Figure 4.3, Differential regulator, Initial start-up – AERCO KC1000 Boiler equipped with C-More 2002 User Manual

Page 49

INITIAL START-UP

4-3

NOTE:

On initial start-up, or return to service from a

fault condition, the unit will remain at a 29% firing

rate for two-minutes, although the control signal

may indicate a greater input.

9. Following the warm-up period, increase the

firing rate in 20% increments while monitor-

ing the gas pressure after every increase. If

gas pressure dips below 8.5” W.C. for FM

gas trains and 8.9” for IRI gas trains at any

input percentage, stop and raise the

pressure. Once 100% is reached, adjust the

gas pressure for 8.5” W.C. or 8.9” W.C.

NOTE:

If 8.5” W.C. for FM gas trains or 8.9” W.C. for IRI

gas trains cannot be obtained at the 100% firing

rate, it will be necessary to stop calibration and

contact the local AERCO representative in your

area. Running the unit on insufficient gas

pressure will void the warranty

10. Once 8.5” W.C. or 8.9” W.C. is set at the

100% level, change the firing rate to 30%

and insert the combustion analyzer probe

into the stack.

NOTE:

Always go to a percentage of firing rate from the

same direction, (i.e., 100% to 30% or 30% to

20%). Whenever going to a firing rate from

below (i.e., 20% to 30%), first go above then

back down to the desired firing rate. This is

necessary due to hysteresis in the air/fuel

stepper motor. Hysteresis causes the air/fuel

valve to stop in a slightly different position if the

firing rate percentage is approached from below

or above. This results in a difference in oxygen

readings for the same firing rate percentage

causing unnecessary recalibration.

11. Allow enough time for the combustion

analyzer to settle. Compare the measured

oxygen level to the oxygen range for the

existing intake air temperature in Table 1.

12. If the measured oxygen level is within the

range listed in Table 1, no adjustment is

necessary. Proceed to step 19.

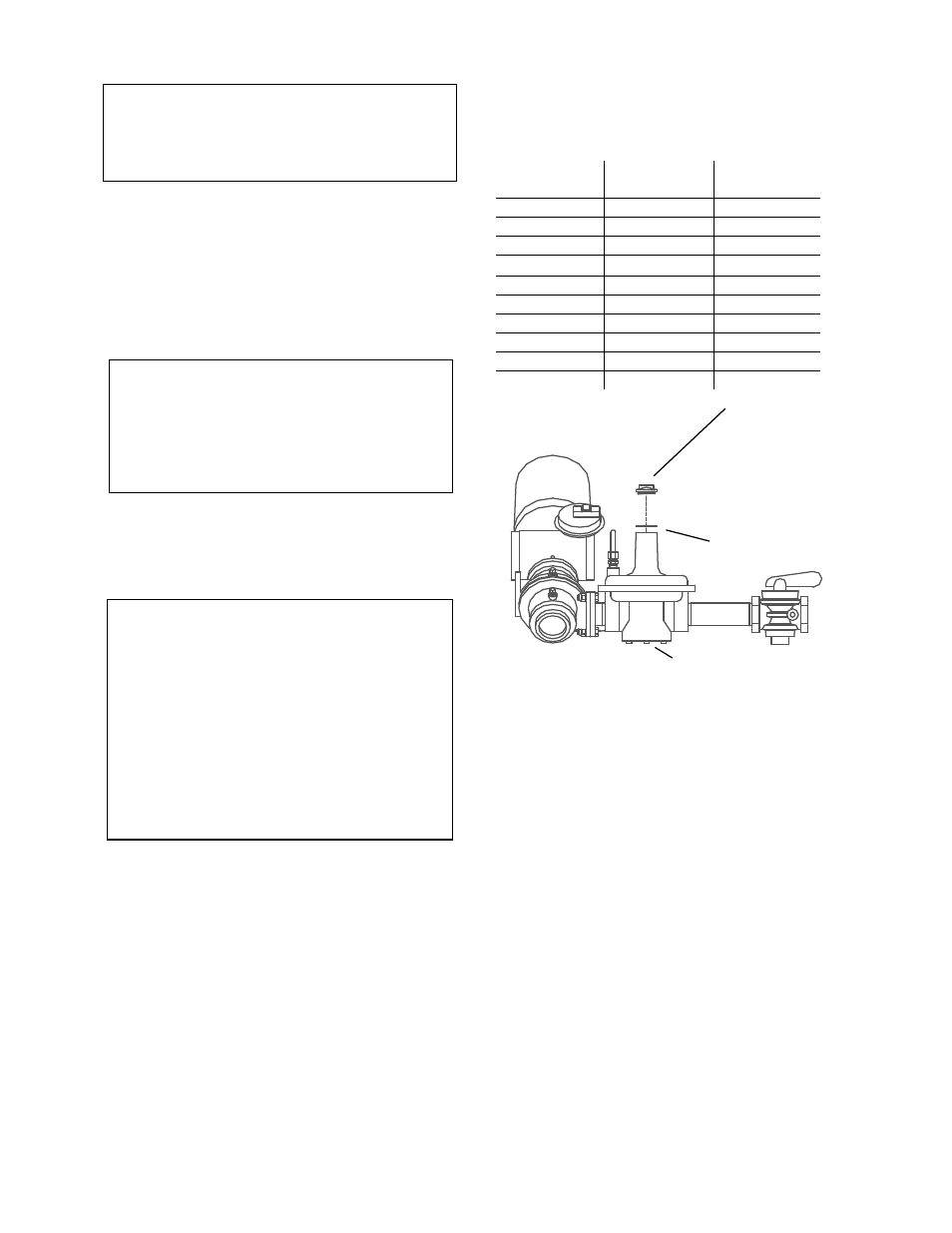

13. If the measured oxygen level is not within

the range listed in Table 1, remove the

regulator cap and cap gasket from the

differential pressure regulator (see

Figure 4.3) and proceed to step 14.

Table 1

Combustion Oxygen Levels for a 30%

Firing Rate

Inlet Air

Temp

Oxygen

(+0.2/-1.0)

Carbon

Monoxide

-20°F

7.5 %

<50 ppm

0°F

7.3 %

<50 ppm

10°F

7.2 %

<50 ppm

30°F

6.8 %

<50 ppm

50°F

6.4 %

<50 ppm

60°F

6.2 %

<50 ppm

70°F

6.0 %

<50 ppm

80°F

5.8 %

<50 ppm

90°F

5.6 %

<50 ppm

100°F

5.4 %

<50 ppm

DIFFERENTIAL

PRESSURE

REGULATOR

REGULATOR CAP

CAP GASKET

Figure 4.3

Differential Regulator

14. Use a flat-tip screwdriver to adjust the

differential pressure regulator. Turn the

screwdriver:

• counterclockwise to increase the

oxygen level

• clockwise to decrease the oxygen level

15. Replace the regulator cap and cap gasket

and wait for the analyzer reading to settle.

16. When the analyzer reading settles, compare

the new oxygen reading to Table 1.

17. If necessary, repeat the adjustment until the

oxygen level is within the range specified in

Table 1.

18. Replace the regulator cap and cap gasket.