1 constant setpoint mode, Figure 2.11, I/o box terminal strip – AERCO KC1000 Boiler equipped with C-More 2002 User Manual

Page 17: Boiler management system (bms) mode, 4 remote setpoint and direct drive modes, Installation, 2 indoor/outdoor reset mode, Danger

INSTALLATION

2-7

2.6.1 CONSTANT SETPOINT MODE

The Constant Setpoint Mode is used when it is

desired to have a fixed setpoint that does not

deviate. No wiring connections other than

electrical supply connections are required for

this mode. However, if desired, fault monitoring

or enable/disable interlock wiring can be utilized

(see paragraphs 2.7.9 and 2.7.10).

2.6.2 INDOOR/OUTDOOR RESET MODE

This mode of operation increases supply water

temperature as outdoor temperatures decrease.

An outside air temperature sensor (AERCO PN

122790) is required. The sensor MUST BE

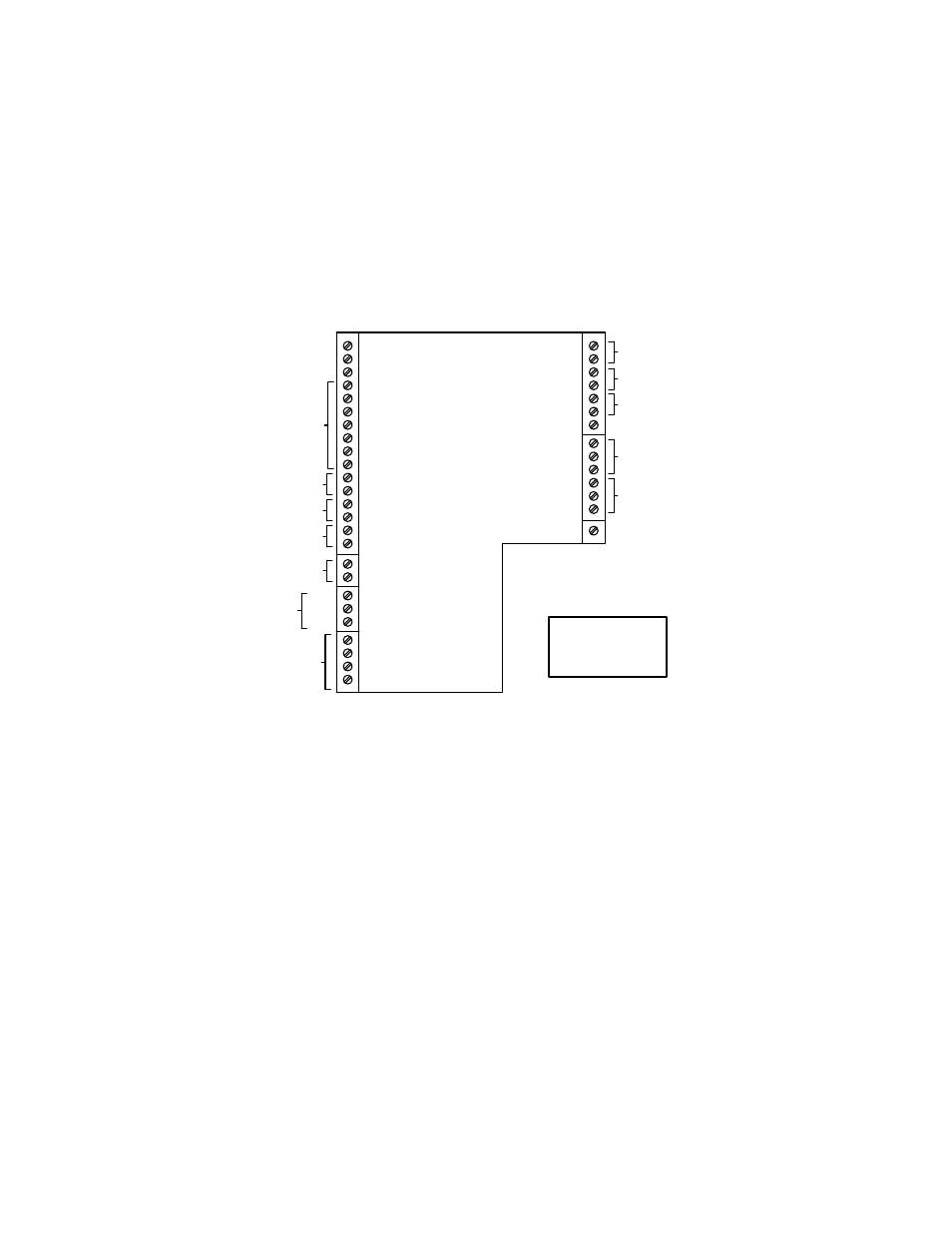

wired to the I/O Box wiring terminals (see Fig.

2.11). For more information concerning the

outside air sensor installation, refer to paragraph

2.7.1. For programming and setup instructions

concerning the indoor/outdoor-reset mode of

operation, refer to Section 5, paragraph 5.1.

.

mA OUT

RS-485

COMM.

+

-

+

-

ANALOG IN

SENSOR COMMON

OUTDOOR SENSOR IN

REMOTE INTL'K IN

B.M.S. (PWM) IN

SHIELD

+

-

+

-

AUX SENSOR IN

NOT USED

EXHAUST SWITCH IN

DELAYED INTL'K IN

FAULT RELAY

120 VAC, 5A, RES

AUX RELAY

120 VAC, 5A, RES

G

RELAY CONTACTS:

120 VAC, 30 VDC

5 AMPS RESISTIVE

DANGER

120 VAC USED

IN THIS BOX

NOT USED

NOT USED

NC

COM

NO

NC

COM

NO

NOT USED

Figure 2.11

I/O Box Terminal Strip

2.6.3 BOILER MANAGEMENT SYSTEM

(BMS) MODE

NOTE

BMS Model 168 can utilize either pulse

width modulation (PWM) or RS485

Modbus signaling to the Boiler. BMS II

Model 5R5-384 can utilize only RS485

signaling to the Boiler.

When using an AERCO Boiler Management

System (BMS), the field wiring is connected

between the BMS Panel and each Boiler’s I/O

Box terminal strip (Figure 2-11). Twisted

shielded pair wire from 18 to 22 AWG must be

utilized for the connections. The BMS Mode can

utilize either pulse width modulation (PWM)

signaling, or RS485 Modbus signaling. For PWM

signaling, connections are made from the

AERCO Boiler Management System to the

B.M.S. (PWM) IN terminals on the I/O Box

terminal strip. For RS485 Modbus signaling,

connections are made from the BMS to the

RS485 COMM terminals on the I/O Box terminal

strip. Polarity must be maintained and the shield

must be connected only at the AERCO BMS.

The boiler end of the shield must be left floating.

For additional instructions, refer to Chapter 5,

paragraph 5.6 in this manual. Also, refer to GF-

108M (BMS Model 168) and GF-124 (BMS II

Model 5R5-384), BMS -Operations Guides.

2.6.4 REMOTE SETPOINT and DIRECT

DRIVE MODES

The KC1000 Boiler can accept several types of

signal formats from an Energy Management

System or other source to control either the

setpoint (Remote Setpoint Mode) or firing rate