Troubleshooting – AERCO BMK 1.5 LN Dual Fuel June 2010 User Manual

Page 70

TROUBLESHOOTING

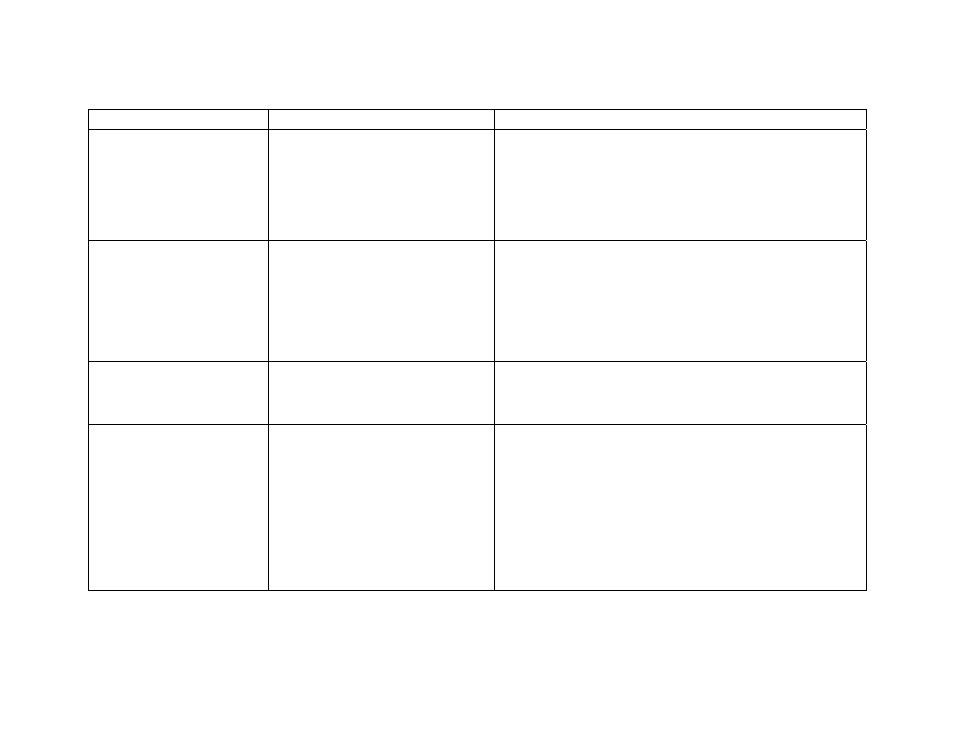

TABLE 8-1. BOILER TROUBLESHOOTING – Continued

FAULT INDICATION

PROBABLE CAUSES

CORRECTIVE ACTION

(continued)

2. Defective ignition switch

3. Defective Power Supply Board or

fuse

4. Defective IGST Board

2. If the Air/Fuel Valve does rotate to the ignition position, check

the ignition position switch for continuity between the N.O. and

COM terminals when in contact with the cam.

3. Check DS1 & DS2 LEDs on Power Supply Board. If they are not

steady ON, replace Power Supply Board.

4. Check “Heartbeat” LED DS1 and verify it is blinking ON & OFF

every second. If not, replace IGST Board.

INTERLOCK

OPEN

1. Interlock jumper not installed or

removed

2. Energy Management System does

not have boiler enabled.

3. Device proofing switch hooked up to

interlocks is not closed.

1. Check for a jumper properly installed across the interlock

terminals in the I/O box

2. If there are two external wires on these terminals check any

Energy Management system to see if they have the units

disabled (a jumper may be temporarily installed to see if the

interlock circuit is functioning).

3. Verify that the proving switch for any device hooked to the

interlock circuit is closing and that the device is operational.

LINE VOLTAGE

OUT OF PHASE

1. Line and Neutral switched in AC

Power Box.

2. Incorrect power supply transformer

wiring.

1. Check hot and neutral in AC Power Box to ensure they are not

reversed

2. Check transformer wiring, in AC Power Box, against the power

box transformer wiring diagram to ensure it is wired correctly

LOW GAS

PRESSURE

1. Incorrect supply gas pressure.

2. Defective low gas pressure switch for

fuel being used

3. Fuel Selector Switch is in the OFF

position or was changed while the

unit was running.

1. Measure gas pressure upstream of the supply gas regulator

with the unit firing. Refer to paragraph 2.7.1 to ensure that the

gas pressure is correct for the type of fuel and gas train being

used

2. Measure gas pressure at the low gas pressure switch. If it is

greater than 2.6” W.C. for the fuel being used, measure

continuity across the switch and replace if necessary.

3. Check Fuel Selector Switch position.

8-8