oxygen.

NOTE:

At a 100% valve position, the KC1000 will not

operate reliably at inlet air temperatures below

55°F if the Cold Air Damper (P/N 99026) is not

installed. See paragraphs 2.8.2 and 2.8.3.

21. Change the valve position to 100% and allow

the combustion analyzer to settle. If the

optional Cold Air Damper (P/N 99026) is

installed, compare the measured oxygen

level with the levels in Table 6. If the Cold Air

Damper is not installed, compare the oxygen

levels with the readings in Table 6A.

Table 6

Combustion Oxygen Levels for a 100%

Valve Position With Cold Air Damper

Inlet Air

Temp

Oxygen

(±0.2%)

Carbon

Monoxide

*NOx

-25°F

5.9

<100 ppm

<30 ppm

-10°F

5.7

<100 ppm

<30 ppm

0°F

5.6

<100 ppm

<30 ppm

10°F

5.5

<100 ppm

<30 ppm

25°F

5.4

<100 ppm

<30 ppm

40°F

5.3

<100 ppm

<30 ppm

55°F

5.1

<100 ppm

<30 ppm

70°F

5.0

<100 ppm

<30 ppm

85°F

4.8

<100 ppm

<30 ppm

100°F 4.1

<100

ppm N/A

* NOx readings corrected to 3% oxygen.

Table 6A

Combustion Oxygen Levels for a 100%

Valve Position Without Cold Air Damper

Inlet Air

Temp

Oxygen

(±0.2%)

Carbon

Monoxide

*NOx

55°F

6.7%

<100 ppm

<30 ppm

70°F

5.7%

<100 ppm

<30 ppm

85°F

4.7%

<100 ppm

<30 ppm

100°F 3.9%

<100

ppm N/A

* NOx readings corrected to 3% oxygen.

21. If the measured oxygen reading is below the

oxygen range in Table 6 (or 6A), loosen the

two bolts that secure the inlet air shutter to

the unit using a 7/16” wrench (see

Figure 4.4). Open the shutter 1/4” to 1/2” to

increase the oxygen level, then tighten the

nuts.

4-7